46

6.

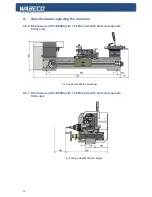

Thread cutting and automatic feed

6.3

Use of change gears

mm

0.4

0.5

0.7

0.75

0.8

1.0

1.25

1.5

1.75

2.0

2.5

3.0

3.5

4.0

5.0

7.0

A1

48

48

48

48

48

48

48

48

48

48

48

48

24

24

24

24

A2

16

20

14

18

16

14

20

36

28

40

40

48

28

40

40

28

C

40

40

20

24

20

14

16

24

16

20

16

16

16

20

16

16

C1

16

16

16

16

16

16

16

16

16

16

16

16

16

16

16

32

D

140

140

140

140

140

140

140

140

140

140

140

140

120

120

120

120

F

140

140

140

140

140

140

140

140

140

140

140

140

140

140

140

120

*

Z/1"

10

11

12

13

14

16

18

19

20

24

26

28

32

36

40

A1

34

34

34

34

34

34

34

34

34

34

34

34

34

34

34

A2

36

36

36

36

36

36

14

34

*

18

24

18

18

18

14

18

C

20

22

24

26

*

28

32

14

36

20

32

26

*

28

32

28

40

C1

16

16

16

16

16

16

16

16

16

16

16

16

16

16

16

D

120

120

120

140

140

140

120

140

120

120 120 120

120

120

120

F

140

140

140

140

140

140

140

140

140

140 140 140

140

140

140

7.

Maintenance

A long lifetime of the machine will depend on the appropriate care and maintenance.

■

All maintenance and repair tasks may only be carried out with the grounded plug pulled.

■

The machine must be cleaned after each use.

■

If the machine is set up in a wet room, all exposed parts must be oiled after each use to prevent

corrosion.

■

Always lubricate all moving parts well.

■

In the event of bearing or skid play, immediately adjust in order to prevent it from destroying the

bearing or skid guide.

Approximately every 100 operating hours

Clean the carbon brushes and collector of the drive motor (1.4 kW) with a piece of coarse

sandpaper.

Remove approximately 0.1 mm from the carbon brushes, then smooth out the contact surface with

fine sandpaper.

■

Check the tension of the poly V and gear belt and adjust if necessary.

■

Check the play in the guides and feed spindles and set if necessary.

Summary of Contents for D6000

Page 76: ...76 18 Drawings and legends 18 3 Protective hood drive 2 0 kW motor...

Page 78: ...78 18 Drawings and legends 18 4 Electronic console 2 0 kW motor...

Page 86: ...86 18 Drawings and legends 18 10 Bed with lead screw with trapezoidal threaded spindle...

Page 90: ...90 18 Drawings and legends 18 11 Bed with lead screw with ball screw spindle...

Page 94: ...94 18 Drawings and legends 18 13 Tool skid Transverse skid...

Page 96: ...96 18 Drawings and legends 18 14 Tool skid Lock plate...

Page 98: ...98 18 Drawings and legends 18 15 Tool skid Longitudinal skid...

Page 100: ...100 18 Drawings and legends 18 16 Transverse skid with lock plate with ball screw spindle...

Page 102: ...102 18 Drawings and legends 18 17 Tailstock...

Page 104: ...104 18 Drawings and legends 18 18 Motor for control of the x axis...

Page 106: ...106 18 Drawings and legends 18 19 Motor for control of the z axis...

Page 108: ...108 18 Drawings and legends 18 20 Operating console for 1 4 kW motor...

Page 110: ...110 18 Drawings and legends 18 20 Operating console for 1 4 kW motor...

Page 112: ...112 18 Drawings and legends 18 21 Operating console for 2 0 kW motor...

Page 114: ...114 18 Drawings and legends 18 21 Operating console for 2 0 kW motor...

Page 116: ...116 18 Drawings and legends 18 22 Bracket arm for operating console...

Page 118: ...118 18 Drawings and legends 18 23 Industrial screen and membrane keyboard...

Page 138: ...138 19 Circuit diagram 19 9 Multiphase motor with end stop...

Page 154: ...154 23 Safety cabin optional 23 8 Drawing and legend...

Page 163: ...163 26 Tensioning bracket with milling machine table optional 26 7 Drawing and legend...