9

OIL

WARNING

!

This compressor requires oil of

the correct type and quantity to run. Do not

start it without first following all the steps in

this section.

1. Be sure the compressor is on a level

surface.

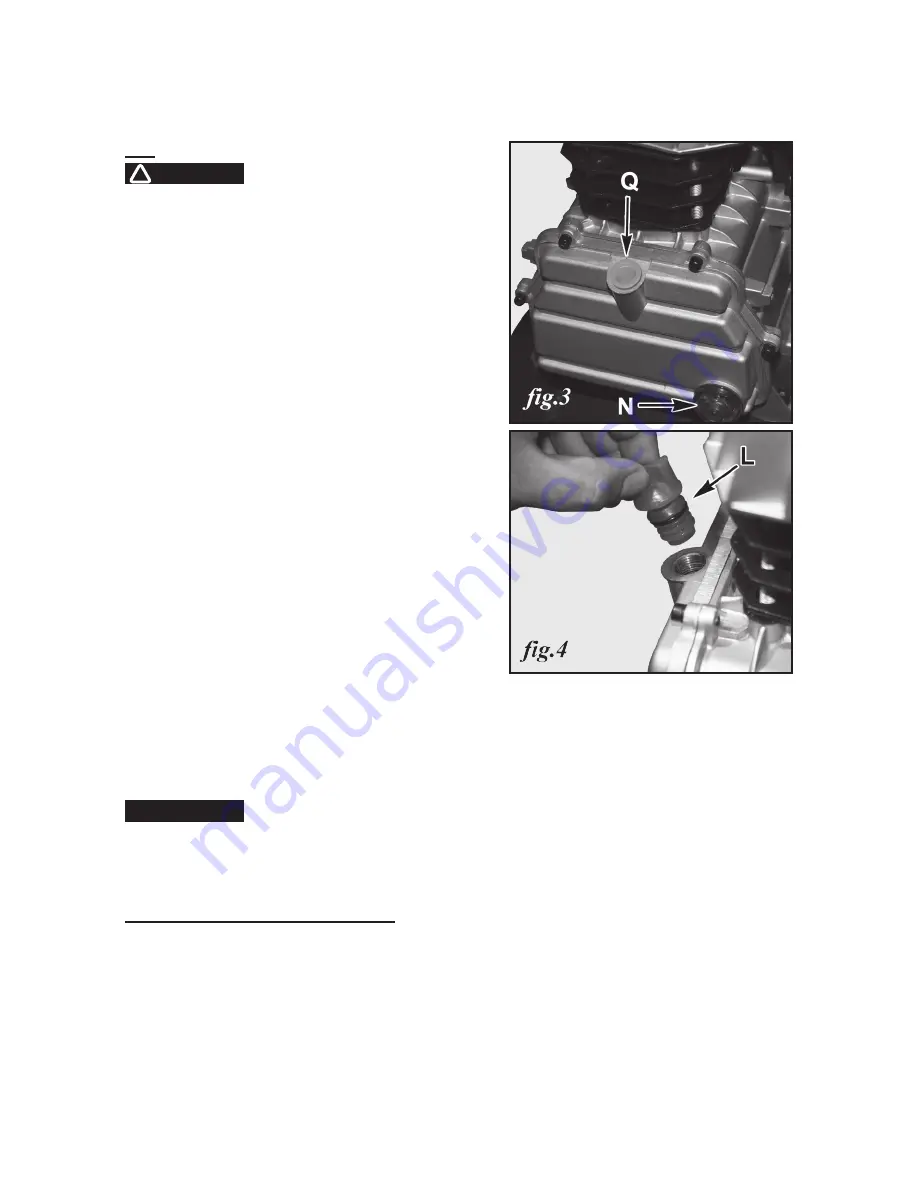

2. With the screwdriver, pry off and remove

the shipping plug from the top of the

crankcase

(

Q, fig.3

) revealing the oil fill hole.

3. Through this hole, fill the oil reservoir

with SAE-20 (API CG/CD heavy duty),

non-detergent compressor oil. In extreme

winter conditions, use lighter SAE-10

weight.

4. There may be some oil left over from the

manufacturing process already in the

reservoir.

5. Check the oil level sight glass (

N, fig.1 &

3

). The oil should show level with the red

dot in the centre of the viewing window. Be

careful not to overfill.

6. Find the oil fill plug (

L in fig.1 & 4

). It is

usually shipped separately from the

compressor and enclosed with this manual. Be sure there is a rubber O-ring on

the upper part of the threaded end.

7. Put a little pipe thread sealing tape on the threaded end of the oil fill plug.

8. Gently screw the oil breather cap into the oil fill hole. Do not cross-thread or

overtighten.

NOTE

Before installing and using this unit, inspect carefully for damage

and corrosion. Make sure the tank, compressor, motor and pump are

undamaged and that all screws and caps are securely tightened.

INSTALLATION AND LOCATION

Locate the compressor in a clean, dry and well-ventilated area; on a firm, level surface. It

should be located 12 to 18 inches from a wall or any other obstruction that would interfere with

the air flow. It is equiped with heat dissipation fins that allow for proper cooling. Keep them and

other parts free of dust or dirt that could interfere with cooling. A clean compressor runs cooler

and provides longer service. Do not place anything on top of the compressor.