WARNING

Always disconnect from the power supply

before carrying out any inspection, maintenance or cleaning.

CLEANING & MAINTENANCE

GENERAL INSPECTION

•

Keep your tool clean at all times. Dirt and dust will cause internal parts to wear quickly, and shorten the

Polisher’s service life.

•

Clean the body of your machine with a soft brush, or dry cloth.

•

Never use caustic agents to clean plastic parts. If dry cleaning is not sufficient, a mild detergent on a damp

cloth is recommended.

•

Water must never come into contact with the tool

•

Ensure the tool is thoroughly dry before using it

•

If available, use clean, dry, compressed air to blow through the ventilation holes (where applicable)

TROUBLESHOOTING

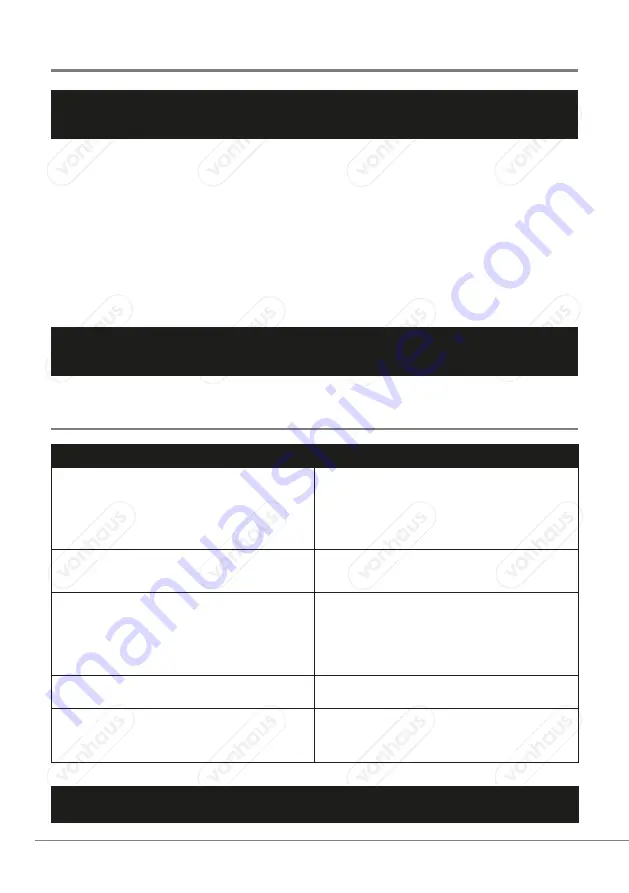

PROBLEM

SOLUTION

Ensure the tool is switched on and connected to

mains power.

Activate the

POWER SWITCH (5)

.

Check the fuse and replace if necessary.

Relieve some pressure on the polisher, do not exert

extra force. Let the polisher do the job.

If excessive noise continues, discontinue use and seek

repairs.

The material is too thick and is placing strain on the

motor.

Too much force is being exerted on the polisher, use

less force.

Allow the polisher to cool before using again.

THE TOOL WILL NOT START

THE TOOL KEEPS KICKING/STALLING

EXCESSIVE VIBRATION

EXCESSIVE NOISE

THE TOOL IS OVERHEATING

If you are having difficulty using your product and require support, please

contact

hello@domu.co.uk

NOTE

Be especially careful to clean the machine thoroughly if used for both

wood and metal. Sparks from metal work can easily ignite wood dust.

11