28

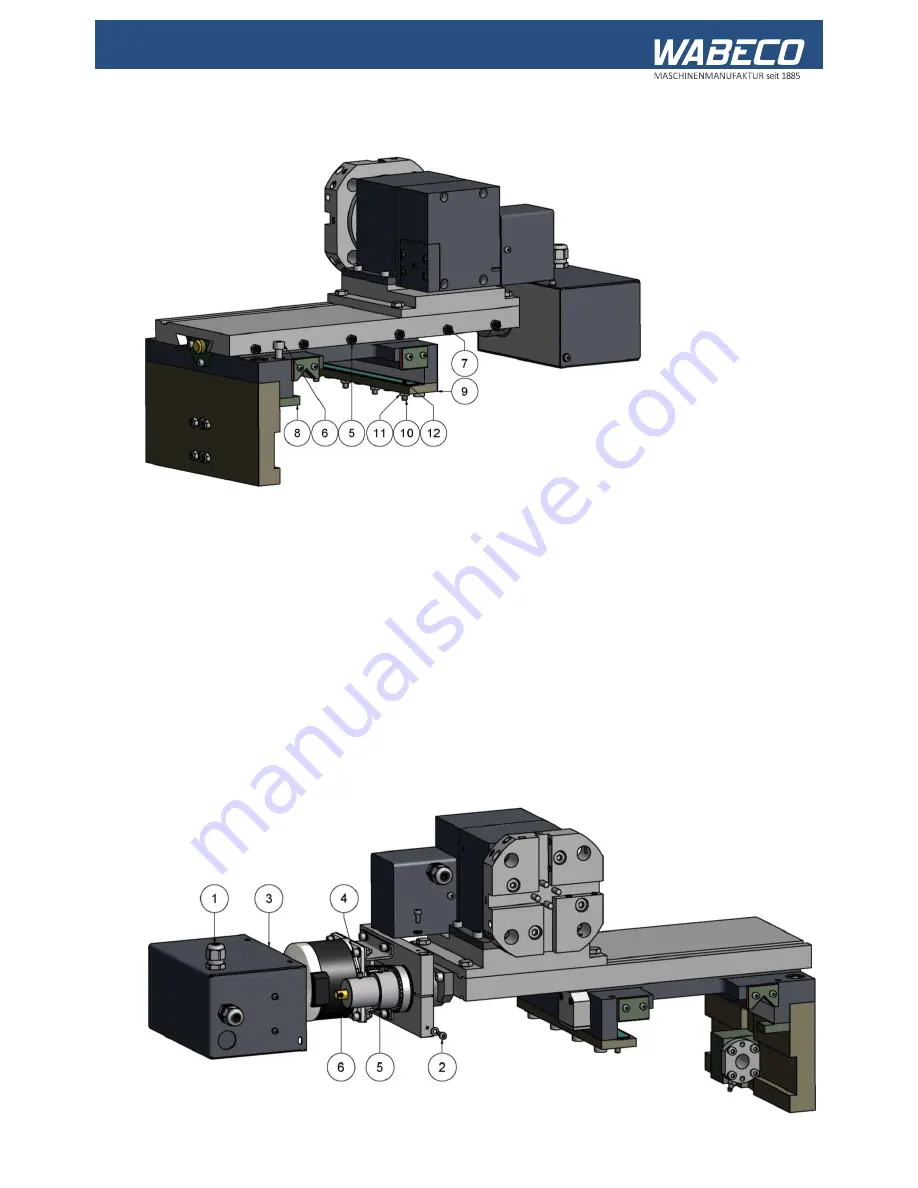

11. Tool slide

The possibly occurring axial clearance of spindle (6) can be adjusted in spindle bearings.

If adjustment is required, please proceed as follows:

1. Open cable conduit (1) far enough for the cable to pulled through easily.

2. Loosen the four screws (2)

3. Pull off hood (3) from motor support plate by simultaneous release of motor cable.

4. Release set screw (4)

5. Turn belt wheel (5) clockwise until there is no more axial clearance

6. Refasten set screw (4)

7. The spindle (6) has to turn easily after subsequent adjustment

8. Reassemble parts in reverse sequence after adjustment

Summary of Contents for CC-D6200 hs

Page 1: ...Operating Instructions CNC lathe With slant bed CC D6200 hs ...

Page 17: ...17 4 Specifications regarding the machine 4 4 Dimensions ...

Page 25: ...25 8 Lubrication oft he machine ...

Page 34: ...34 16 Drawings and legends 16 1 Headstock with Motor ...

Page 36: ...36 16 Drawings and legends 16 2 Bed with lead screw ...

Page 38: ...38 16 Drawings and legends 16 3 Cross slide with saddle apron ...

Page 40: ...40 16 Drawings and legends 16 4 Tailstock ...

Page 48: ...48 16 Drawings and legends 16 10 Operating console ...

Page 52: ...52 17 Circuit diagram 17 1 Overall connection diagram see legend for circuit diagrams 17 3 ...