11

6.

Start-up and Maintenance

6.6 Headstock

The headstock is firmly attached to the guide bars. Inside the headstock, the work spindle is run on

two adjustable precision tapered roller bearings.

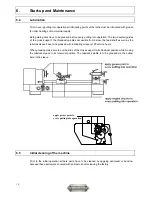

adjustment nut

ON -OFF lever

for automatic feed

If the bearings need to be readjusted, please proceed in the following manner:

1. Loosen the stud bolt in the adjustment nut. The adjustment nut is located at the rear end of the

work spindle.

2. Turn the adjustment nut clockwise until the bearings run free of play again (the work spindle can

easily be turned by hand).

3. Re-Tighten the stud bolt.

i

Roller bearings adjusted too tightly become useless after a short period

Automatic feed:

There is an on-off lever for the automatic feed on the front of the headstock. The machine is

delivered with the wheels for feed 0.085 mm/rev. attached.

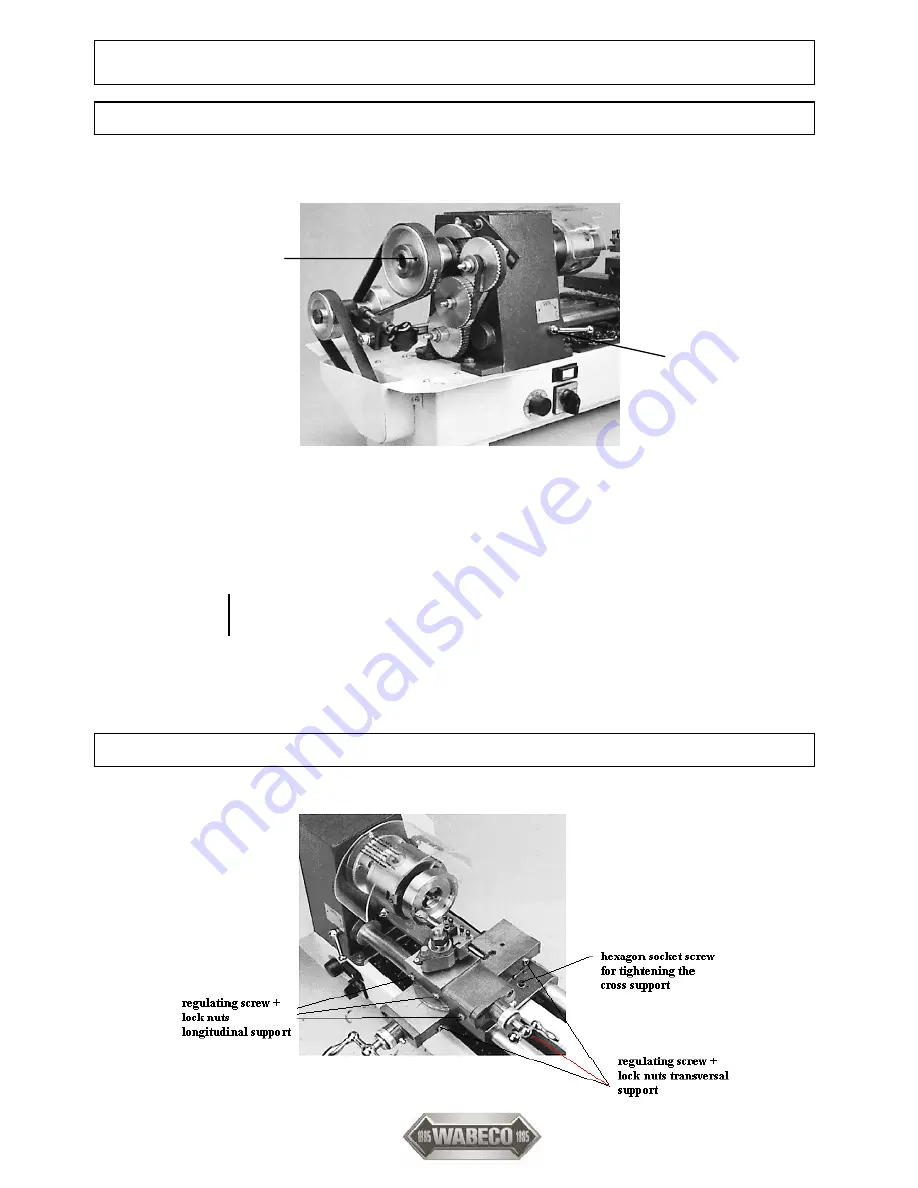

6.7 Cross

support

The cross support consists of a longitudinal and a transversal support. It is equipped with

ajustable

dovetail guides.

Summary of Contents for D2400

Page 5: ...5 1 Machine dimensions 1 1 D2000 1 2 D2400...

Page 6: ...6 1 Machine dimensions 1 3 D3000...

Page 28: ...28 13 Drawings and list of parts 13 3 Lead screw drive for D2400 and D3000...

Page 32: ...32 13 Drawings and list of parts 13 5 Drive with gear transmission for D2000...

Page 34: ...34 13 Drawings and list of parts 13 6 Cross support...