Group

28

Ignition

systems

Des

ig

n

and

funct

ion - General

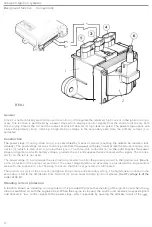

Fig. 1

'Ho

t'

Fig. 2 'Cold'

•

Spark plugs

: Use of

the

correct

type

of spark

correctly

ins

ta

lled

and

replaced

at

th

e

re

commen

d

ed in

tervals

,

is

essential to

t

he satisfactory operation of

the

system.

Assuming the

engine to be in good co

ndition

,

ad

-

herence to these recommendations

ensure maximum

plug

life, making

the

component one o

f

the most re-

liable

the

ignition

sys

tem

.

In this

context,

may be of in

t

erest to

consi

der

some of

the

demands

impose

d

on

the

spark

plugs

and

to discuss a

number

of concep

t

s.

As the

means used

to

igni

te the

mixture in

the

combustion chamber,

the

spar

k

plug

in

it

ia

t

es

the

co

mb

us

t

ion

pro-

cess

.

The

plugs are designed

to

supply up

to

approx. 25 sparks per second

per

cylinder

at 6000 rlmin in a

4

-c

ylinder

e

ngine

,

from

a high-tension source

which,

in

the

case of

electronic

ig

nition

systems,

often operates at

over 30 kV

.

-

Spark

plugs must

be

capable of

withstanding

t

he extremely rapid

temperature and pressure

flu

c

t

u

ation

s

which

oc-

cur

in the

combustion chamber.

During the

combustion

process,

th

e

temperature rises at

in

terval

s

t

o

a value

of

perhaps

and the pressure to approx

.

60bar

(

870

psi)

.

Almost

immediately,

during the induction

stro

ke

,

the plug

co

mes

in contact

with the

cold,

un

co

mpressed fuel

l

air mixture

,

which

is

likely t

o

be

at the same temperature as

the

outside air

.

-

To

e

nsure

operation

within th

e

correct operating

temperature

range, spark plugs

are made

wit

h

different heat rat

·

i

ng

s (o

r

ranges) for different

engine

types

. I

f

the operating temperature

is

too

low

(i.e. below about

400

Q

C),

the

plug

w

i

l

l

rapidly

become coated

with

combustion

residues

.

This type

of

fouling weakens the spark and

ca

uses the

e

n

-

gine

t

o

miss. On the other

hand, if

the

opera

ti

ng

temperature

is

t

oo hig

h

(ove

r

approx

.

the

fuellair

mixture

may

be

ignited by the

i

n

candescen

t

plug surfaces,

initiating uncontrolled

combus

t

ion.

Every engine

manufacturer

s

p

ecifies

the

app

r

opriate

heat rat

ing

on

the

basis of parameters such as s

p

ecific engi

ne

output, probable

runn

i

ng

conditions and

clima

t

ic conditions.

-

A plug

with

a

heat

rat

ing

has a grea

t

er

thermal retention

capacity

and

conducts less heat

away

from the

co

m

-

bustion

chamber.

This

type is

normally

used on low-speed engines operating at

relatively

low

com

bustion tem

-

peratures. Plugs

of

type

are also

known

as 'hot' plugs and are provid

ed

with a

long insula

tor

nose as shown in

Fig

.

1

.

-

A

spark

a low heat rating has

a

lower

thermal

retention capacity and conduc

ts

a grea

t

e

r amount

o

f heat

away from

the

combus

t

ion chamber. This type

normally

used

on eng

in

es

with

high specific

outpu

t

s

operating at

re

la

t

ively

high

combustion

temperatures

.

Plugs

of

thi

s

typ

e a

re

also

kn

own

as

'co

ld'

plugs

and feature

a

short

in

·

sula

t

or

nose as

shown in

Fig

.

2.

-

Fitting

a

plug with the

recommended heat rating

will

ensure

that the

correct

working temperature

is

reached

quick

-

ly w

i

thout

t

he

of overhea

t

ing.

This

also assumes

that the

t

igh

t

ening

torque

within the

speci

fied limit

s,

since

the thermal

conductivity

will

be

dependent

on

th

e degree of contact be

tw

een

the

head

and plug

.

The

spark gap should also be checked; an

excessive

gap

will

cause

the

engi

n

e

to miss.

12