Group 72

Service Procedures

7116-03-02-03

Bogie Anchorage Assembly, Replacement

Please read “Guidelines for Working on the Volvo T-Ride

Suspension” page 19 before beginning this procedure.

1

Park the vehicle on a level surface and chock the front

wheels.

2

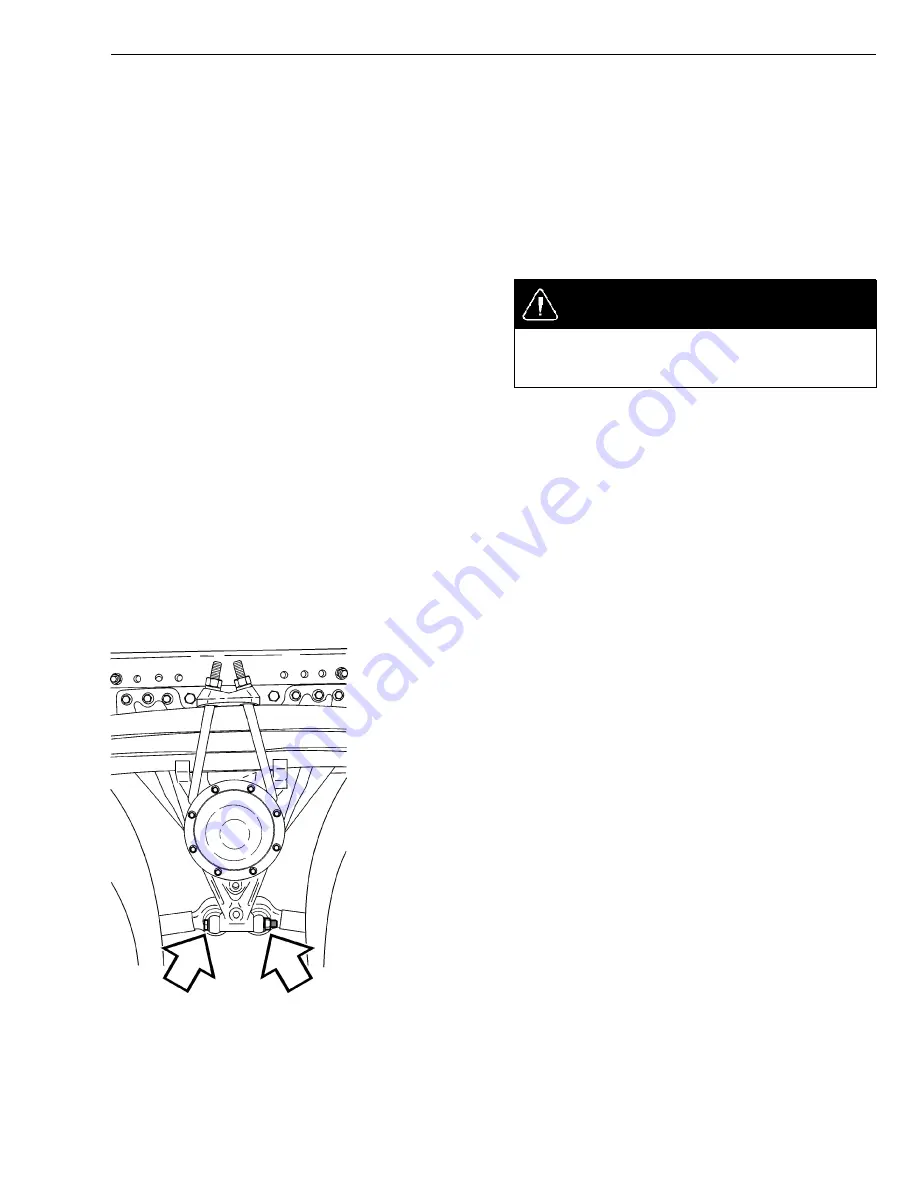

DANGER

Failure to support the nose of the axle may result in the

axle falling, which can cause serious injury or death to

anyone near or under the vehicle.

Support the nose of the axle or axles being worked on

with a bottle jack.

3

Please refer to “Spring Assembly, Rear Leaf, Removal

and Installation” page 30 for removing the Leaf Spring

Assembly.

4

Please refer to “Cradle, Replacement” page 41 for

removing the Cradle Assembly.

5

W6001355

Remove the (2) bolts and nuts that connect the lower

torque rods to the saddle bracket.

Note: It may be necessary to loosen the opposite

sides of the saddle bracket to enable easier removal or

installation, as well as proper wheel alignment during

installation of the saddle bracket.

25

Summary of Contents for Group 655-601

Page 1: ...Service Manual Trucks Group 655 601 Rear Suspension T Ride VN VHD PV776 TSP142921 ...

Page 2: ......

Page 4: ......

Page 6: ...2 ...

Page 8: ...4 ...

Page 12: ...8 ...

Page 19: ...Group 72 Design and Function W6001328 Bogie Bracket and Cradle Assembly 15 ...

Page 22: ...18 ...

Page 53: ...49 ...