14

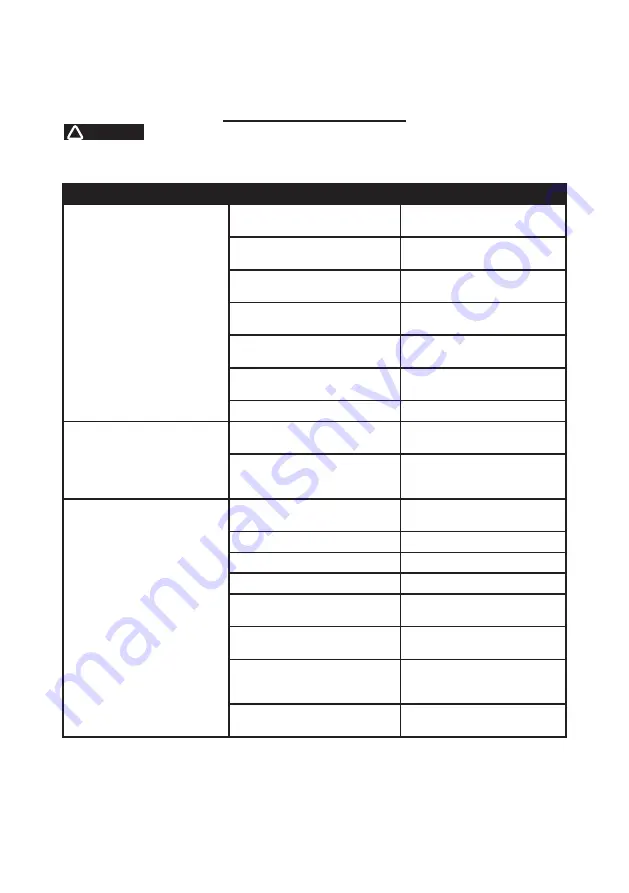

SYMPTOM

POSSIBLE CAUSE

REMEDY

Compressor runs

continuously

Petcock is open

Close petcock

Prolonged or excessive use

of air

Decrease air demand

Compressor is not large

enough for job

Check the air requirement of

air tool.

Restricted check valve

Remove and clean, or

replace

Leak in air hose or connector

Check and replace if

necessary

Tank leaks

Replace tank immediately!

Do not attempt to repair!

Blown seals

Replace

Compressor starts and stops

excessively when not in use

Petcock is partially open

Close petcock

Fittings leak

Check fittings with soapy

water. Tighten or re-seal

fittings. Do not over-tighten

Compressor will not start

Fuse or circuit breaker tripped

Check for cause & replace

or reset

Loose electrical connections

Check wiring connections

Extension cord not correct

Max. 50 ft. min. 14 ga.

Low voltage

Consult electrician

Overheated motor

Use reset button or wait for

auto reset

Check valve is stuck open

Remove and clean or

replace

Pressure bleeder valve on

pressure switch has not

unloaded head pressure

Move switch to Off and then

restart

Paint spray on internal motor

parts

Consult service centre

TROUBLESHOOTING

CAUTION

!

STOP

using the tool immediately if any of the following problems occur.

Serious

personal injury could occur. Any repairs or replacements must be done by a

qualified person or an authorized service center only.

Summary of Contents for 176-6799

Page 6: ...Nomenclature for No 176 6799 2 5 HP Air Compressor...

Page 18: ...18...

Page 19: ...19...

Page 20: ...20...

Page 21: ...21...

Page 22: ...22...

Page 23: ...23...

Page 24: ...24...

Page 25: ...25...

Page 26: ...26...

Page 27: ...27...

Page 28: ...28...

Page 29: ...29...

Page 30: ...30...

Page 31: ...31...

Page 32: ...32...

Page 38: ...38 Nomenclature pour no 176 6799 Compresseur air 2 5 HP...

Page 51: ...51 SCHEMATIC DRAWING SCH MA...