Fig. 11

4.

Remove insulating sleeve from thermocouple

wires and retain for use on replacement

thermocouple.

Installation

1.

Slide insulating sleeve over thermocouple wires.

2.

Apply a thin coating of heat transfer and anti-

seize compound to the thermocouple probe tip

and mounting nut threads.

3.

Route thermocouple probe through the front

opening in griddle frame and lay it on top of

burner mounting panel.

4.

From rear of griddle, thread thermocouple probe

into the mounting hole in griddle plate and stop

when probe tip touches the plate. Torque the

mounting nut to a maximum of 25 in-lbs.

Do not over tighten or damage to the

thermocouple probe may occur. Due to the aluminum

plate core, it is also possible to create a raised area

over the probe if overtightened.

5.

Insert rear mounting tab on thermocouple shield

into the support bracket on the bottom of griddle

plate.

6.

Route thermocouple wires through the opening

in burner shield assembly.

7.

8.

Check TEMPERATURE CONTROLLER

CALIBRATION.

PILOT (RADIANT BURNER)

Disconnect the

electrical power to the machine and

follow lockout / tagout procedures.

Shut off the gas before servicing the

unit.

All gas joints disturbed during

servicing must be checked for leaks. Check with a

soap and water solution (bubbles). Do not use an open

flame.

1.

2.

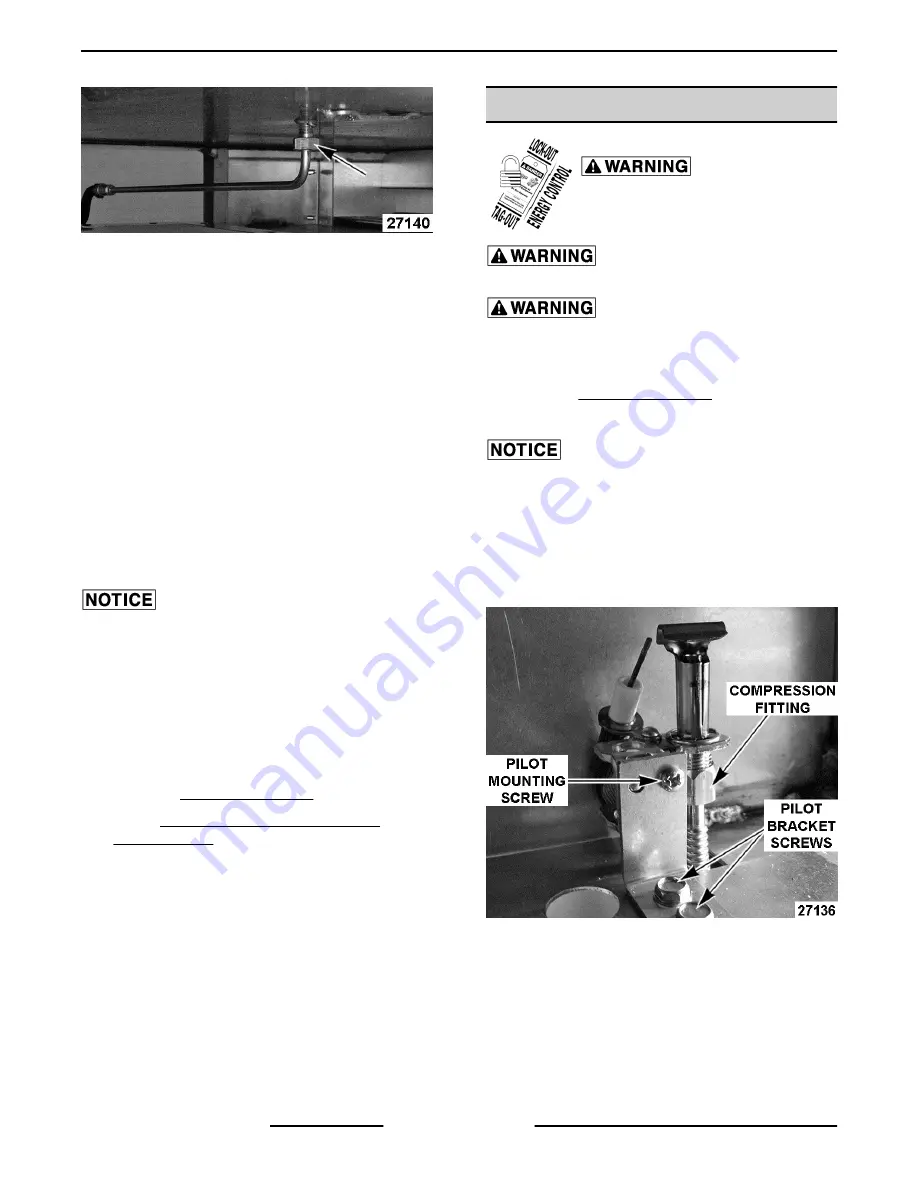

Disconnect compression fitting from pilot.

When disconnecting compression fitting

for the pilot, support bracket to prevent bending.

3.

Remove pilot and mounting bracket from the

burner mounting panel.

4.

Pull spark wire through the hole in control

mounting panel and remove pilot from griddle.

5.

Remove pilot from pilot mounting bracket.

Fig. 12

6.

Reverse procedure to install.

NOTE:

When installing, verify spark gap is 1/8".

VCCG Series Heavy Duty Gas Griddle - REMOVAL AND REPLACEMENT OF PARTS

F45533 (1014)

Page 8 of 26