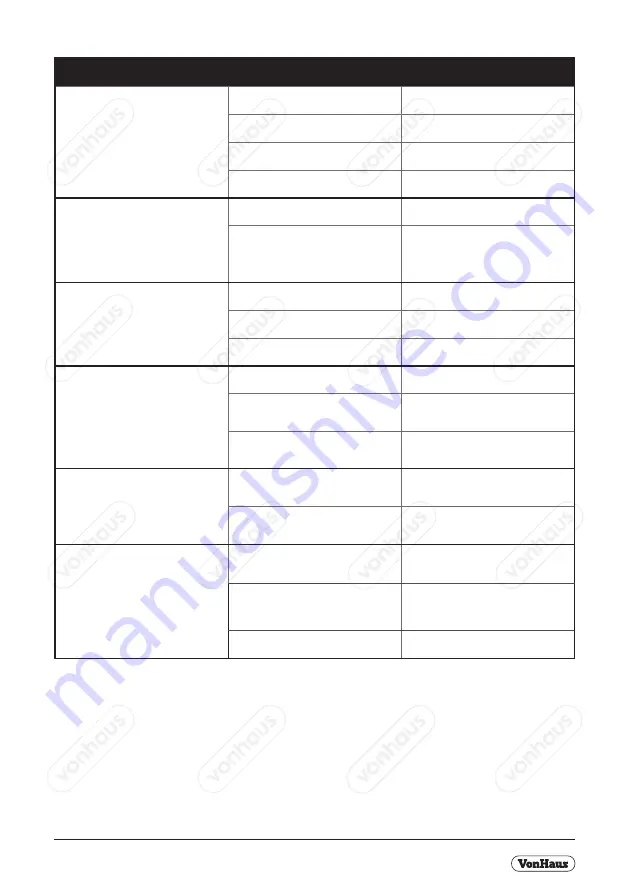

A5P | 01

PROBLEM

CAUSE

SOLUTION

Deep sanding grooves or scars in

the workpiece.

1.

Sanding belt/disc grit is too coarse

for the desired finish.

1.

Use a finer-grit sanding accessory.

2. Workpiece sanded across the

grain.

2. Sand with the grain of the wood.

3. Too much sanding force on the

workpiece.

3. Reduce pressure on workpiece

while sanding.

4. Workpiece held still against the

belt-disc for too long.

4. Keep workpiece moving while

sanding on the sanding accessory.

Sanding surface clogs quickly.

1.

Too much pressure against belt/

disc.

1. Reduce pressure on workpiece

while sanding.

2. Sanding softwood.

2.

Use different stock, different

sanding accessories, If you are

certain of using softwood this will

occur frequently. Plan on cleaning or

replacing belts/discs frequently.

Burns on workpiece.

1. Using a sanding grit that is too

fine.

1. Use a coarser-grit sanding

accessory.

2. Using too much pressure.

2. Reduce pressure on workpiece

while sanding.

3. Work held still for too long.

3. Do not keep workpiece in one

place for too long.

Motor will not start - Fuses

or circuit breakers tripping or

blowing.

1. Short circuit in line, cord or plug.

1. Inspect cord or plug for damaged

insulation and shorted wires.

2. Short circuit in motor or loose

connections.

2. Inspect all connections on motor

for loose or shorted terminals and/or

worn insulation.

3. Incorrect fuses or circuit breakers

in power line.

3. Install correct fuses or circuit

breakers or switch tool to an appro-

priately sized circuit.

Motor overheats.

1. Motor overloaded.

1. Reduce load on motor (pressure on

object being sanded).

2. Extension cord too long and of

insufficient gauge

2. Utilize an extension cord of appro-

priate gauge and length or plug tool

directly into outlet.

Motor stalls (resulting in blown

fuses or tripped circuit)

1. Low voltage.

1. Correct low voltage conditions (for

example: improper extension cord

length and/or gauge).

2. Incorrect fuses or circuit breakers

in power line.

2. Install correct fuses or circuit

breakers or plug tool into an

appropriate circuit, matched to an

appropriate fuse or breaker.

3. Excessive sanding pressure over-

loads motor.

3. Reduce the load on the motor.

Summary of Contents for 3500181

Page 5: ...A5P 01 COMPONENTS 7 8 9 4 2 1 6 10 10 5 3...

Page 6: ...A5P 01 COMPONENTS 11 13 15 17 18 19 12 14 16...

Page 8: ...A5P 01 ASSEMBLY ASSEMBL E VERSAMMLUNG MONTAJE MONTAGGIO EL MONTAJE 6 8 19...

Page 10: ...A5P 01 ASSEMBLY VACUUM OUTLET 14 11 18 18 19 2 1 2 60mm Not Supplied...

Page 11: ...A5P 01 TABLE ADJUSTMENTS...

Page 12: ...A5P 01 INSTALLING THE TABLE DISC 12 15 1 5mm Max 15 5...

Page 13: ...A5P 01 INSTALLING THE TABLE BELT 15 12 16...

Page 14: ...A5P 01 SET THE TABLE TO 90 90 90...

Page 15: ...A5P 01 MITRE GUIDE 13 13...

Page 16: ...A5P 01 OPERATION 7...