4

OPERATING INSTRUCTIONS

WARNING

To avoid personal injury and/or property dam-

age, permit only trained personnel to operate lift.

After reviewing these instructions, get familiar with lift con-

trols by running the lift through a few cycles before loading

vehicle on lift.

Observe and heed SAFETY and WARNING labels on the lift.

1. Loading: Lift must be fully lowered and no one in service

bay while the vehicle is brought on lift.

2. If lift is equipped with rolling jacks, jacks must be fully

lowered and the rear jack pushed toward center of lift to

provide under car clearance.

WARNING

Engage runway locks before raising vehicle on

jacks! DO NOT operate lift while jacks are engaged with a

vehicle!

3. Stop vehicle when it contacts the front wheel stops. At all

times, be sure rear wheels are forward of the ramp/chocks

and the ramp/chocks will clear tires when the lift is raised,

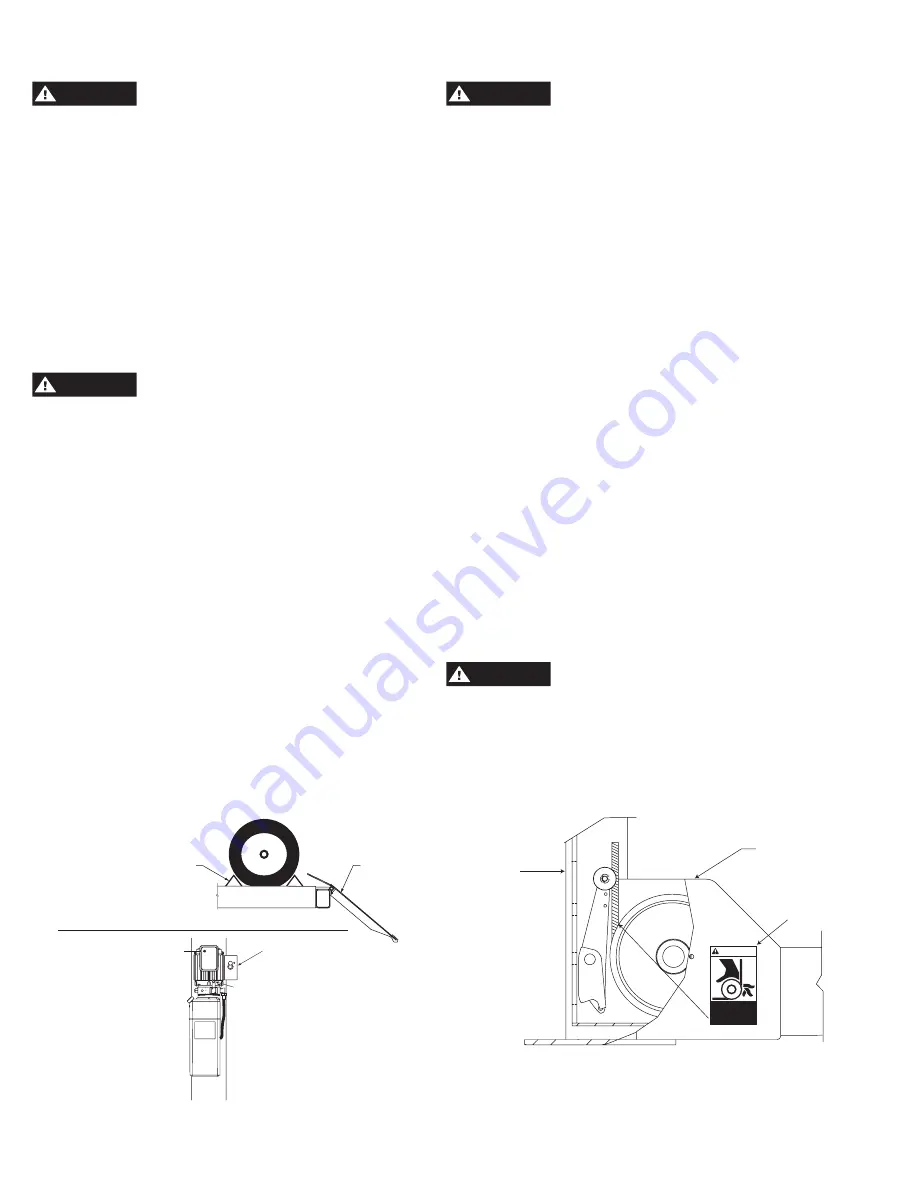

Fig. 1. Driver and passengers must exit before raising.

4. Place triangular wheel chocks on each side of one of the

rear tires, Fig. 1.

5. To Raise Lift: Push the “RAISE” button on the power unit.

Release button at desired height, Fig. 2.

6. For Rolling Jack Operating Instructions see Rolling Jack

Installation, Operation and Maintenance Instructions in the

rolling jack shipping carton.

7. Before Lowering Lift: Be sure no one is in the lift area and

that all tools, tool trays, etc. have been removed from under

the lift and vehicle.

CAUTION

Keep hands clear

of yoke ends

during lift

operation.

Fig. 2

Fig. 3

Triangular

Wheel Stops

Rear Wheel

Chock

Fig. 1

Latch Release

Air Button

LOWERING

Handle

RAISE

Button

Column

Yoke End

Hands

Clear

Warning

WARNING

The runways, ramps and connecting yokes at

each end of lift are designed to rest on the floor when fully

lowered. Observe pinch point warning decals, Fig. 3.

8. Repeat Step 2.

9. To Lower Lift: If lift has been resting on the locking latches,

lift must be raised high enough for all four latches to clear

the latch plate slots inside the columns.

10. Actuate the latch release valve on the power unit column to

disengage all four locking latches, Fig. 2. Hold actuator until

lift has fully lowered.

Note: If actuator on air valve is released, the latches will auto-

matically reset to the engaged position.

11. Push the lowering handle on the power unit to lower lift, Fig.

2. Lowering speed can be controlled by the force applied to

the lowering handle.

12. Observe lift and vehicle to be sure lift is level while being

lowered. If not, STOP repeat Steps 10 through 13.

13. Fully lower lift, remove the triangular wheel chocks and

check to be sure area is clear before removing vehicle from

lift, Fig. 1.

14. If your lift is not operating properly, DO NOT use until adjust-

ments or repairs have been made by qualified lift service

personnel.

WARNING

Keep hands clear of yoke ends while the lift is

being raised or lowered, Fig. 3.

*Maximum operation pressure is:

2500 psi (17237 kPa) for CR14

Summary of Contents for LP60032

Page 11: ...Notes...