20

7.3

Extraordinary maintenance

Extraordinary maintenance refers to work on the electronic board, and replacing blades or other mechanical parts.

The methods are described in the assembly manual enclosed.

ALL maintenance operations, including extraordinary maintenance tasks, must be strictly done with the ma-chine

stopped and disconnected from the electricity supply, by a specialist operator trained as indicated in this manual. All

precautions must be taken to avoid anyone inadvertently powering the plant while extraordinary maintenance work is

in progress. We therefore recommend adequately indicating the fact that the power must not be switched on during

the operations, using suitable means (e.g. locking the electrical panel with a key). The specialist personnel involved

must wear specific personal protection equipment, especially working gloves, protective hard hat, and safety footwear.

For work done at a height, adequate means must be used such as a scaffold or mobile platform that can be raised.

All of these must have strong hand railings in good condition. Personnel working at a height must be equipped with

the necessary devices to prevent them falling. At the time of the work, the personnel must ensure that they are not

exposed to a risk of being struck by another ceiling fan, adjacent to the one they are working on. If this is the case,

the other machine must also be disconnected. On completion of the operations, before powering the machine again,

all the people and equipment involved in the works must be removed and take a safe distance to the side of the

blades of about 1 m, while below the machine there must be no impediment within about 2,7 m of the fan.

Maintenance records

We believe that for safe use of the product it is important that the user sets up a suitable register for routine checks

and maintenance done, in the form called for by applicable local norms. This may be based on the "Periodic Check"

table above, which may be developed graphically to form a checklist with tick boxes for the individual tasks carried

out.

We recommend that accurate records be kept of each activity and/or maintenance task and/or replacement, indicating

the operator, with adequate space for recording any anomaly or problem encountered.

We recommend that the safety instruction warning be clearly visible on the register as well: "If in doubt as to any

operation being carried out on the machine, interrupt the work, make the machine completely safe, and contact the

manufacturer to obtain the necessary technical clarifications".

8.1

Technical data

8 TECHNICAL CHARACTERISTICS

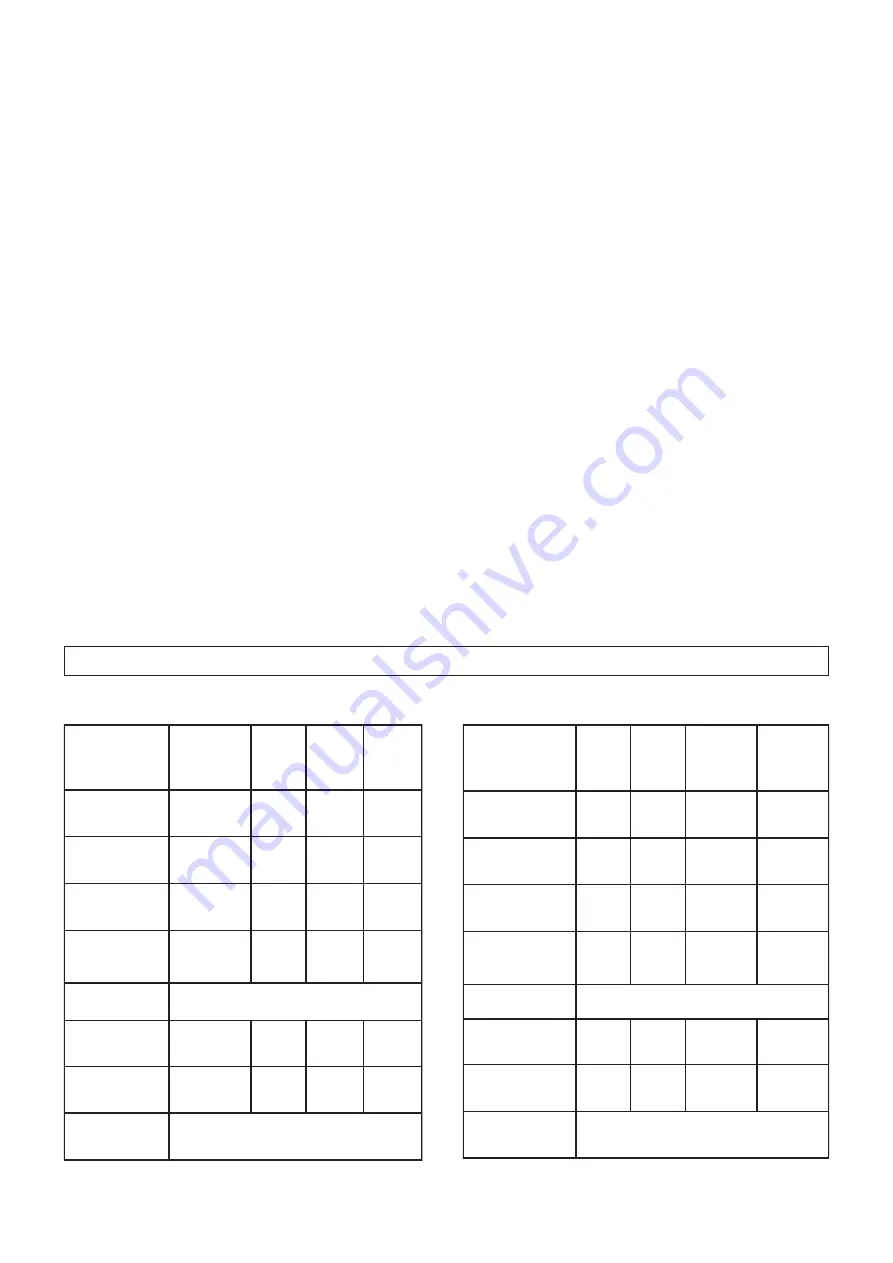

Data

NORDIK

HVLS

300/120” E

NORDIK

HVLS

400/160”

E

NORDIK

HVLS

300/120”

E L

NORDIK

HVLS

400/160”

E L

Motor weight

[kg]

20,5

20,5

20,5

20,5

Fan blade

weight

[kg]

21

29,5

21

29,5

Total weight

[kg]

70

76,5

70

76,5

Max

Consumption

[W]

725

370

725

370

Power

supply

200-480 V ~ 50-60 Hz

Absorbed

Current [A]

1,97

1,01

1,97

1,01

Maximum

speed [RPM]

150

80

150

80

Minimum

speed [RPM]

10

Data

NORDIK

HVLS

300/120”

110V

NORDIK

HVLS

400/160”

110V

NORDIK

HVLS

300/120” L

110V

NORDIK

HVLS

400/160”

L 110V

Motor weight

[kg]

20,5

20,5

20,5

20,5

Fan blade weight

[kg]

21

29,5

21

29,5

Total weight [kg]

70

76,5

70

76,5

Max

Consumption

[W]

405

280

405

280

Power

supply

85-264 ~ 50-60 Hz

Absorbed

Current [A]

1,98

2,70

1,98

2,70

Maximum speed

[RPM]

140

80

140

80

Minimum

speed [RPM]

10

Summary of Contents for Nordik HVSL Super Blade 110 V Series

Page 1: ...NORDIK HVLS SUPER BLADE E SUPER BLADE 110 V Instruction booklet COD 5 571 084 939 23 07 2021 ...

Page 25: ...25 INVERTER MOTOR ELECTRONICS QUICK CONNECTORS ...

Page 28: ...28 Destratification Fan assembly ...

Page 56: ...56 Attachment 2 Electric connection ...

Page 67: ...67 Multi wire diagram for system wiring SINGLE PHASE 85 264V 50 60 Hz ...

Page 78: ......

Page 79: ......