Page 10 of 34

SCU-138-P-2230

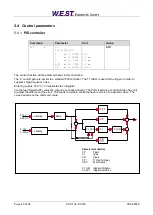

3.2 Typical system structure

This minimal system consists of the following components:

(*1)

Proportional valve

(*2)

Pulse transmitter

(*3)

Speed control unit SCU-138-P

(*4)

Interface to PLC

3.3 Method of operation

This speed control module is controlled via an analogue command signal (from plc, joystick or potentiometer),

a PWM Signal or a fix programmed command value. An ENABLE signal (24 V typical) activates the functions

and if error-free operation this is reported via a READY output. Now the device is in power amplifier mode.

The control loop is initiated by a digital START input. Therefore, the actual value is read by an encoder. If us-

ing two solenoids the closed loop controller gets activated directly with the ENABLE signal. The digital START

input is used for switching the solenoids in this mode (DIR).

The integrated standard features are configured on the various parameters.

In case of a fault the power output stage will be deactivated and the fault will be indicated via deactivating the

READY output and the flashing READY LED.

Three different modes can be used for the error management. SENS=ON: all faults have to be acknowledged

by the ENABLE input. SENS=AUTO: automatic reset mode for all signal faults. SENS=OFF: fault detection is

suppressed.

The output current is controlled whereby a high accuracy and a good dynamic will be obtained. All customary

proportional valves (up to 2.6 A) could be controlled with this power amplifier.