7

OPERATION & USE INSTRUCTIONS

WARNING

!

BE SURE THAT YOU READ, UNDERSTAND AND FOLLOW THE SAFETY

RULES THAT ACCOMPANY THIS MANUAL.

THIS WILL ALLOW FOR BEST USE AND MAXIMUM USER SATISFACTION.

SETUP & OPERATION

UNPACKING THE TOOL

Check and make sure one of each of the following are all included.

l

Combination Nailer Stapler

l

S3 hex key

l

S4 hex key

l

Small bottle of air tool oil

l

Operating instructions

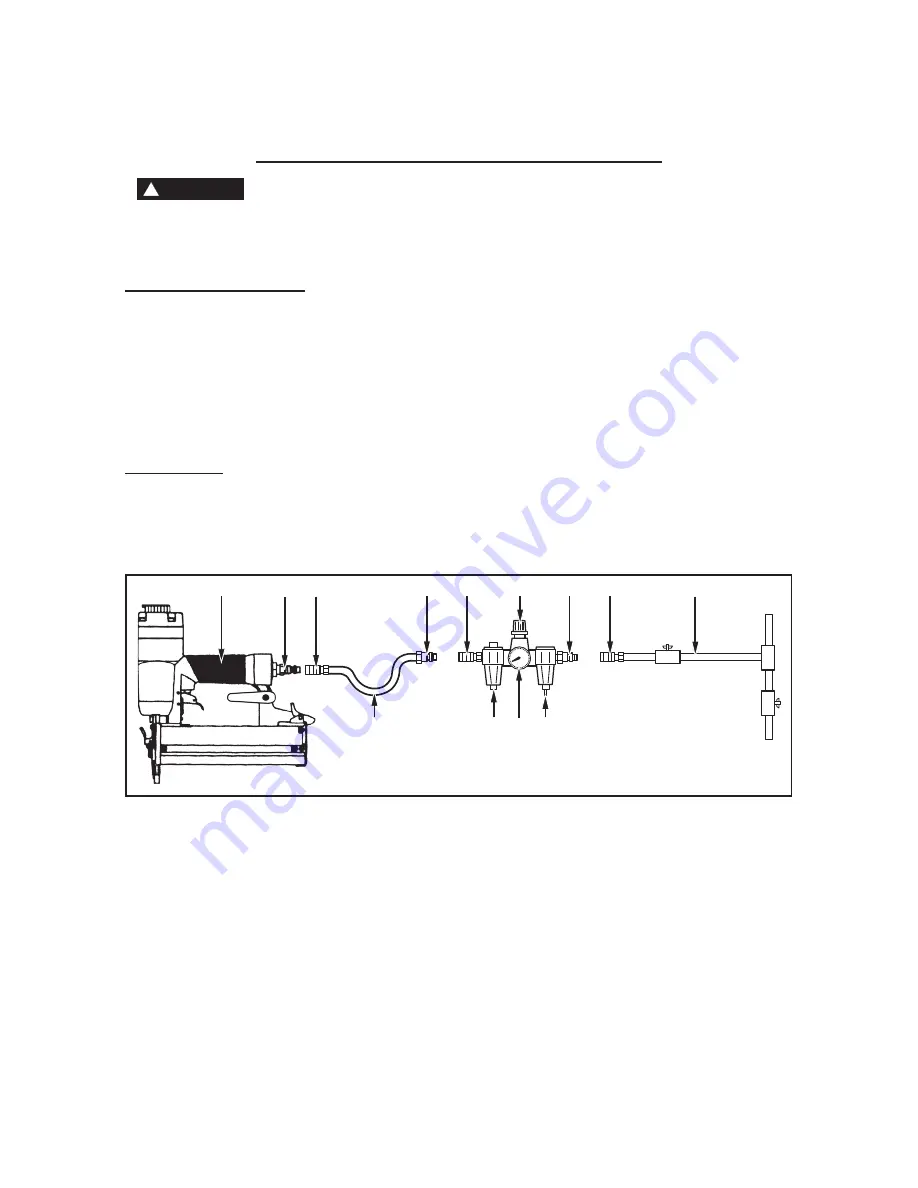

AIR SYSTEM

l

The combination brad nailer / stapler is designed to operate on clean, dry, compressed

air, regulated at 60-100 psi. The preferred system would include a filter (E), a pressure

regulator (F) with a gauge (G), and an automatic oiler (H) located downstream from the

main air supply (I), as close to the tool (A) as possible (within 15 feet is ideal). Do not use

bottled air or gases. Please see figure below:

l

All compressed air contains moisture and other contaminants that can harm the internal

components of the tool. An air line filter (E) will remove most of these and significantly

prolong the life of the tool. Ensure the in-line oiler (H) has sufficient oil. If an in-line oiler is

not available, place 2 drops of oil into the tool’s air inlet at the beginning of each workday.

More than this will be expelled from the tool’s exhaust during firing.

l

Air Fitting: The nailer (A) should be equipped with a 1/4” NPT male plug (B) to fit a ‘quick

connector’ coupling (C). To prevent accidental cycling even though disconnected, the

tool must always be connected to the air supply in such a way that all air pressure in it is

released when the coupling is disconnected.

A

B C

B

C

B

C

D

F

I

H G E

Summary of Contents for 404-7791

Page 14: ...14 SCHEMATIC DRAWING...