In order to achieve total heating efficiency the heater must be properly dearated. Vent plugs, placed in connecting stub pipes of the heater, are used to this purpose.

During standstill of the device the flow of heating medium should be limited to minimum so that the temperature inside the device does not exceed 60°C. Increase of the

temperature above this value can cause damage of some elements or components (motor, bearings, elements from plastic, etc.).

Electric heater

The battery of electric heater consists of not covered heating spirals. During the work of the unit, when the heater is not working dust may deposit on heating spirals. In

the moment when the heater is turned on again high contamination may cause occurring of the smell of burned dust and even fire hazard. Electric connections, technical

condition of heating elements and the level of their contamination should be controlled in equal (every 4 months) time intervals, especially before heating season starts.

Possible contamination should be removed by means of vacuum cleaning. Functioning of protection preventing from the temperature rise should be checked as well.

Water cooler

Except activities mentioned for water heaters cleanness of the drop eliminator and draining tray should be additionally controlled as well as condensates run-off and

technical condition of the siphon. Drop eliminator, if contaminated should be washed with warm water with addition of cleaning agents.

Freon cooler

Maintenance of freon cooler consists of the same activities as for water heater and cooler. When washing the freon cooler with warm water the cooling system should

be emptied sucking the freon to the container. Otherwise there is high risk of out-of-control rise of freon pressure and damage of cooling system.

Cross-flow exchanger

Maintenance of cross-flow exchanger is just checking its technical condition and the level of contamination of lamellas. Necessary cleaning should by done by vacuum

cleaning, blowing with air stream or washing the whole length of air ducts with water with addition of cleaning agents, which do not cause the corrosion of aluminium. If

the exchanger is used in temperatures below zero, the exchanger must be thoroughly dried before the unit is turned on again. In addition the condition of drop eliminator and

draining tray together with condensates draining system should be controlled. If the exchanger has the system preventing from hoarfrost deposition the correctness of system

installation should also be verified.

Fan system

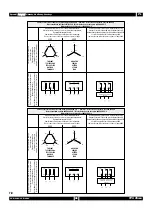

Fan and driving motor in the system are selected for optimal parameters of unit work. Rotational speed of fan in sectional units CV-P1 and CV-P2 by selection of the proper

transmission is fitted to make air stream and total fan swelling proper for cooperating ventilating system. Weaker stream of treated air means disturbances of proper working

and results in loss of balance of whole fan system. Creating too weak air stream by the fan may be caused, among other things, by sliding of driving belt.

During maintaining activities of the fan system one should check technical condition and perform the regulation of transmission belt. Originally set belt tensions should be

checked after first 50 hours of system work and after that regulations should be done at 4-months time intervals. If the tension of belts is wrong they should be tightened

moving the motor by means of tension screw placed on the lift-panel, and the values of tension should be compared with the table below. Too big tension of the belt results

in overheating and damaging of bearings and overloading of motor. Too small tension causes slide and fast wearing of the belt (fot. 21, 22).

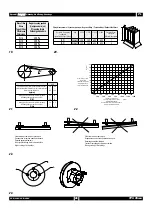

It should also be checked if the V-belt is not worn, cracked, overdried or damaged in any other way. Damaged V-belt should be replaced with a new one with the same

length and the same type as the type of grooves in belt pulley. When the belt is exchanged tension screw of the lift-panel should be loosen enough to take off the old belt

and put on the new one manually. Belts must not be put on by force and any tools must not be used for its installation. After the new belt is put on the control of the wheel

setting should be performed and using measuring tape one should check if belt pulleys are parallel and their grooves lie in the same plane. When all is set properly the drive

should be rotated without any load, so that the belt fits in the grooves of wheels. The new belt should be tighten again after 50 hours of work (fot. 23).

In order to correct concentricity of shafts of motor and fan one should set the motor properly on the tension lift-panel. In case when grooves of wheels are not situated in

the same plane one wheel (of fan or motor) should be moved along the shaft to eliminate this shortcoming. This operation is possible thanks to the pull-in-type of sleeve

‘Taper-Lock’, in which the wheel is equipped (fot. 24).

To move belt pulleys for regulation or exchange of the wheel with ‘Taper-Lock’ sleeves following activities should be performed:

• hexagonal head screws should be removed from holes marked with the letter ‘A’

• next put these screws into the hole marked with the letter ‘B’. Screws should be screwed in until the wheel and the sleeve are loosened on the shaft

• move the sleeve on the shaft neck of the motor or fan ( in case of exchange remove the sleeve together with the wheel and replace with the new set)

• place screws again in holes marked with the letter ‘A’ until the first resistance is detectable

• set belt pulleys properly

• fastening screws should be interchangeably screwed in very tightly in order to keep the sleeve and the wheel together on the shaft neck.

In case of servicing activities of the fan only, one should check if the impeller is rotating easily, if it is balanced. The lack of the balance of the impeller can be caused by

dust deposition on the blades of the impeller, detachment of additional balancing weights or damage of impeller blades.

It is recommended to check the state of bearings by hearing, putting for this purpose a screwdriver, for example, to the casing of the bearing and check what type of

sound appears. If silent sound will be audible during rotation in the form of silent buzz it means that the bearing is working properly. If, in other case, the rasp can be heard

it means that the lubrication is not enough. If sound like scrubbing or metallic noise, which repeats very often occurs it means that the bearing is damaged. In this case the

bearing should be replaced with the new one. During proper exploitation, fan bearings do not need lubrication.

When the driving motor is concerned the control of bearings should be done as described above. One should also check if the motor is installed properly and fastenings

are tight. The level of motor casing contamination should be controlled, if needed clean it without use of water. To big contamination makes difficult to cool the motor what

may result in overheating of motor windings and its damage.

CV-P/230V, CV-P/400V

41

Initial start-up

VTS Clima

ENG