10

MAINTENANCE

DAILY MAINTENANCE

CAUTION

!

l

Disconnect tool from air supply before cleaning and inspection.

l

Correct all problems before putting the tool back in service.

1. Wipe tool clean and inspect for wear or damage. Use non-flamable cleaning solutions to

wipe exterior of tool only if necessary.

Do Not Soak

tool with cleaning solutions. Such

solutions can damage internal parts.

2. Inspect trigger and safety mechanism to assure system is complete and functional: no

loose or missing parts, no binding or sticking parts.

3. Keep all screws tight. Loose screws can cause personal injury or damage the tool.

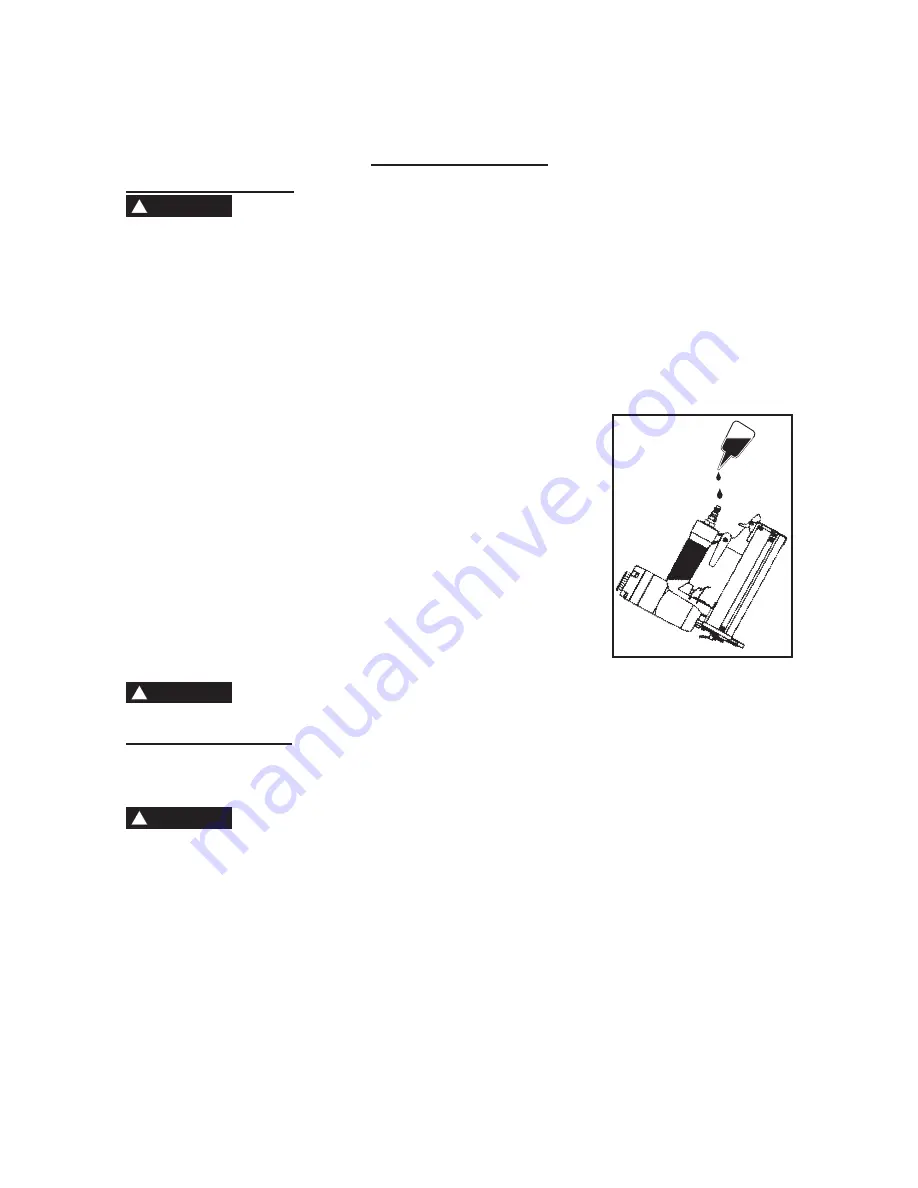

4.

If the tool is used without an in-line oiler, place 2 drops of air tool oil into the

air inlet of the tool at the beginning of each workday and after about 1 hour of

continuous use.

Frequent but not excessive lubrication is

required for best performance. Oil added through the airline

connection will lubricate all internal parts. Use only air tool oil.

Do not use oil with detergents or other additives. These can

cause damage through accelerated wear to the seals in the

tool.

5. Use a small amount of oil on all exterior moving parts and

pivots.

6. Dirt and water in the air supply are major causes of pneumatic

tool wear. See the section on SETUP: AIR SYSTEM for more

information.

7. Keep tools clean for better and safer performance. Use non-

flammable cleaning solutions sparingly and only if necessary.

Do not soak parts in the solutions.

CAUTION

!

Such solutions may damage O-rings and other parts.

TROUBLESHOOTING

STOP

using the tool immediately if any of the following problems occur. Serious personal

injury could occur. Any repairs or replacements must be done by a qualified person or an

authorized service centre only.

CAUTION

!

l

Disconnect the tool from air supply before performing any service procedure.

l

When inserting new or re-installing O-rings, make sure they are clean and lubricated with

an O-ring lubricant.

Summary of Contents for 404-7791

Page 14: ...14 SCHEMATIC DRAWING...