Maintenance

Maintenance every 100 operating hours

77

Checking the cooling system for engine

and travel hydraulics, clean if necessary

– The contamination of the cooling system depends on the place

where the engine is used.

– The risk of contamination is increased by oil and fuel residuals

on the engine. During use and under extremely dusty

conditions keep an eye on any leaks.

– Increased contamination will occur e.g. on construction sites

due to the high dust content in the air.

– Due to the differing applicational conditions the cleaning

intervals must be determined individually for each case.

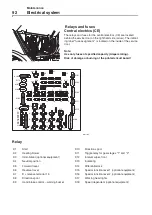

Cleaning the cooling system

– Place a dirt collecting container underneath.

– Remove the cooling air hood (1).

– Blow the engine out with compressed air, starting from the air

discharge side, pay special attention to cooling fins and oil

cooler. Remove any dirt that has been blown into the air duct.

– Do not subject sensitive engine parts, such as generator,

wiring, electronic components to the direct water jet.

– Reassemble the cooling air hood (1).

– Drive the engine warm

to evaporate any water residuals.

Cooling system for travel hydraulics (2)

– Clean cooling fan, guard grid and air guide plates.

ATTENTION!

Perform cleaning work only after the engine has stopped

and cooled down!

M200184A

1

M200068A

2

Summary of Contents for L20B

Page 1: ...OPERATOR S MANUAL Ref No VOE21A1000083 English CST Printed in Sweden ...

Page 26: ...Safety 24 Transport ...

Page 40: ...Indicators and control elements 38 Levers and switches ...

Page 48: ...Travel 46 Starting the engine ...

Page 90: ...Maintenance 88 Maintenance every 1500 operating hours ...

Page 110: ...Alphabetic register 108 Ref No VOE21A1000083 English CST Volvo Konz Printed in Sweden ...