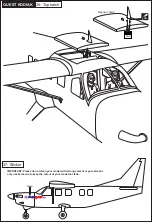

QUEST KODIAK

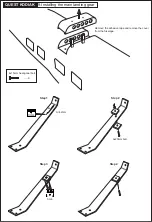

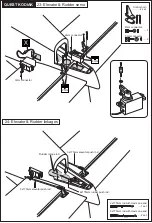

18-Installing the vertical stabilizer

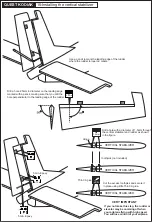

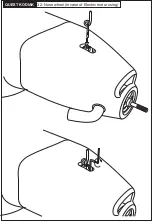

Drill a hole 2.5mm in diameter on the leading edge

marked with a pencil, making sure that you drill the

hole perpendicular to the leading edge of the rudder.

2.5mm

Use a pencil to mark the leading edge of the rudder

where the rudder torque rod meets.

5 min. Epoxy

5 min. Epoxy

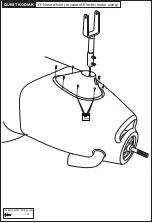

VERY IMPORTANT

If you not make this step, the rudder or

elevator may be comming off when

your airplane flying with high speed.

You will lose control of your airplane.

1.5mm

VERTICAL STABILIZER

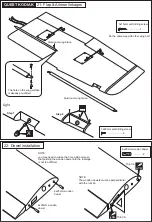

Cut the excess toothpick and secure it

in place using little Thin CA glue.

CA

Thin CA glue

Toothpick (not included)

Drill a hole with a diameter of 1.5mm through

the vertical stabilizer and rudder as shown

in the figure.

VERTICAL STABILIZER

VERTICAL STABILIZER

Hinge

Summary of Contents for KING QUEST 100

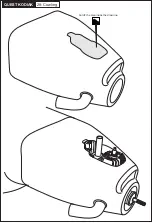

Page 23: ...Cut o the area inside the draw line QUEST KODIAK 28 Cowling...

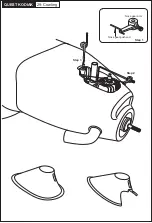

Page 24: ...QUEST KODIAK 29 Cowling Nose gear push rod Nose gear arm Step 1 Step 2 Step 3...

Page 25: ...QUEST KODIAK 30 Nose gear 2x8mm self drilling screw 9...

Page 26: ...4x40mm screw 1 4mm washer 2 4mm nut 3 QUEST KODIAK 31 Nose wheel...

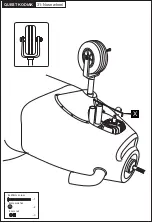

Page 27: ...QUEST KODIAK 32 Nose wheel in case of Electric motor using...

Page 28: ...QUEST KODIAK 33 Nose wheel in case of Electric motor using 2x8mm self drilling screw 12...