8

CAUTION

!

l

All air line components (including hoses, pipe, connectors, filters, & regulators, etc.) must

be rated for a minimum working pressure of 150 psi or 150% of the maximum system

pressure, whichever is greater.

l

Disconnect the tool from the air supply before loading fasteners, performing maintenance,

clearing a jammed fastener, leaving the work area, moving the tool to another location, or

handing it to another person.

LOADING THE FASTENERS

CAUTION

!

l

Keep the tool pointed away from yourself and others at all times.

l

Do not load fasteners with safety or trigger depressed.

l

Always wear approved safety glasses and hearing protection when preparing or operating

this tool.

l

Never use a tool that leaks air or needs repair.

1. Disconnect the tool from the air supply before loading fasteners.

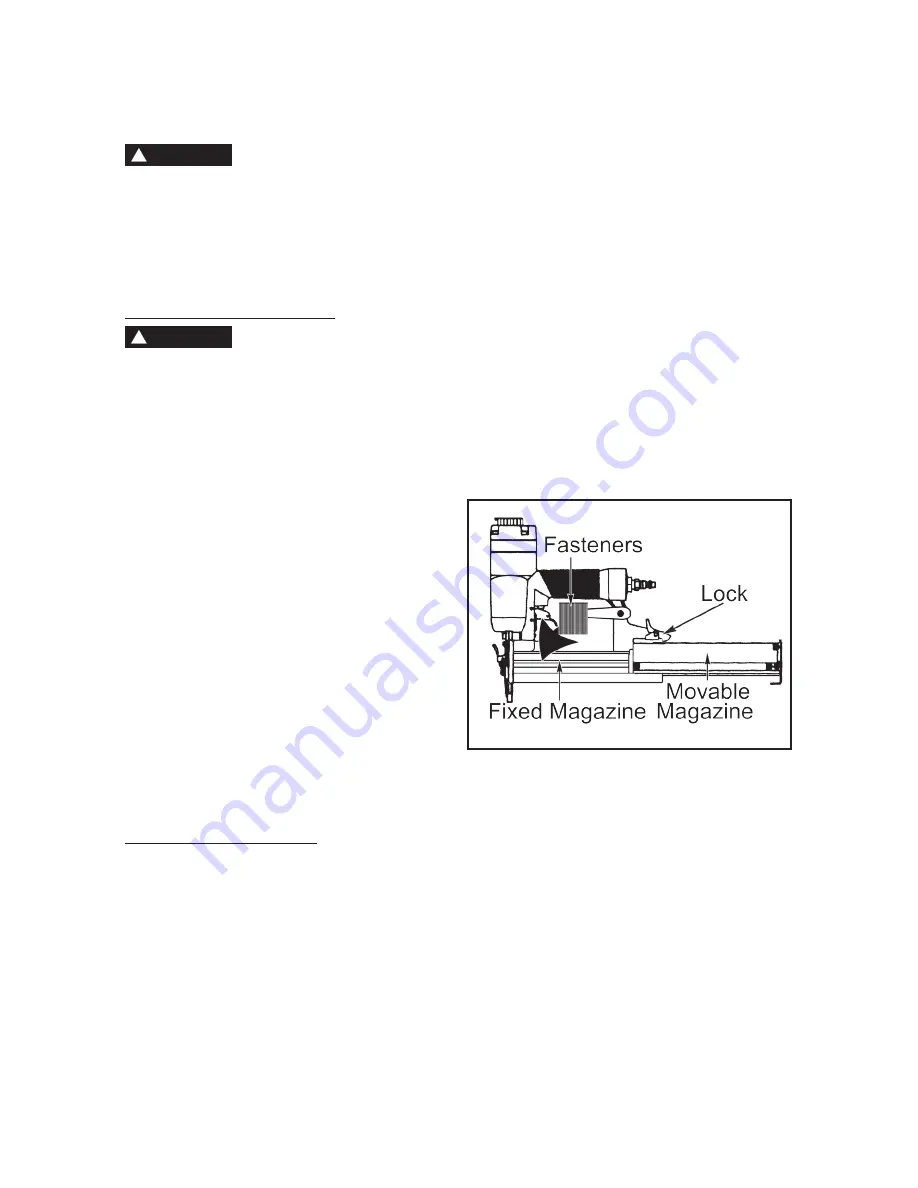

2. Depress the Lock (59) to release the

MOVABLE MAGAZINE (57) and pull the

magazine out fully as shown.

3. Being certain the gun is aimed in a safe

direction, place a full stick of the desired

type and size of fasteners on the FIXED

MAGAZINE (53). Staples should be

placed to straddle the central spine of the

FIXED MAGAZINE UNIT, and brad nails

are laid up against its left side, placed

points-down in the slot at the bottom

of the FIXED MAGAZINE. Up to 100

fasteners can be loaded in the magazine.

4. Push the MOVABLE MAGAZINE UNIT

(57) forward until the LOCK (59) clicks and secures it in place.

5. The tool is ready to operate.

CONNECTING THE TOOL

1. Be sure the tool’s lubrication needs are met.

2. Load fasteners.

3. Turn the compressor on.

4. Set the regulator to proper pressure for the size and type of fasteners being used.

5. After reading and understanding this entire manual, connect tool to air supply.

Summary of Contents for 404-7791

Page 14: ...14 SCHEMATIC DRAWING...