20

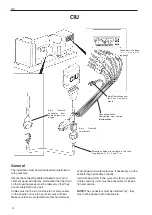

DCU

General

Installation must be planned very carefully and per-

formed with great care.

Fix the connecting cable between the engine and in-

strument panel with clamps. Make sure there is no

mechanical load placed on the connector block, it

must not be subjected to pulling strains.

The cables shall not be drawn close to hot compo-

nents on the engine or close to any other heat source.

Ensure that the cables are protected from mechanical

wear, sharp edges and water splashes. If necessary,

the cables can be feed through conduits.

Avoid having to make splices in the system wiring, if

at all possible. The cables and any splices must be

accessible for inspection and service.

NOTE:

Connectors must be assembled “dry”, they

shall not be filled with Vaseline or similar.

DCU

Summary of Contents for TAD734GE

Page 1: ...EMS 2 Industrial engines TAD734GE Installation 1 1 I ...

Page 2: ......

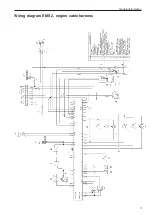

Page 13: ...General information 11 Wiring diagram EMS 2 engine cable harness ...

Page 45: ...43 References to Service bulletins Group No Date Concerning ...

Page 46: ... Notes ...

Page 48: ...7747352 English 10 2009 ...