•

Keep batteries and battery terminals dry and clean.

Oxidation or dirt on the battery and battery terminals

may cause short circuits, voltage drops, and dis-

charges (especially in damp weather).

•

Tighten all battery connections. Loose battery con-

nections may cause damage to the engine’s elec-

trical system.

Drive

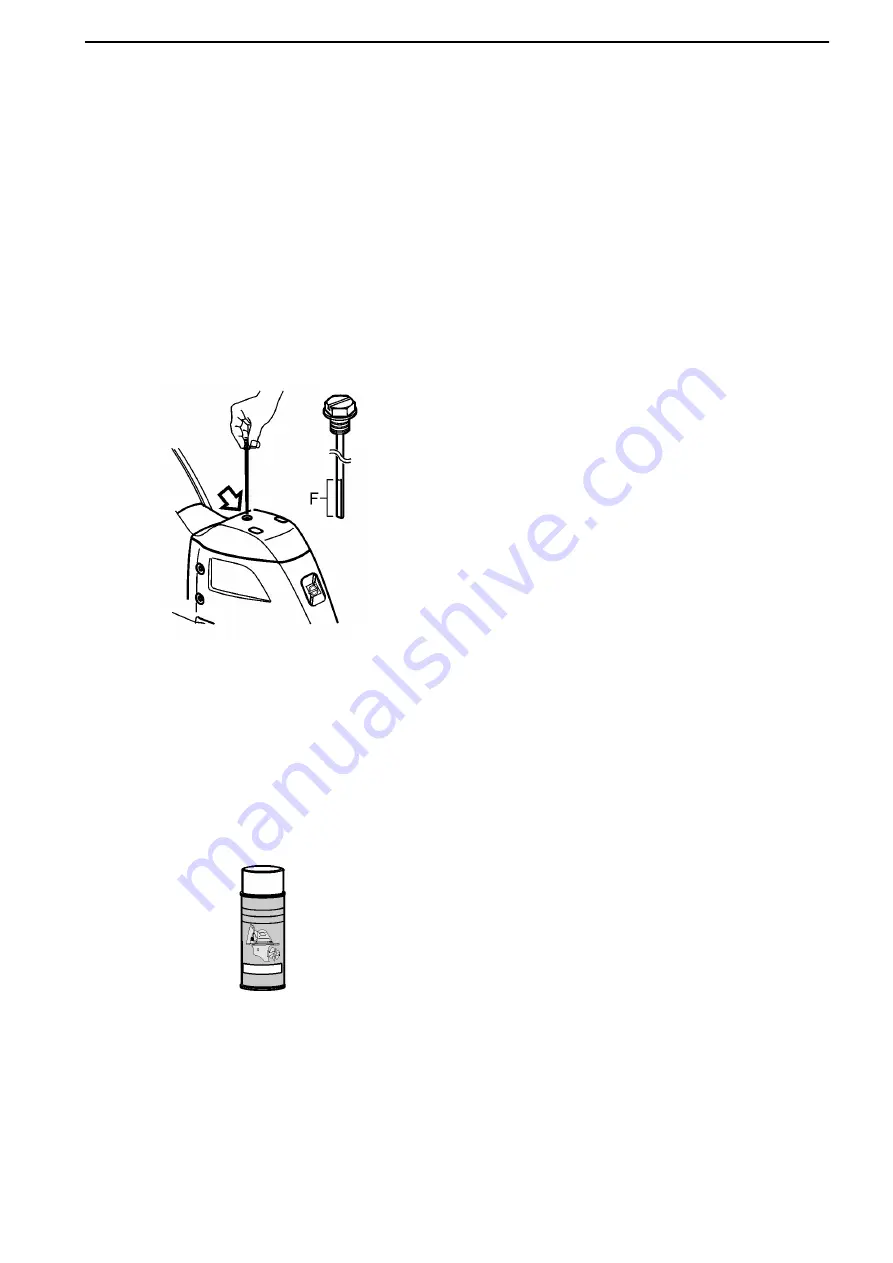

Checking the Drive Unit Lubricant

NOTICE!

Improper oil level, under- or overfilled, will

result in serious internal sterndrive damage.

Check lubricant (oil) level in sterndrive at each usage.

Oil level and condition checks are the best ways to

catch sterndrive problems before serious damage

occurs.

Remove the dipstick. Check for oil on the flat portion

F

of the dipstick.

If oil level is low, add small amounts through dipstick

opening until oil is at proper level.

If level is too high, remove until oil is at proper level.

See drive

Workshop Manual

.

Check O-ring on dipstick for wear or nicks. Replace if

needed.

Tighten dipstick to 48–72 in. lb. (5.4–8.1 Nm).

During oil level check, inspect oil for signs of water

intrusion. The oil should be amber in color. Milky look-

ing oil indicates water mixed with the oil. Also check for

metal or other debris in oil. If moisture or metal flakes

appear in the drive unit oil, take the boat to your Volvo

Penta dealer.

Painting the Drive

The sterndrive and transom shield require a unique

paint repair procedure. Refer to the

Workshop Man-

ual

or see your Volvo Penta dealer for additional infor-

mation regarding painting the drive.

Anti-fouling Paint: Drive and Transom

Shield

When using anti-fouling paint on the drive or transom

shield, be sure to observe the following:

50398

P0016597

Maintenance

47706041 07-2014 © AB VOLVO PENTA

87

Summary of Contents for V6-200

Page 1: ...OPERATOR S MANUAL V6 200 V6 225 ...

Page 110: ......

Page 113: ......

Page 114: ...VPA 47706155 English 01 2015 VPA 47706041 English 07 2014 ...