A5P | 01

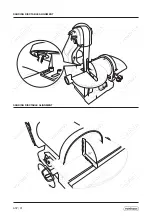

SECURING THE SANDER

WORKBENCH: If the Belt and Disc Sander is to be used

in a permanent location, it should be fastened securely

to a firm supporting surface such as a workbench.

NOTE: Mounting Bolts not supplied.

• Place the Bench and Disc Sander in the location you

require and mark the 2 holes on the base.

• Drill the holes using a 3/8” Drill Bit.

• Place the Bench and Disc Sander back into the

choosen location and align up holes.

• Using the Hex Bolts (Not Supplied) secure the Belt and

Disc Sander.

NOTE:

Bolt length should be 1.1/2” plus the

thickness of the bench top.

CLAMPING: If your Belt and Disc Sander is to be

used as a portable tool, it is recommended you fasten

it permanently to a mounting board that can easily be

clamped to a workbench or other stable surface.

The mounting board should be of sufficient size to

avoid tipping while Belt and Disc Sander is in use. Any

good grade plywood or chipboard with a 3/4 in. (19

mm) thickness is recommended.

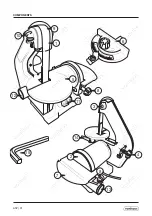

CONTENT LIST

1. 80 Grit Sanding Belt (760 *25mm) 860/min

-1

2. 80 Grit Grinding / Sanding Disc (Ø 125mm)

3. Sanding Belt Tensioning Screw

4. Sanding Belt Unlocking Screw

5. 45° Adjustable Belt Table

6. Mitre Guide

7. 45° Adjustable Disc Table

8. Disc Table Adjusment Screws

9. Safety Belt Cover

10. Safety Belt Locking Screw

11. On/Off Switch

12. Sanding Belt Dust Outlet

13. Sanding Disc Dust Outlet Cover

14. Sanding Disc Table Adjusment Lever

15. Hex Key

1 x 120 Grit (25*760mm) Sanding Belt

1 x 240 Grit (25*760mm) Sanding Belt

1x 120 Grit (Ø 125mm) Sanding Disc

1x 240 Grit (Ø 125mm) Sanding Disc

Summary of Contents for 3500219

Page 5: ...A5P 01 COMPONENTS 2 14 7 3 1 9 10 4 13 5 8 15 8 6 11 12...

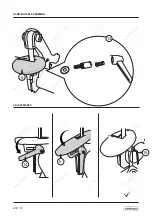

Page 7: ...A5P 01 ASSEMBLY ASSEMBL E VERSAMMLUNG MONTAJE MONTAGGIO EL MONTAJE 9 10 9...

Page 8: ...A5P 01 SANDING TABLE ASSEMBLY ADJUSTMENTS 5 14 14 5 15...

Page 9: ...A5P 01 DISC TABLE ASSEMBLY 7 8 x2...

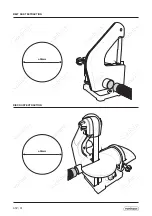

Page 10: ...A5P 01 OPERATION MITRE GUIDE ADJUSMENTS 1 6m m Max 11 6...

Page 11: ...A5P 01 BELT DUST EXTRACTION 39mm 39mm DISC DUST EXTRACTION...

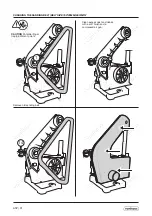

Page 12: ...A5P 01 CHANGING THE SANDING BELT BELT SIZE 760 25MM 860 MIN 1 4...

Page 14: ...A5P 01 ALIGNING THE SANDING BELT CHANGING THE SANDING BELT BELT SIZE 760 25MM 860 MIN 1...

Page 18: ...A5P 01 SANDING DISCTABLE ALIGNMENT SANDING DISC TABLE ALIGNMENT...

Page 21: ...A5P 01...