Summary of Contents for NORDIK HVLS SUPER BLADE 300/120

Page 1: ...NORDIK HVLS SUPER BLADE Instruction booklet COD 5 571 084 934 23 07 2021...

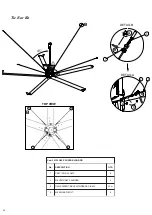

Page 23: ...23 Attachment 1 Assembly Instructions...

Page 34: ...34 Assembly rod holder and rod PLACE ROD INTO MOTOR HOLDER AND FIX WITH SCREWS NUTS AND BOLTS...

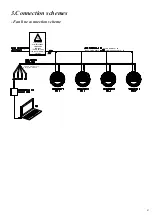

Page 52: ...52 Attachment 2 Electric connection...

Page 67: ...67 8 Connection Diagram with VORT T HCS Electric Scheme Option 3 VORT T HCS VORTICE Code 20151...

Page 70: ...70...