10

3.

Push power switch ON and immediately touch one end of the jumper firmly to the GND terminal on the

module. Do not touch the jumper to the SPARK terminal, but, move the free end of the jumper slowly towards

the SPARK terminal until a spark is established.

Pull the jumper slowly away from the SPARK terminal and note the length of the gap when the sparking stops.

See table below for results and action to be taken.

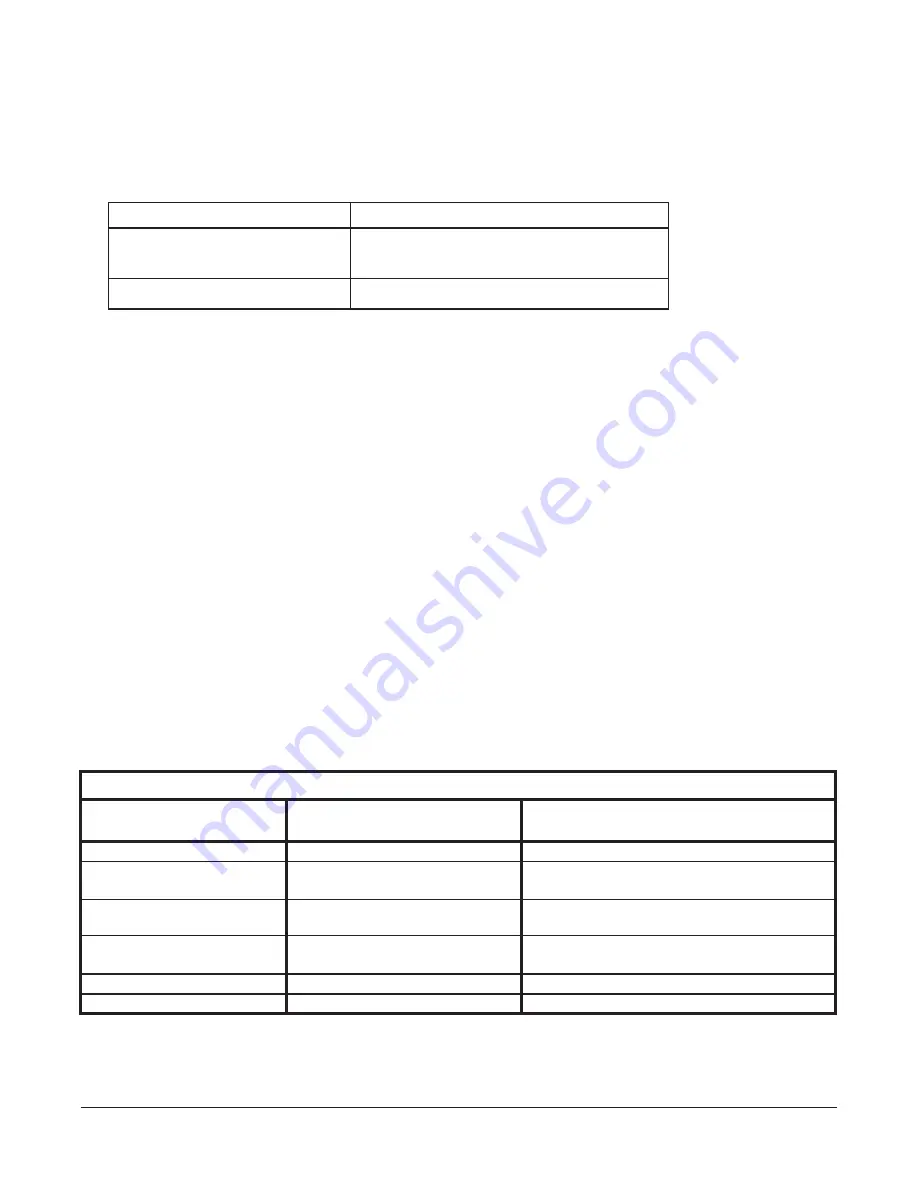

ARC LENGTH

ACTION

No arc or arc less than 1/8".

Verify power at module input terminal.

Replace module if power is verified.

Arc 1/8" or longer

Voltage output is OK.

If you are getting spark but the spark continues after the pilot is lit check the following.

4.

Check for ground wire and ignition cable continuity.

5.

Check that flame rod is clean.

6.

Check for crack in ceramic insulator again.

7.

Check that pilot flame covers rod and is steady and blue. Adjust pilot or pilot flame if necessary.

8.

If the above are all in good condition replace module.

PILOT CHECK (Pilot will not light)

1.

Check that all manual gas valves are open, that supply tubing and pressure are good and pilot orifice is not

blocked.

2.

Check electrical connections between module and pilot operator on gas combo valve.

3.

With volt meter check for 24Vac across PV-MV/PV terminals on module. If voltage is good replace the combo

valve. If voltage is bad replace the module.

BURNER CHECK (Main burner will not light)

1.

Check for 24Vac across the MV-MV/PV terminals. If voltage is bad replace the module.

2.

Check electric connection between the module and gas combo valve. If good replace the combo valve.

COMPUTER CONTROLLER DIAGNOSTIC CHECKS

The service diagnostics for the GRC Fryer computer is divided into (2) sections NORMAL and SERVICE

DIAGNOSTICS. The normal mode is the usual operating mode of the fryer. The service mode is intended to

give the service man more information regarding the nature of the system’s failure.

NORMAL OPERATING MODE CHECKS:

SYSTEM PROBLEM

DISPLAY

SYSTEM RESPONSE

OR FAILURE

Ignition

IGN. FAILURE

Heat off

Low temperature

LOW TEMP.

Heat off

lack of heat

High temperature

HIGH TEMP

Heat off

1st. limit comes on.

High temperature

CALL SERVICE

Hardware limit heat off

2nd limit comes on.

Probe

CALL SERVICE

Heat off

Self-check

CALL SERVICE

System to back up mode

Summary of Contents for GRC25

Page 61: ...61 SECTION lll WIRING INFORMATION ...

Page 62: ...62 Drwg No 419357 1 ...

Page 63: ...63 RS W MILLIVOLT SYSTEM 419999 2 ...

Page 64: ...64 Drwg No 419357 2 ...

Page 66: ...66 Drwg No 419357 3 ...

Page 68: ...68 Drwg No 419322 1 ...

Page 70: ...70 Drwg No 419322 2 ...

Page 72: ...72 Drwg No 419322 3 ...

Page 74: ...74 Drwg No 419323 1 ...

Page 76: ...76 Drwg No 419323 2 ...

Page 78: ...78 Drwg No 419323 3 ...

Page 80: ...80 Drwg No 419318 1 ...

Page 82: ...82 Drwg No 419318 2 ...

Page 84: ...84 Drwg No 419318 3 ...

Page 86: ...86 Drwg No 419340 1 ...

Page 88: ...88 Drwg No 419340 2 ...

Page 90: ...90 Drwg No 419340 3 ...

Page 92: ...92 Drwg No 419337 1 ...

Page 94: ...94 Drwg No 419337 2 ...

Page 96: ...96 Drwg No 419337 3 ...

Page 98: ...98 Drwg No 419564 1 ...

Page 100: ...100 Drwg No 419564 2 ...

Page 102: ...102 Drwg No 419564 3 ...

Page 104: ...104 Drwg No 419366 1 ...

Page 106: ...106 Drwg No 419366 2 ...

Page 108: ...108 Drwg No 419366 3 ...

Page 110: ...110 ...

Page 111: ...111 ...

Page 112: ...112 FORM 30912 1 95 ...