15

1.

Important safety notes

1.6

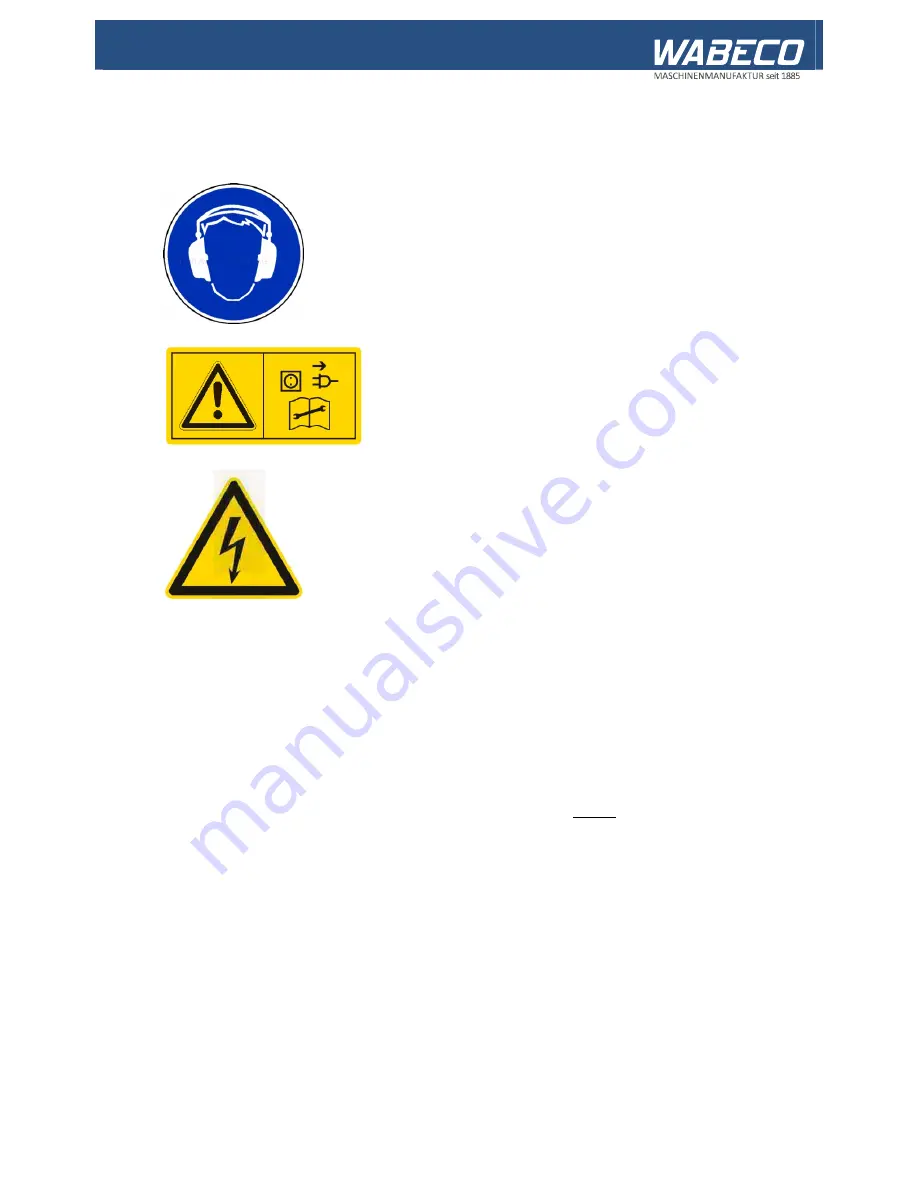

Explanations of the symbols

In the event of an emission noise level as of 80

dB (A) at the workplace, ear defenders must be

worn.

Caution:

Always pull the power plug prior to any

maintenance work!

Read the operating instructions prior to initial

operation or maintenance work!

Caution:

Dangerous electric voltage!

2.

Delivery and set up

The machine is packed with care at the factory.

The following should be checked after delivery:

1. Whether the packaging shows damages to be reported or

2. Whether the machine shows transportation damages to be reported If this is the case, we ask you

to communicate this information immediately. Subsequent claims cannot be recognised.

The boring and milling machine must be set up on a suitable, even and firm surface.

Suitable

surfaces are, for example

:

■

A tool cabinet (available optionally)

■

A separate workbench with a level surface (spirit level) that is strong enough to carry the weight of

the machine without bending.

■

A steel plate with a level surface (spirit level)

The machine must be screwed securely to the surface it is set up on. There are holes in the base of

the machine that are designed for this purpose.

Good working results and low-vibration operation

can only be ensured when the prerequisites for fixture as set out above are maintained.

Summary of Contents for CC-F1200 high speed

Page 42: ...42 6 Fitting and removing the tools 1 2 3 4 5...

Page 68: ...68 17 Drawings and legends 17 2 Electronic hood with 1 4 kW motor 17 2 2 CC F1200 CC F1210...

Page 70: ...70 17 Drawings and legends 17 3 Milling head with 1 4 kW motor...

Page 72: ...72 40 1 51004008 0002 Mounting pin 17 Drawings and legends 17 4 Milling head with 2 0 kW motor...

Page 74: ...74 17 Drawings and legends 17 4 Milling head with 2 0 kW motor...

Page 76: ...76 17 Drawings and legends 17 5 Z stand with vertical skid with trapezoidal threaded spindle...

Page 82: ...82 17 7 Lateral drive for z axis with trapezoidal threaded spindle 17 Drawings and legends...

Page 84: ...84 17 8 Cross slide support with trapezoidal threaded spindle 17 Drawings and legends...

Page 94: ...94 17 Drawings and legends 17 11 Z stand with vertical skid with ball screw spindle...

Page 100: ...100 17 Drawings and legends 17 13 Lateral drive for z axis with ball screw spindle...

Page 102: ...102 17 Drawings and legends 17 14 Cross slide support with ball screw spindle...

Page 114: ...114 17 Drawings and legends 17 20 Operating console for 1 4 kW motor...

Page 116: ...116 17 Drawings and legends 17 20 Operating console for 1 4 kW motor...

Page 118: ...118 17 Drawings and legends 17 21 Operating console for 2 0 kW motor...

Page 120: ...120 17 Drawings and legends 17 21 Operating console for 2 0 kW motor...

Page 122: ...122 17 Drawings and legends 17 22 Bracket arm for operating console...

Page 124: ...124 17 Drawings and legends 17 23 Industrial monitor and folio keyboard...