30

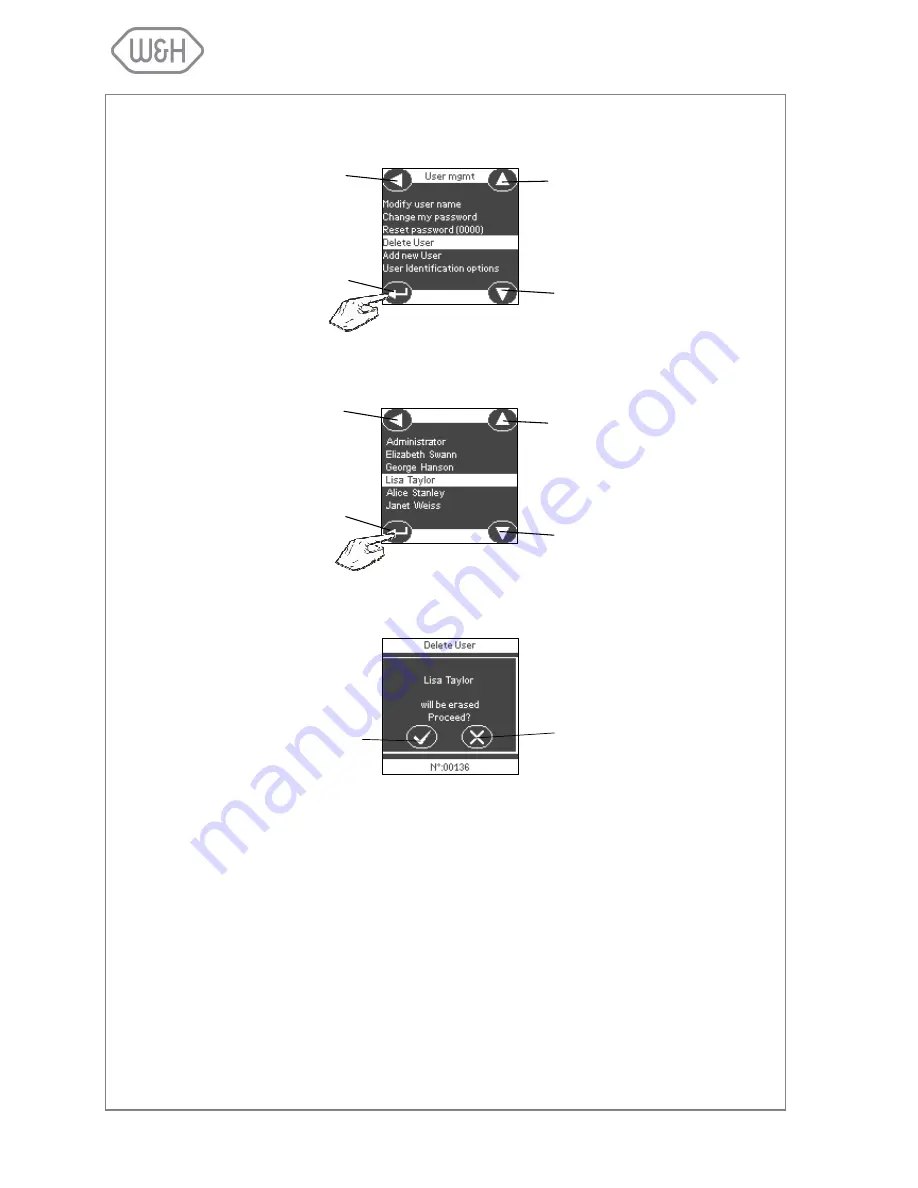

6.9.5 Deleting a user

To delete the name of a user who no longer uses the sterilizer, proceed as follows:

1) Scroll through the menu options and select the “Delete user” option.

2) Select the user to be deleted and confirm

3) Confirm the operation

Abort and return

to previous

screen

Confirm the choice

Scroll down

Scroll up

Abort and return

to previous

screen

Confirm the choice

Scroll down

Scroll up

Abort and return

to previous

screen

Confirm deleting

Summary of Contents for Lisa

Page 1: ...Instruction for use UM009ENG LISA FULLY AUTOMATIC 201 10 Rev 4...

Page 2: ......

Page 77: ......