GRA SERIES GAS FRYERS - SERVICE PROCEDURES AND ADJUSTMENTS

GAS MANIFOLD PRESSURE

ADJUSTMENT

1.

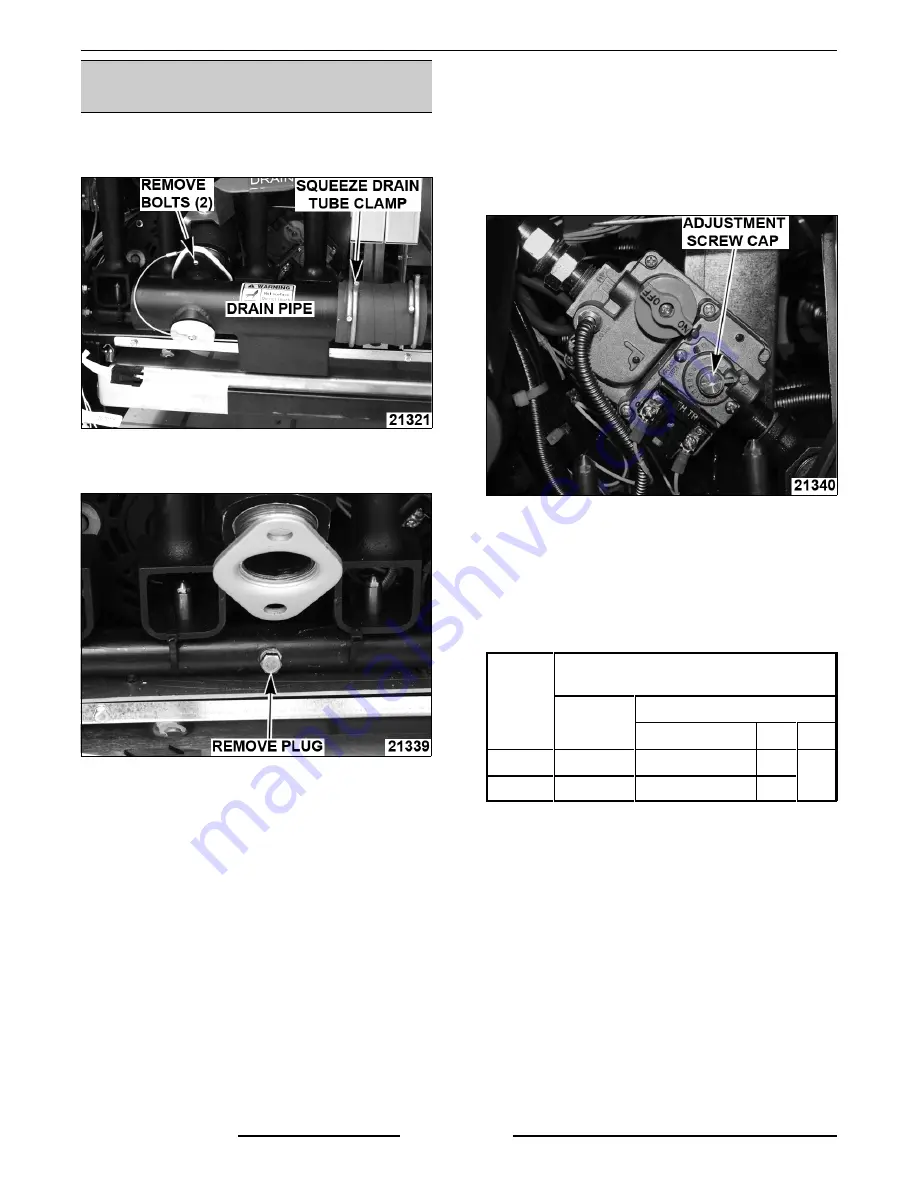

Open the door(s) and remove drain pipe.

2.

To measure the manifold pressure, remove plug

and attach manometer to pressure tap in

manifold.

NOTE:

Gas manifold pressure can also be

measured by removing the 1/8 inch NPT plug

(pressure tap) on the outlet side of the gas

combination valve and attaching a manometer.

3.

Turn the gas supply, gas combination valve and

the main power switch to on.

A.

Verify burners light.

4.

Observe the manometer pressure reading and

compare to the pressure chart near the end of

this procedure.

A.

If other appliances are connected to the

same gas line, turn them all on and check

manometer pressure reading again. If a

pressure drop of 1/2 inch water column or

more is observed, then the gas supply

needs to be checked by the gas line

installer or the local gas company for

adequate sizing.

B.

If adjustment is necessary, continue with

procedure.

5.

Remove burners as necessary.

6.

Remove the adjustment screw cap to access

the pressure adjustment screw on gas

combination valve.

A.

To increase pressure, turn the screw

clockwise. To decrease pressure, turn the

screw counterclockwise.

NOTE:

Accurate gas pressure adjustments can only

be made with the gas on and the burner lit.

7.

Set the pressure as outlined below:

GAS

TYPE

PRESSURE READINGS

(INCHES W.C.)

MANIFOLD

LINE

RECOMMENDED MIN MAX

Natural

4

7

5

14

Propane

10

11

11

NOTE:

If the incoming line pressure is less than the

minimum stated, then the manifold pressure can not

be set correctly.

8.

Once the correct pressure has been set, turn

the power switch off, replace the adjustment

screw cap and manifold plug.

9.

Install drain pipe and burners.

10. Check for proper operation.

F25377 (March 2010)

Page 18 of 36