8.

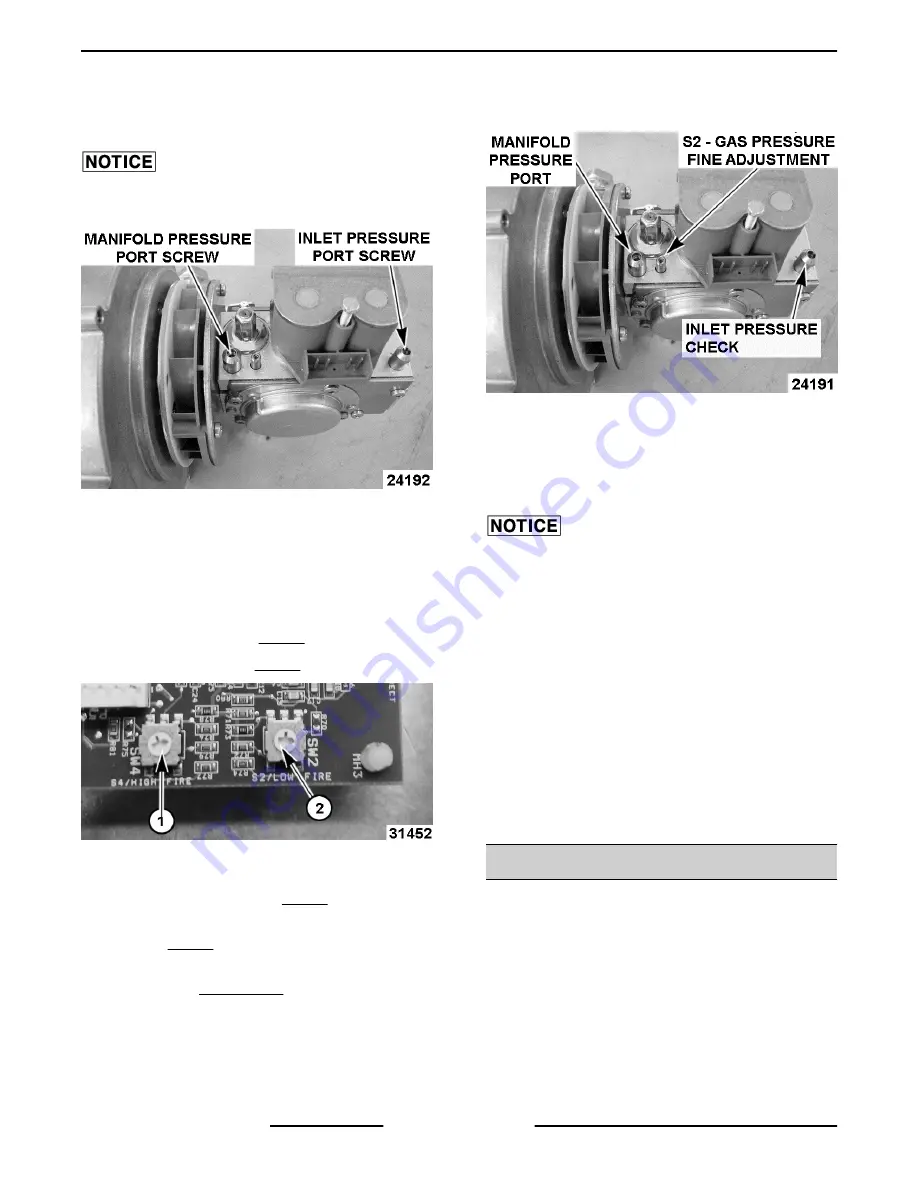

Verify incoming gas supply line pressure is

7“ Water Column (natural gas) and 11” Water

Column (propane).

If inlet pressure is excessive, contact the local gas

supply company to adjust incoming line pressure.

Fig. 43

9.

Verify combustion blower motor speed, control

board settings.

NOTE:

The head of the arrow cut out in the center will

designate the rotary switch setting. "F" and "8" are

designations on the potentiometer.

•

High Fire = F (1, Fig. 44)

•

Low Fire = 8 (2, Fig. 44)

Fig. 44

10. Turn fine adjustment screw on gas valve

clockwise all the way in. (Fig. 45)

11. Adjust gas valve fine adjustment screw for type

of gas. (Fig. 45)

A.

If unable to achieve correct pressure, then

replace GAS VALVE. Preset S2 - gas

pressure fine adjustment screw on the

replacement valve. Turn screw fully

clockwise until it stops.

•

Propane:

Turn fine adjustment screw on

gas valve counterclockwise 9 turns.

•

Natural Gas:

Turn fine adjustment screw on

gas valve counterclockwise 15 turns.

Fig. 45

12. Turn temperature control to

“BOIL”

and turn on

power switch to initiate ignition series.

13. After a warmup of 10 minutes begin sampling flue

gas with a calibrated analyzer.

Flue gasses must be checked with a combustion

analyzer. Combustion limits are listed below. If the

burner system fails to meet these requirements,

please call Steam Technical Support immediately.

Insert sampling probe into flue discharge, located

towards the rear of kettle. Ensure the probe is inserted

in such a way that the sample gas is not diluted. Place

the probe 1-2 inches below the discharge.

14. Make further adjustments to fine adjustment

screw if needed to obtain CO2 reading of 10.5%

to 12.0% (Natural Gas) or 12.0% to 13.5%

(propane).

15. Verify combustion analyzer reports CO air free of

less than 400ppm (.04%). If not, turn fine

adjustment screw CW to lower CO.

SPARK IGNITION TEST

If the ignition control module is not generating a spark

or the spark is not sufficient to light kettle burner,

perform the following test.

K Series Gas Kettles 2/3 Jacketed Stationary and Tilting - SERVICE PROCEDURES AND ADJUSTMENTS

F45461 Rev. B (1117)

Page 26 of 48