Figure 22

Brake piston, removal

Remove O-rings (35 and 39) from piston (12).

NOTE!

Do not reuse O-rings (35) (39) after removal.

12. Removal of rotary group.

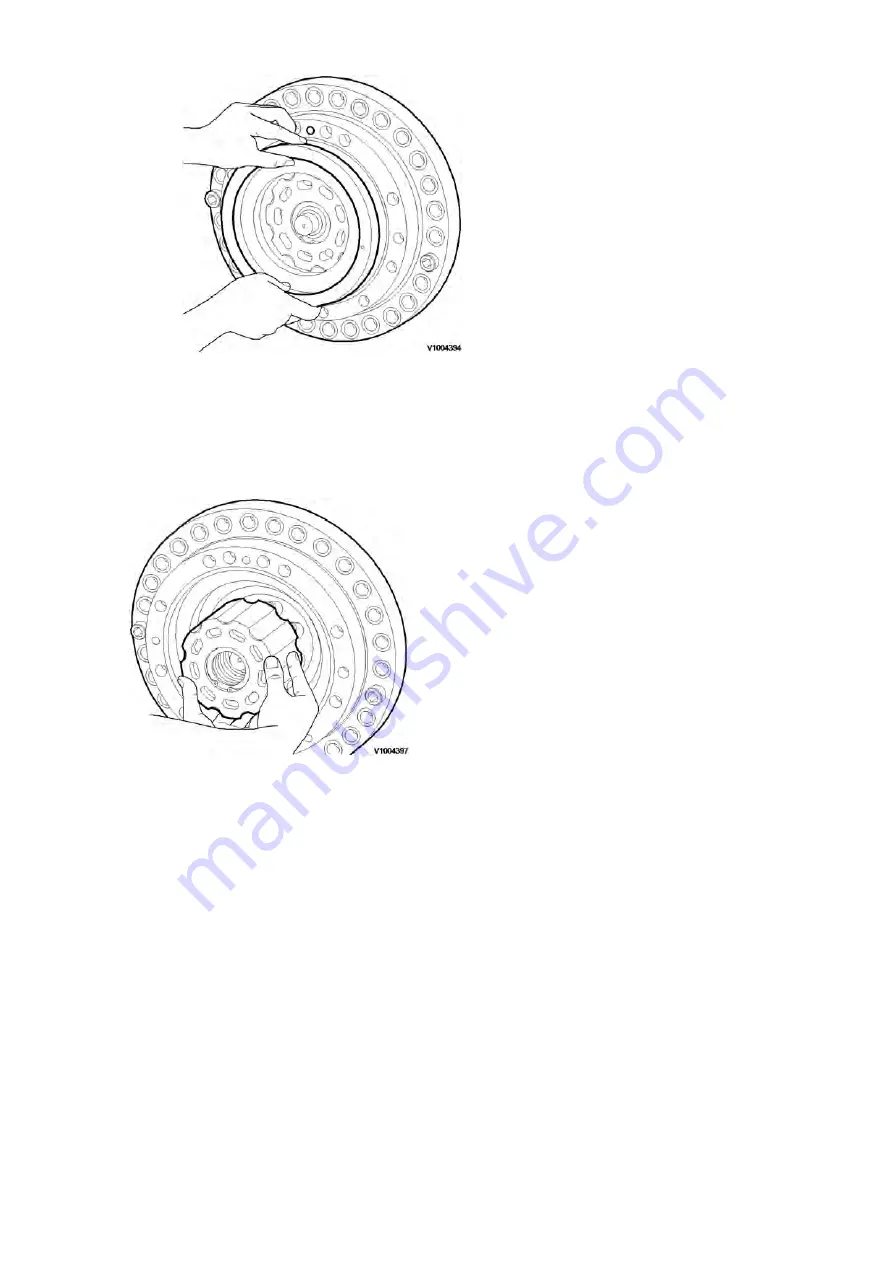

Figure 23

Cylinder block, removal

Place an oil pan under spindle (302).

NOTE!

Pistons must be installed into the same bores because of wear pattern. Mark the pistons and respective

cylinder bores.

NOTE!

Before removal, hold cylinder block (4) with both hands and turn it two to three times in a clockwise and

counterclockwise direction alternately, to detach shoes (6) from swash plate (3).

NOTE!

Be careful when removing the cylinder block that the pistons and needle rollers (51) do not fall into the

spindle.

Hold cylinder block (4) with both hands, and remove it from spindle (302).

Remove swash plate (3), steel balls (67) from spindle (302).

Remove the mating plates (16) and friction plates (15) that are mounted on the outer surface of cylinder

block (4).

Remove the piston assembly (5), shoe (6)], retainer plate (7), thrust ball (8), and needle rollers (51) from

cylinder block (4).

Summary of Contents for EC210B LC

Page 14: ...Figure 32 Spring removal ...