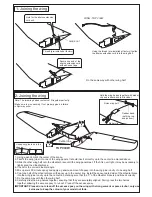

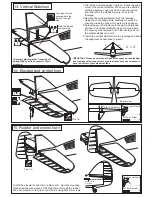

2- Joining the wing

A B

Center line

! Make sure to glue securely, If not properly glued, a failure

in flight may occur.

Use epoxy glue to bury the

opening

TOP VIEW

1- Using a pencil, mark the center of the brace.

2- Trial fit the wing joiner into one of the wing panels. It should insert smoothly up to the center line marked above.

3- Slide the other wing half onto the dihedral brace until the wing panel meet. If the fit is over tight, it may be necessary to

lightly sand the dihedral brace.

4- Check for the correct dihedral angle.

5- Mix up some 30 minute epoxy and apply a generous amount of epoxy into the wing joiner cavity of one wing half.

6- Coat one half of the dihedral brace with epoxy up to the center line. Install the epoxy-coated side of the dihedral brace

into the wing joiner cavity up to the center line, marking sure that the “V” of the dihedral brace is positioned correctly

7- Do the same way with the other wing half.

8- Carefully slide the wing halves together, ensuring that they are accurately aligned. Firmly press the two halves

together, allowing the excess epoxy to run out. Clean off the excess epoxy.

Binder clip

Nylon wing bolt

Rubber band

(both the top

and bottom)

IMPORTANT:

Please do not clean off the excess epoxy on the wing with strong solvent or pure alcohol, only use

kerosene to keep the colour of your model not fade.

Hole for the aileron extension

cord exit.

Using the thread (pre-installed at factory) to slide

the aileron extension cord into the wing half.

Thread (pre-installed at factory)

Secure one end of the

aileron extension cord

with adhesive tape

Do the same way with other wing half.

Note: The two wing halves roots must fit together perfectly.

Hold the wing halves together with binder

clip and rubber band (not include)

A B

1- Joining the wing

WING - TOP VIEW

WING ROOT