30

Appendix II

7.2.1

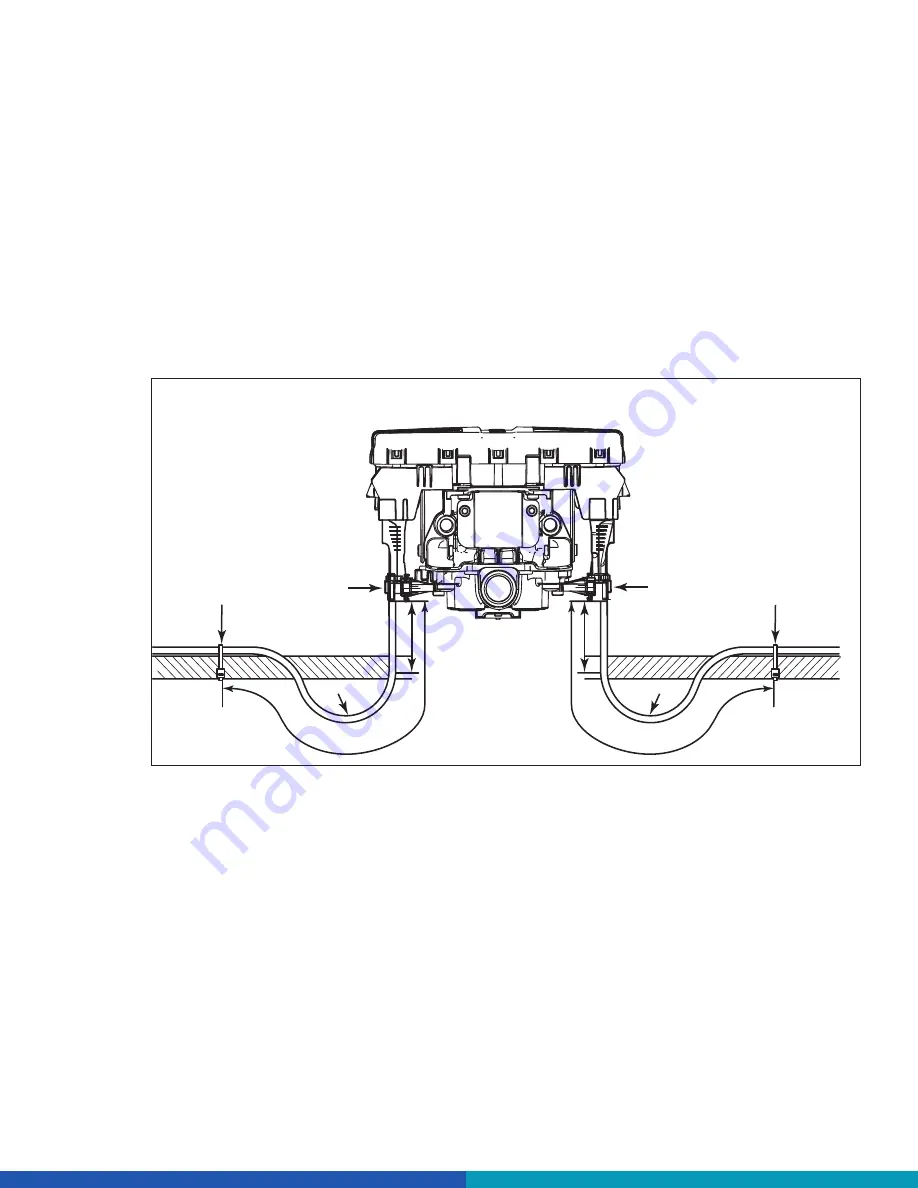

Strain Relief at the ECU — Bracket Mounting

WABCO recommends that cable connections to a component, such as an ECU valve assembly, display

a visible amount of slack in the cable up to the first tie or clip that secures the cable to the trailer structure

or air line. This first anchor point should be a minimum 6-inches (152 mm) of cable length from the cable/

component connection and maximum of 12-inches (305 mm). This applies to all sensor, power, valve and

GIO cables. Regardless of whether zip ties or cable clips are used, cables should be secured at intervals

not greater than 18-inches (457 mm) to avoid cable vibration.

Ideally, cables should be affixed to the rigid structure of the trailer. A good rule of thumb is to have the bend

of the cable, also known as bend radius, be greater than or equal to ten times the diameter of the cable. If

the cable is 1/4-inch (6.35 mm) in diameter, then the bend should be a minimum of 2-1/2-inches (64 mm).

Refer to figure for the ECU mounting of 2S/1M ABS.

4"

Max.

12"

R

4"

Max.

12"

R

≥

10 x D

R

FASTENER

FASTENER

ZIP TIE

ZIP TIE

Bend radius (R) equal to

or greater than 10 times

cable diameter (D).

R

≥

10 x D

First fastener must be

a minimum 6 inches (152 mm)

and a maximum of 12-inches

(305 mm) from connector.

BRACKET MOUNTING - ECU REAR VIEW

4017108a

ABS 2S/1M