A5P | 01

EN

Please read all instructions carefully before use and retain

for future reference.

INTENDED USE

Only operate the power tool/machine

for its intended purpose and within the parameters spec-

ified in this manual.

This power tool/machine is for domestic use only. Do not

use outdoors or on wet surfaces.

This power tool/machine is not intended for use by per

-

sons with reduced physical, sensory or mental capabil-

ities, or lack of experience and knowledge, unless su-

pervised or given appropriate instruction concerning the

product’s use by a person responsible for their safety.

GENERAL PRECAUTION Do not allow to be used as a

toy. Children should be supervised to ensure they do not

play with the power tool/machine.

If the power tool/machine is not functioning properly,

has been dropped, damaged, left outdoors, or immersed

in liquid, do not use, contact DOMU Brands Customer

Services.

Do not use the power tool/machine if any parts appear to

be faulty, missing or damaged.

Ensure all parts are securely attached before use.

RISK OF PERSONAL INJURY Avoid body contact with

earthed or grounded surfaces such as pipes, radiators,

ranges and refrigerators. There is an increased risk of

electric shock if your body is earthed or grounded.

Prevent unintentional starting. Ensure the switch is in the

off position before connecting to the power source and/

or battery pack, picking up or carrying the tool. Carrying

power tools with your finger on the switch, or energising

power tools that are switched on, invites accidents.

Do not operate power tools in explosive atmospheres

such as in the presence of flammable liquids, gases or

dust. Power tools create sparks which may ignite the

dust or fumes.

Always wear eye protection. Any power tool can throw

foreign objects into your eyes and cause permanent

eye damage. Always wear safety goggles (not glasses)

that comply with ANSI safety standard Z87.1. Every day

glasses have only impact resistant lenses.

Do not expose power tools to rain or wet conditions.

Water entering the power tools will increase the risk of

electric shock.

Stay alert, watch what you are doing and use common

sense when operating a power tool/machine. Do not use

a power tool/machine while you are tired or under the

influence of drugs, alcohol or medication. A moment of

inattention while operating power tool/machine may re

-

sult in serious personal injury.

Use personal protective equipment. Always wear eye

protection. Protective equipment such as dust mask,

non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personal injuries.

Remove any adjusting key or spanner before turning the

power tool/machine on. A spanner or a key left attached

to a rotating part of the power tool/machine may result in

personal injury.

Do not overreach. Keep proper footing and balance at

all times. This enables better control of the power tool/

machine in unexpected situations.

Dress appropriately. Do not wear loose clothing or jew-

ellery.

Keep your hair, clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair can be caught

in moving parts.

If devices are provided for the connection of dust extrac-

tion and collection facilities, ensure these are connected

and properly used. Use of dust collection can reduce

dust-related hazards.

WORK AREA SAFETY Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

Do not operate power tool/machine in explosive atmos

-

pheres, such as in the presence of flammable liquids,

gases or dust.

Power tool/machine create sparks which may ignite the

dust or fumes.

Keep children and bystanders away while operating a

power tool/machine. Distractions can cause you to lose

control.

GENERAL POWER TOOL USE AND CARE Do not force

the power tool/machine. Use the correct power tool/ma

-

chine for your application. The correct power tool/ma

-

chine will do the job better and safer at the rate for which

it was designed.

Do not use the power tool/machine if the switch does not

turn it on and off. Any power tool/machine that cannot

be controlled with the switch is dangerous and must be

repaired.

Disconnect the plug from the power source and/or the

battery pack from the power tool/machine before making

any adjustments, changing accessories, or storing pow-

er tool/machine tools. Such preventive safety measures

reduce the risk of starting the power tool/machine ac

-

cidentally.

Store idle power tool/machine out of the reach of children

and do not allow persons unfamiliar with the power tool/

machine or these instructions to operate the power tool/

machine.

Power tool/machines are dangerous in the hands of un

-

trained users.

Maintain power tool/machines. Check for misalignment

or binding of moving parts, breakage of parts and any

other condition that may affect the power tool/machines

operation. If damaged, have the power tool/machines re

-

paired before use. Many accidents are caused by poorly

maintained power tool/machines.

Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp cutting edg-

es are less likely to bind and are easier to control.

Use the power tool/machine accessories and tool bits in

accordance with these instructions, take into account the

working conditions and the work to be performed.

Use of the power tool/machine for operations different

from those intended could result in a hazardous situation.

CLEANING & MAINTENANCE Never soak or immerse

electrical components and or a component that has a

plug attached.

Disconnect the plug from the power source before mak-

ing any adjustments, changing accessories, or storing.

Such preventive safety measures reduce the risk of start-

ing the power tool accidentally.

Ensure the motor has fully stopped before cleaning,

clearing a blockage, checking, or carrying out any main-

tenance on the tool.

Maintain your power tool. Check for misalignment or

binding of moving parts, breakage of parts and any oth-

er condition that may affect the power tool’s operation.

If damaged, have the power tool repaired by a qualified

repair person before use. Many accidents are caused by

poorly maintained power tools.

Keep cutting tools sharp and clean. Properly maintained

cutting tools with sharp cutting edges are less likely to

bind and are easier to control.

Regularly check external nuts and fixings to ensure vibra

-

tion caused by normal use has not begun to loosen them.

Store idle power tools out of reach of children and do

not allow persons unfamiliar with the power tool or these

instructions to operate the Breaker.

Locate the power tool out of reach of children, in a dry,

Summary of Contents for 3500219

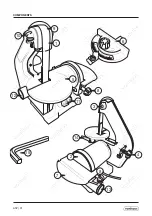

Page 5: ...A5P 01 COMPONENTS 2 14 7 3 1 9 10 4 13 5 8 15 8 6 11 12...

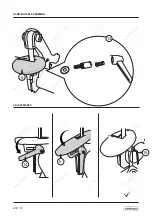

Page 7: ...A5P 01 ASSEMBLY ASSEMBL E VERSAMMLUNG MONTAJE MONTAGGIO EL MONTAJE 9 10 9...

Page 8: ...A5P 01 SANDING TABLE ASSEMBLY ADJUSTMENTS 5 14 14 5 15...

Page 9: ...A5P 01 DISC TABLE ASSEMBLY 7 8 x2...

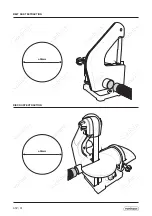

Page 10: ...A5P 01 OPERATION MITRE GUIDE ADJUSMENTS 1 6m m Max 11 6...

Page 11: ...A5P 01 BELT DUST EXTRACTION 39mm 39mm DISC DUST EXTRACTION...

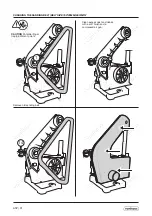

Page 12: ...A5P 01 CHANGING THE SANDING BELT BELT SIZE 760 25MM 860 MIN 1 4...

Page 14: ...A5P 01 ALIGNING THE SANDING BELT CHANGING THE SANDING BELT BELT SIZE 760 25MM 860 MIN 1...

Page 18: ...A5P 01 SANDING DISCTABLE ALIGNMENT SANDING DISC TABLE ALIGNMENT...

Page 21: ...A5P 01...