REMOVAL AND REPLACEMENT OF PARTS

CONTROL PANEL

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

The Control Panel holds the thermostats, indicator

lights and power switch.

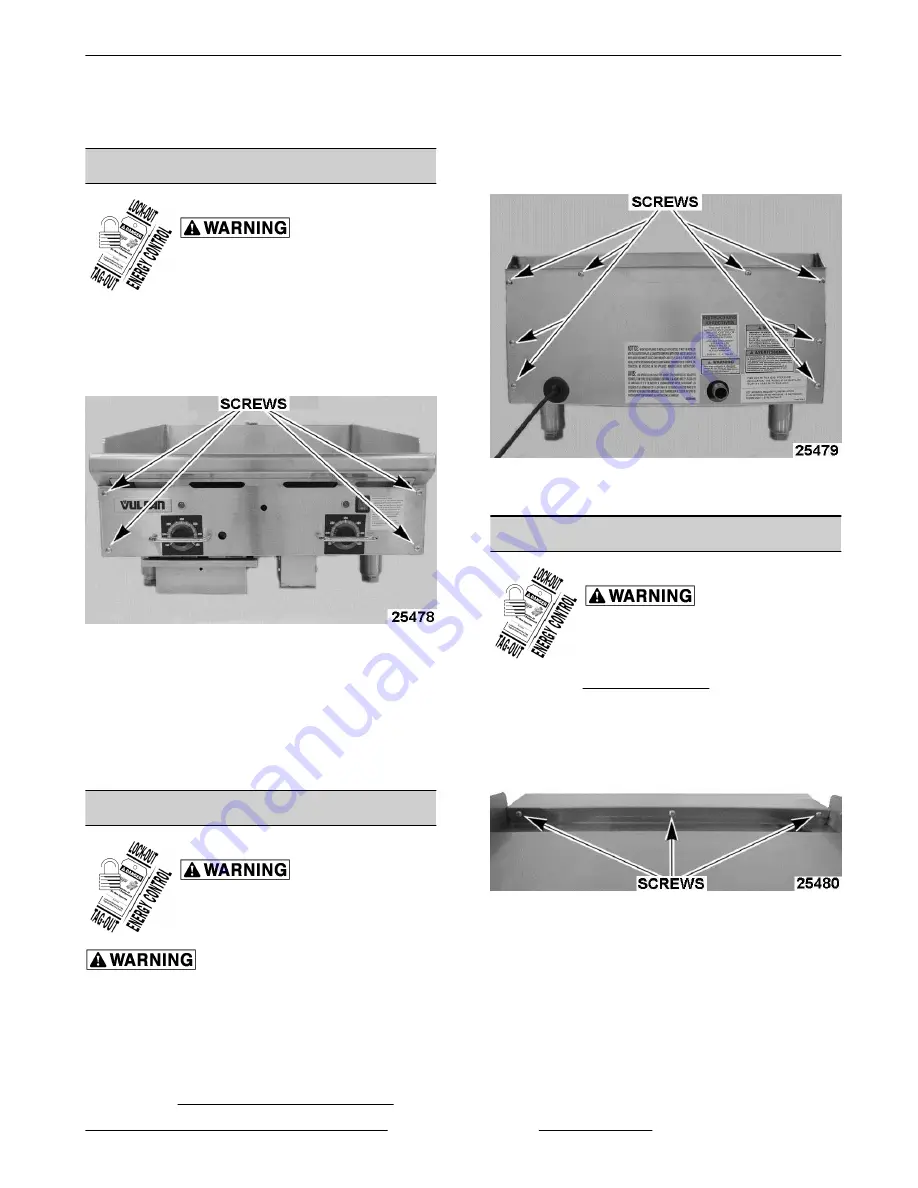

1. Remove four screws securing the front of control

panel to frame.

Fig. 1

2. Remove screw(s) that secure the bottom lip of

the control panel to the frame. The total number

of screws depend on the width of the griddle.

3. Pull control panel forward and lay face down in

front of the unit while servicing.

4. Reverse procedure to install.

BACK PANEL

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

NOTE:

Remove the back panel when changing a

burner, temperature probe or to remove excessive

grease build up from the flue area.

1. Disconnect gas supply at griddle.

2. Remove GAS PRESSURE REGULATOR.

3. Remove all screws from rear of griddle securing

the back panel.

Fig. 2

4. Reverse procedure to install.

BULL NOSE

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

1. Remove CONTROL PANEL.

2. Remove all screws securing bull nose to griddle.

The total number of screws depend on the width

of the griddle.

Fig. 3

3. Lift bull nose off griddle.

4. Reverse procedure to install.

RRG SERIES HEAVY DUTY GAS GRIDDLE - REMOVAL AND REPLACEMENT OF PARTS

Page 5 of 24

F45514 (0214)