GAS SHUT-OFF VALVE (1SOL) -

TILTING MODELS ONLY

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

Shut off the gas before servicing the

unit and follow lockout / tagout

procedures.

All gas joints disturbed during servicing must be

checked for leaks. Check with a soap and water

solution (bubbles). Do not use an open flame.

1.

Remove CONTROL BOX COVER (TILTING).

2.

Disconnect lead wires for gas shut-off valve

(1SOL) at terminal strip in control box.

3.

Remove piping from inlet side of valve.

4.

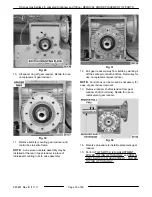

Remove threaded plug (NPT) from the ½” swivel

fitting secured to end of pivot shaft.

K20GLT Manual Tilt Shown

5.

Remove gas shut-off valve from control box.

6.

Remove piping from outlet side of valve.

7.

Reverse procedure to install replacement gas

shut-off valve and check for proper operation.

Clean pipe threads and apply thread sealant that

is suitable for use with propane gases.

GEAR REDUCER - MANUAL

TILTING MODELS

Disconnect the electrical power to

the machine and follow lockout /

tagout procedures.

Shut off the gas before servicing the

unit and follow lockout / tagout

procedures.

All gas joints disturbed during servicing must be

checked for leaks. Check with a soap and water

solution (bubbles). Do not use an open flame.

1.

Place kettle in the fully upright position and

remove crank handle.

2.

Support kettle from the bottom in some manner

(2x4 etc). Raise it slightly to take the kettle arm

weight off gear reducer.

3.

Remove GAS SHUT-OFF VALVE (1SOL) -

TILTING MODELS ONLY.

4.

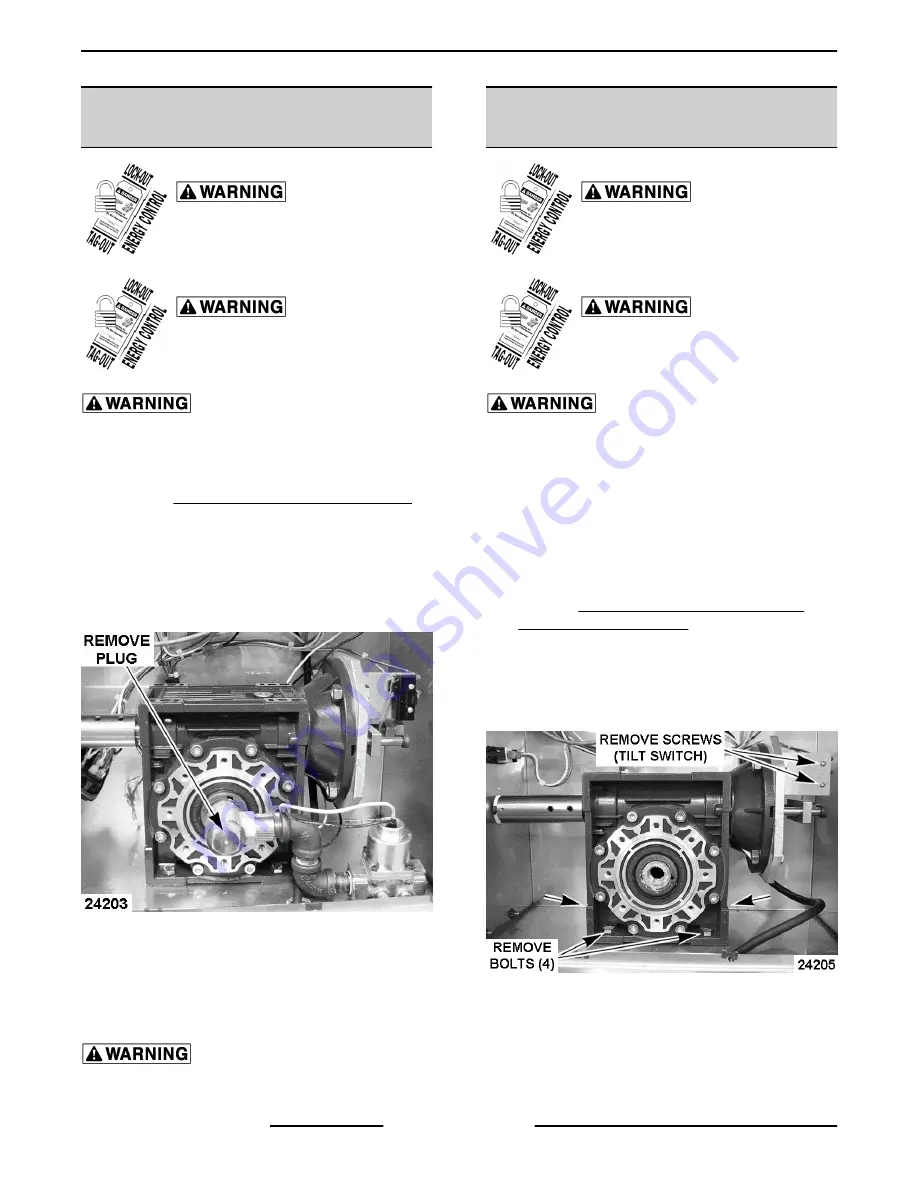

Remove tilt switch (2S) from bracket leaving the

lead wires connected.

5.

Remove bolts securing gear reducer and control

box to kettle frame.

Fig. 20

6.

Pull gear reducer away from kettle by working it

off the kettle arm until free. Note that the kettle

arm is keyed.

NOTE:

Control box can be moved as necessary for

ease of gear reducer removal.

K Series Gas Kettles 2/3 Jacketed Stationary and Tilting - REMOVAL AND REPLACEMENT OF PARTS

F45461 Rev. B (1117)

Page 14 of 48