14

7. Speed

regulation

7.1.3

Speed setting for working with Brass, Copper

workpiece-

Ø

approx. r.p.m..

cutting speed m/min

10 mm

2300

80

20 mm

1270

80

40 mm

640

80

60 mm

425

80

80 mm

320

80

100 mm

250

80

7.2 Speed

change

Rotational speed range 45 - 2300 min-1:

The rotational speed of the work spindle is infinitely variable between 45 and 400 r.p.m. in the 1

st

step or in the 2

nd

step between 200-2300 r.p.m using the potentiometer on the front side of the

machine.

speed setting at the potentiometer

1. step r.p.m.

2. step r.p.m.

10 45

200

20 105

350

30 175

740

40 260

1050

50 325

1440

60 360

1650

70 400

1860

80 460

2120

90 490

2160

100 500

2300

Rotational speed 45 - 400 r.p.m.:

The drive belt must be relocated if the lower speed level with a minimum speed of 45 r.p.m. is

required.

Proceed as follows:

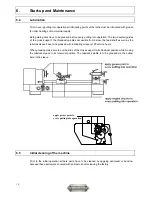

Remove the protective cover and release the drive belt by unscrewing the clamping nut and turning

the star handle clockwise until the drive belt can be relocated. Then re-tighten the drive belt in the

reverse sequence of steps.

clamping nut

star handle

potentiometer

rotational speed 45-400 rpm

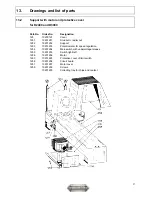

Summary of Contents for D2400

Page 5: ...5 1 Machine dimensions 1 1 D2000 1 2 D2400...

Page 6: ...6 1 Machine dimensions 1 3 D3000...

Page 28: ...28 13 Drawings and list of parts 13 3 Lead screw drive for D2400 and D3000...

Page 32: ...32 13 Drawings and list of parts 13 5 Drive with gear transmission for D2000...

Page 34: ...34 13 Drawings and list of parts 13 6 Cross support...