39

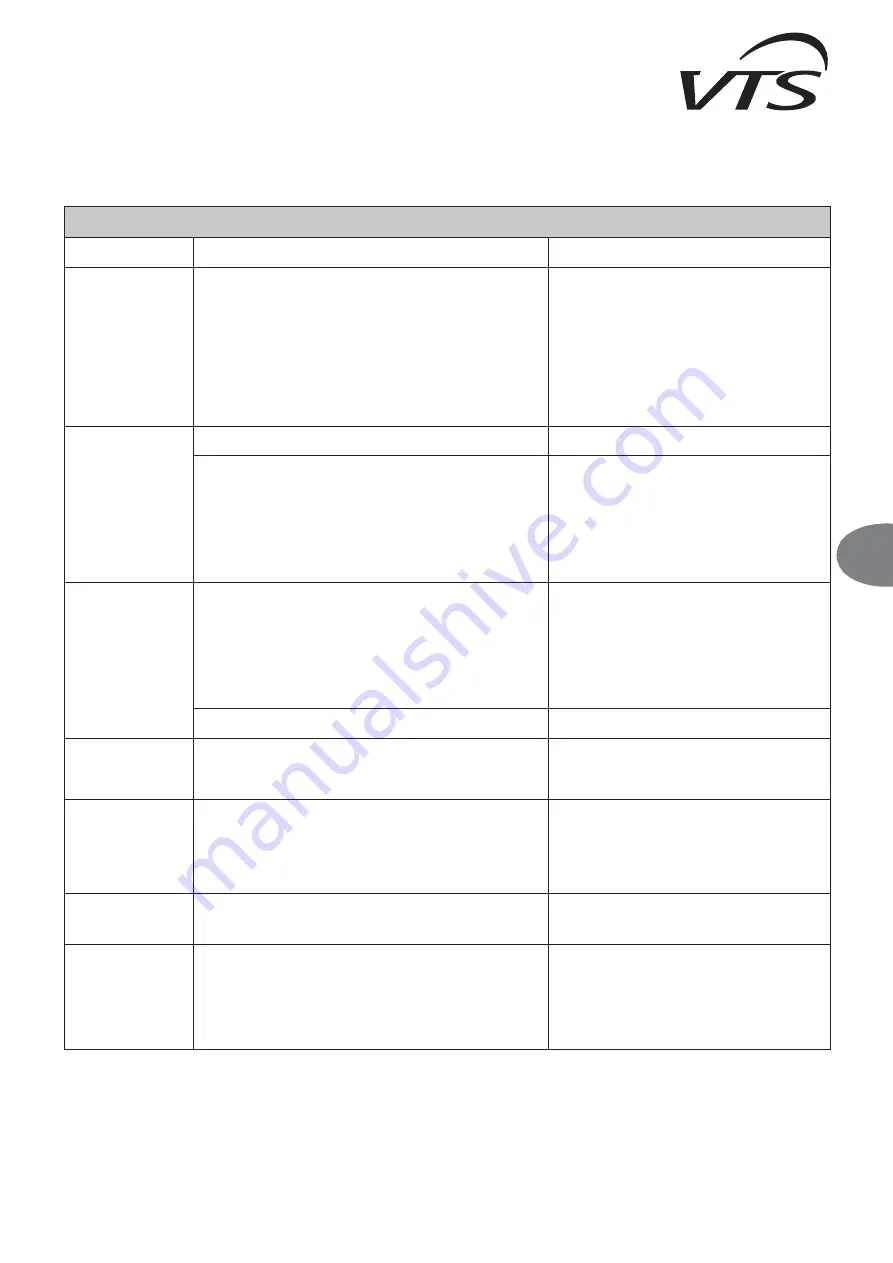

9. SERVICING

9.1 PROCEDURES IN CASE OF DEFECTS

VR Mini, VR Mini 3, VR1, VR2, VR3, VR4,

VR-D

Problem

Check points

Description

Heat exchanger leaking

● assembly of the exchanger connections with two wrenches (adjustment), which

safeguards against internal twisting of the collectors,

● Check if the leakage may be associated with mechanical damage to the

exchanger,

● Vent valve or drain plug leaking,

● Heating agent parameters (pressure and temperature) – should not exceed

permitted values,

● type of heating agent (it cannot be aggressive to Al and Cu),

● Circumstances when the leakage appears (e.g. during the first, tentative

installation start-up, when the installation is filled up after the heating agent

has been drained) and outside temperature at the time of failure (risk that the

exchanger may freeze),

● Possibility of operating in aggressive conditions (e.g. high concentration of

ammonia in the air in a sewage-treatment plant),

Pay special attention that the exchanger may freeze during winter

time. 99% of registered leakages appear during installation start-up/

pressure tests. The defect can be removed by pulling back vent or

drain valve.

Fan works too loud

● check the device assembly for conformity with the instructions in operation and

maintenance manual (e.g. distance from wall/ceiling),

min. 40 cm

● Device appropriately level led,

● Correctness of electric connections and qualifications of the wireman,

● Inlet current parameters (e.g. voltage, frequency),

● use of rotation controller different from ARW,

● noise at lower gears (possible controller failure?),

● Noise only at higher gears (regular situation explained by aerodynamic

characteristics of the device, if there outlet air chokes),

● type of other devices operating in the building (e.g. induced draught fans) –

intensified noise caused by simultaneous operation of many machines,

● Does the fan rub against the casing?

● Is the fan evenly screwed to the casing?

Level of operating noise of VOLCANO devices is perceived

subjectively. If the device is made of plastic, it should operate

quietly.It is recommended to unscrew the clamping screws and

tightening them up again. If the fault does not disappear, you should

make a complaint.

Fan does not work

● Correctness and quality of electric connections and qualifications of the wireman,

● Is there an additional bridge between required engine terminals (diagram in the

manual)

– U1 – TK (TB),

● Inlet current parameters (e.g. voltage, frequency) on the clamp block of fan

engine,

● Correctness of operation of other devices installed in the building,

● Correctness of wire connections on the engine side acc. to the manual, in

comparison to wires clamped in the engine terminal strip,

● PE conductor voltage (if present, may mean there is a break-down),

● Is N conductor correctly connected to the fan or ARW or is the connection of U2

clamps on the motor and ARW made correctly?

Electrical connection need to be done strictly according to the

drawings in the manual. If there is no bridge between U1 and

TK(TB) clamps, the motor lacks thermal protection and may break

– burn.

● damage or installation of controller different from ARW,

It is recommended to check the device/ speed controller by

connecting the heater directly to power supply.

Damaged casing

● Circumstances when it was damaged – notes on the bill of ladings, stock issue

confirmation, condition of the box,

If the casing is damaged, make photos of the box and device, and

photos confirming that the device serial number on the device

and on the box are the same. If the device was damaged during

transport, it is necessary to write down an appropriate statement by

the driver, who delivered the damaged device.

ARW

– rotation controller

does not work/ it is burned

● Correctness – quality of electric connections (wires accurately positioned

in electric clamps, cross-section and the material wires are made of) and

qualifications of the wireman,

● Only 1 controller connected to 1 device,

● Inlet current parameters (e.g. voltage, frequency),

● Correctness of VOLCANO operation after connecting “in short” (skipping ARW, i.e.

connections L and TB, N and U2, PE and PE) to the power network,

● Check if the user did not damage the knob, e.g. rotating it around

For the TRANSRATE controller, the following must also be

checked:

● circuit breaker,

● correctness of connection to the SCR10 controller,

● use of shielded conductors,

● control conductors, which should be located away from the

working conductors

Actuator does not open

the valve

● Correctness of electric connections and qualifications of the wireman,

● Correctness of the thermostat operation (characteristic tick sound during change-

over),

● Inlet current parameters (e.g. voltage),

The most important is to check whether the actuator responded

to the electric impulse within 11s. If the motor is damaged, you

need to make a complain and switch actuator operation to manual

(MAN), which mechanically opens the valve.

Programmable thermostat

does not send any signals

to the actuator/ controls

the operation of the

heating system wrongly

● Correctness of electric connections and qualifications of the wireman,

● Correctness of the thermostat operation (characteristic tick sound during switch-

over),

● Connecting a few motor of VOLCANO devices directly to the thermostat

(permitted only if contactor is used!),

● Inlet current parameters (e.g. voltage),

● Programming method exactly the same as in the manual on

● When was the last time the sensor was calibrated?

RDE thermostat is powered by batteries, that need to be replaced

(every 2 years). Also, the sensor needs to be periodically calibrated

– detailed information can be found on: www.vtsgroup.com

Complaint is unjustified, if the RDE thermostat was directly

connected to the motor, without a contactor. If the sensor incorrectly

measures the temperature, it should be calibrated (instructions in

the catalogue).

EN

Summary of Contents for VOLCANO VR Mini

Page 21: ...41...