71

If anything happens

–

Before jacking up - empty the bus from passengers.

–

Apply the handbrake

unless repairing a puncture in

the rear wheel.

–

Never

crawl under the bus when it is raised on the

jack only. Block up the bus with approved blocks.

–

Block up in front and behind the wheels remaining on

the ground.

–

Lifting and blocking devices should stand on a firm

and level surface.

–

Always retighten wheel nuts after approx. 200 km.

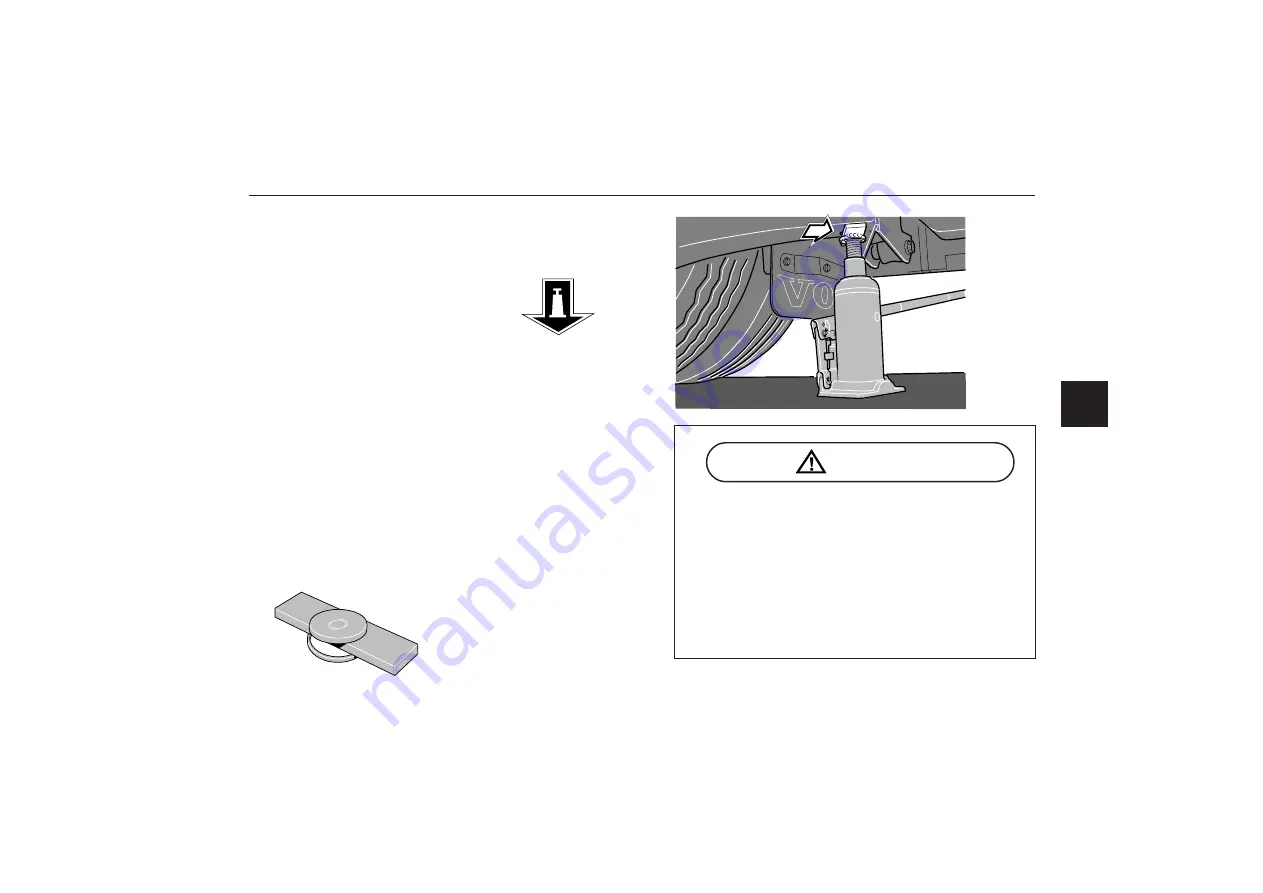

B Rear wheel puncture:

6. Make sure steps 1–5 have been carried out. (See previ-

ous page.)

7. Use the rear hole in the air suspension

member together with the adapter for

the jack. This label on the side of the

body marks the place. Remove the plas-

tic protective plug from the hole!

Make

sure the jack is vertically below the

jacking point and that the adapter is engaged in the

hole.

Screw up the jack as necessary.

8. Lift the bus high enough for the wheel to go free from the

ground.

9. Remove the wheel nuts and lift off the wheel/wheels.

10. Clean the mating surfaces and lift on the spare wheel.

11. Screw on the wheel nuts. Lower the bus so that the wheel

can not rotate and tighten the nuts according to the tight-

ening diagram overleaf. Tighten a first stage to a torque of

300 Nm and then in a second stage to 625 Nm.

12. Remove the jack and replace the plastic plug.

13. Fit the rim cover where applicable. Retrieve the warning

triangles.

14. The wheel nuts

must

be retightened after 200 km.

To prevent the jack from sliding,

this adapter (part no. 3178753)

must be engaged in the hole on

the air suspension member.

Supplied in toolkit.

Read more about changing wheels overleaf!

Warning!

Summary of Contents for B10M

Page 1: ...Driver s Manual...

Page 6: ...4 Pay attention to warning and indicator lights Their purpose is to warn of danger...

Page 131: ...129 TechnicalData Type plates 130 Specifications Data 132...

Page 142: ...140 Notes...

Page 143: ...141 Notes...

Page 144: ...142 Notes...

Page 145: ...143 Notes...

Page 146: ...144 Notes...

Page 147: ...3 Notes...