6. Start-up preparations

Start-up of the unit at giving the ventilating system to use must be performed only by properly qualified and trained personnel of installation team. Before the unit is started

one should carefully perform some very important preparatory activities. Above all it should be checked if:

• all ventilating devices are mechanically installed and connected to the ventilating system

• hydraulic and freon system is completely mounted and prepared for working and heating or cooling medium is available during start-up

• receivers of electrical energy are wired and ready for work

• siphons and the system of drainage of condensates from draining trays are installed

• all elements of control devices are installed and wired

Moreover, the building ground should be thoroughly cleaned, devices should also be cleaned inside as well as ducting system that cooperates with them, protective foil

should be removed from protective panel of the unit. It should also be checked if some components of devices and installation, of control devices or equipment of control

devices were not damaged during installation activities.

6.1. Electric installation

Connections of electrical installation and applied protections of all receivers of electric energy should be checked if are properly connected according to given electric

diagrams of installed elements and components.

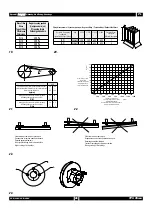

6.2. Pocket-like filters

Remove the foil protecting filters. Check the state of filters, their tightness and attachment to guide bars. Check settings of differential pressure controls (if installed), which

determine the allowable end drop of static pressure. For different types of filters these values are shown in table (fot. 20).

6.3. Water heaters

Check the state of lamellas of the heater, correctness of connection of supplying and draining pipelines. Check if the capillary tube of anti-freeze thermostat is permanently

attached to the casing of the heater. Check the setting of the anti-freeze thermostat (+4°C). Check if the regulating valve of the heater is installed in conformity with marks

placed on its casing.

6.4. Electric heaters

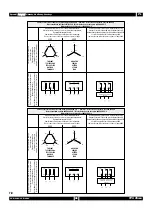

Check if little heaters of the heater are not damaged or have any contact with the elements inside the heating section. Check the correctness of electric connections

according to the wiring diagram showing the connection of electrical little heaters.

6.5. Water and freon coolers

Similarly as in case of water heaters check the state of lamellas, the quality and correctness of medium connections. Check the correctness of pipelines connections, if

the drop eliminator is set properly in relation to the direction of air flow and the correctness of siphon installation.

6.6. Cross-flow exchanger

Check the state of lamellas of exchanger (contamination, mechanical damages). Check the attachment of drop eliminator and its setting in relation to the direction of air

flow. Check the size (H dimension) and the correctness of siphon connection in units with drop eliminator placed at the pressure side of the fan.

6.7. Fan system

The fan-section needs to be checked carefully before the unit is turned on. One should check if there are any objects near the fan, which could be sucked into the impeller

after it is turned on.

It should be checked if the impeller is rotating freely, without touching the surfaces of the casing. After the electric connection is done, one should check:

• the motor connection (power voltage should correspond to the voltage on the data plate of the motor)

• the correctness of connection of ground conductor between construction elements of the fan system and the casing of the unit, in case when the fan system if equipped

with rubber shock absorbers

• the power cable present inside the fan-section is far away from all movable elements of the drive and fastened with proper holder for electrical cables.

• the direction of fan rotations – must be in conformity with the direction of the indicator arrow placed on the fan casing (turn on the fan in impulsing way). When the

direction of rotations is inverse then phases should switched in the terminal box of the motor supplied with the power of 3x400V.

Remark!

work of the unit when inspection panels are opened is allowed only for a few minutes.

After the fan and motor are checked one should check the tension of V-belts and the proper setting of wheels of belt transmission.

Inspection panels should be closed when all above checking activities are done.

CV-P/230V, CV-P/400V

39

Start-up preparations

VTS Clima

ENG