35

10

.

Applications

10.1

Longitudinal and transverse turning

i

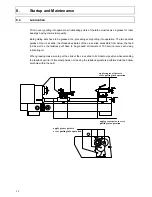

For the reason of the power at the turning chisel take care that the tool is short

and fast fixed. If the lever arm is to long the turning chisel curves and springs

back. The cutting part enters uneven into the workpiece and is producing a

waved surface.

Take care that the turning chisel is placed on the middle of the turning piece.

The control of the height position of the middle of the workpiece is done with the

live lathe center in the tailstock.

For the regulation of the height position of the turning chisel use with straight

sheet steel pieces.

10.2

Thread cutting and automatic feed

10.2.1 General

note

The tread turning chisel is a form turning chisel with the profile of the thread to be cut.. It is ground

according to jigs (diagram 1) and must be adjusted exactly to the middle of the workpiece as,

otherwise, the profile of the thread would be distorted.

In order to obrain the correct position of the flanks of the thread to the axis of the workpiece, the

grinding jig is put against the work piece and the turning tool is adjusted in accordance with it

(diagram 1). For this purpose the jig is pushed successively on to both flanks of the turning tool.

The feed of the thread turning tool is effected over the lead screw and must correspond to the

thread pitch.

Setting the thread turning chisel

90°

Change gears:

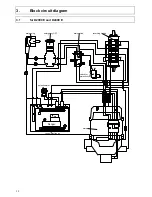

The connection between the feed gear mechanism and the lead screw is made by the translating

gear wheels (extras at D2000, D2000E and D2400) included in the attachments. By setting various

combinations of gears it is possible to cut a metric right-hand thread with a pitch of 0,4 mm - 3 mm

and an inch-system right-hand thread with a pitch of 10Z/1" - 32 Z/1" (see table). (For left hand

threads see the section "Gear pair, left-hand thread"). The various distances of the axes between

the gears can be adjusted by swiveling the quadrant and readjusting the quadrant bolts.