Information

Information

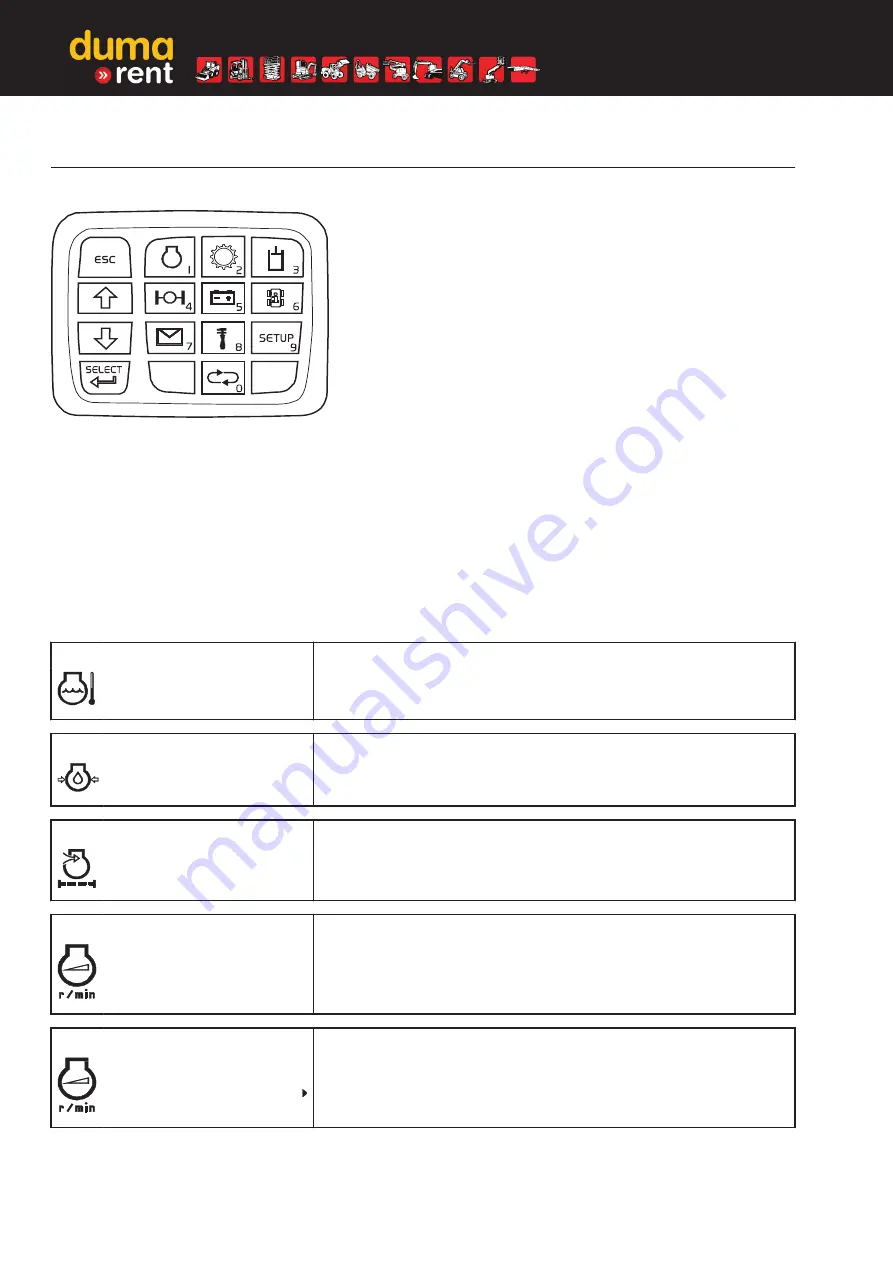

Information about the machine's status is obtained

by pressing the relevant key (0–9) on the keypad.

For each key, a number of menus and submenus

are available. Settings can be made in the

submenus.

To scroll between the menus, press arrow down or

press arrow down or

arrow up on the keypad.

arrow up on the keypad.

Settings can be made when there is an arrow

pointing to the right. Press the SELECT key to enter

a submenu.

To go back, press the ESC-key.

ENGINE

ENGINE

Coolant temperature

Coolant temperature

Shows the coolant temperature.

V1155467

XX °C/°F

XX °C/°F

Oil pressure

Oil pressure

Shows the engine oil pressure.

V1155597

XX bar/psi

XX bar/psi

Air filter

Air filter

Shows the engine air filter status.

NOTE!

NOTE!

A text message will be shown if the air filter is clogged

V1155637

Normal

Normal

Engine rpm

Engine rpm

Shows the current engine speed.

V1155642

XXX rpm

XXX rpm

Working idle speed

Working idle speed

Shows the current setting.

Press SELECT to enter a submenu where a new setting

can be made.

V1155642

Off

Off

V1134987

1 Engine

2 Transmission

3 Hydraulic system

4 Axles

5 Electrical system

6 Machine information

7 Messages

8 Service

9 Setup

10 Cycle information

46

46

Instrument panels

Instrument panels

Display unit

Display unit

www.

duma

-rent.com

Summary of Contents for L45H 2016

Page 6: ...www duma rent com ...

Page 10: ...www duma rent com ...

Page 312: ...www duma rent com ...

Page 316: ...www duma rent com ...

Page 317: ...www duma rent com ...