10. Disconnect lead wire from terminal T8 on the

controller.

A.

Verify 120VAC between T8 and ground. If

correct, output from controller is functioning

properly.

B.

If incorrect, install a replacement

temperature controller and check for proper

operation.

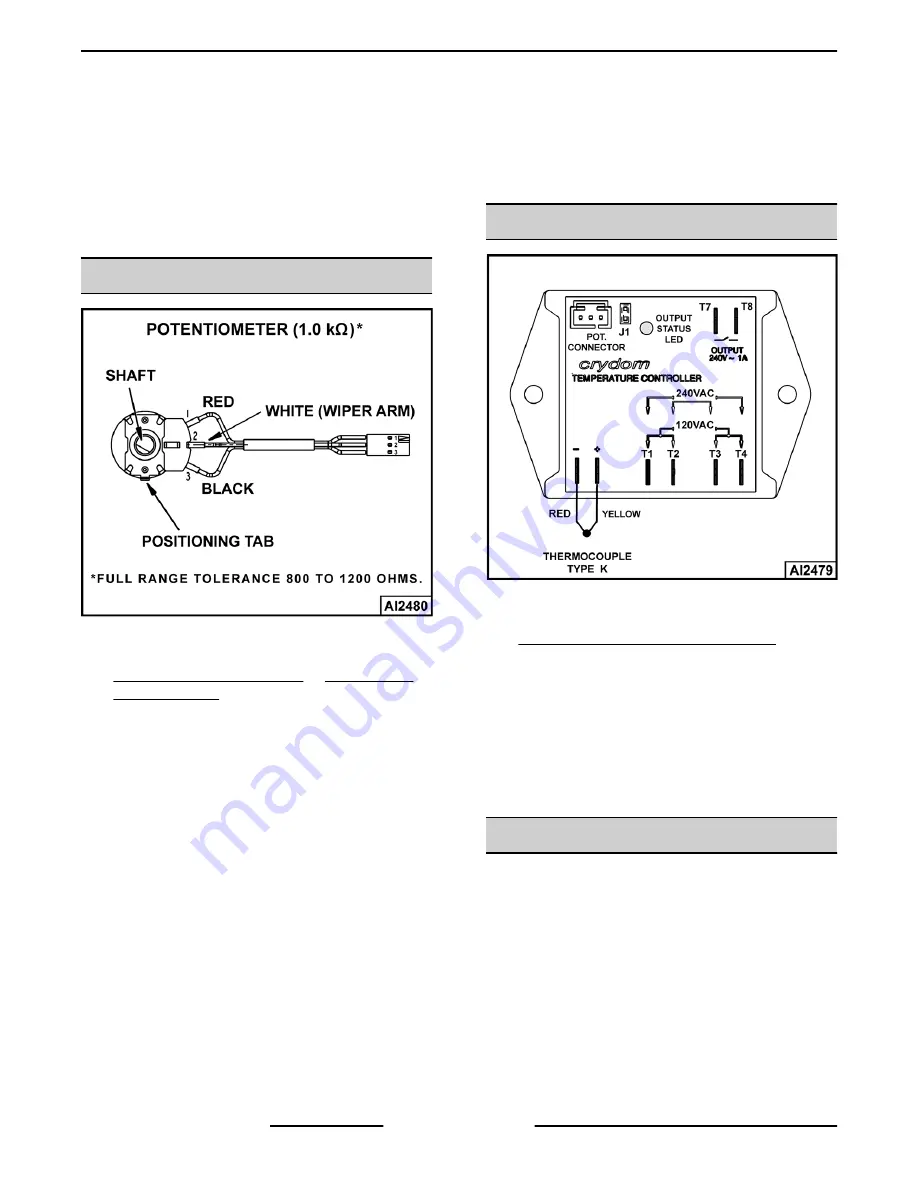

POTENTIOMETER TEST

Fig. 34

1.

Access control panel potentiometer by removing

CORNER PANEL (TILTING) or SIDE PANEL

(STATIONARY).

2.

Turn potentiometer shaft fully counterclockwise

to the lowest setting.

3.

Set VOM to measure resistance.

4.

Connect meter leads to the white and black lead

wires on potentiometer terminals.

A.

Resistance should measure approximately

zero ohms.

5.

Slowly turn potentiometer shaft clockwise over

the full range of travel and monitor resistance

change on the meter.

A.

Resistance should measure 800 to 1200

ohms with shaft turned fully clockwise.

B.

If the resistance value increased smoothly

without sudden drops or spikes and the full

travel resistance value is within tolerance

then potentiometer is functioning properly.

C.

If the resistance value did not increase

smoothly but had drops or spikes over the

full travel range then potentiometer is not

functioning properly. Install a replacement

potentiometer and check for proper

operation.

THERMOCOUPLE TEST

Fig. 35

1.

Access temperature controller as outlined in

ELECTRICAL PANEL COMPONENTS.

2.

Remove thermocouple lead wires from

temperature controller.

3.

Check the thermocouple for a measurable

resistance (approximately 5 to 10 ohms at room

temperature). If meter reads an overload (OL)

condition (open), or zero ohms (short) replace

the thermocouple and check temperature

controller for proper operation.

VENTING

NOTE:

This procedure outlines venting the reservoir

jacket to remove air for proper heat transfer to the

kettle contents.

K Series Gas Kettles 2/3 Jacketed Stationary and Tilting - SERVICE PROCEDURES AND ADJUSTMENTS

F45461 Rev. B (1117)

Page 20 of 48