POW-R-DRIVE II

8

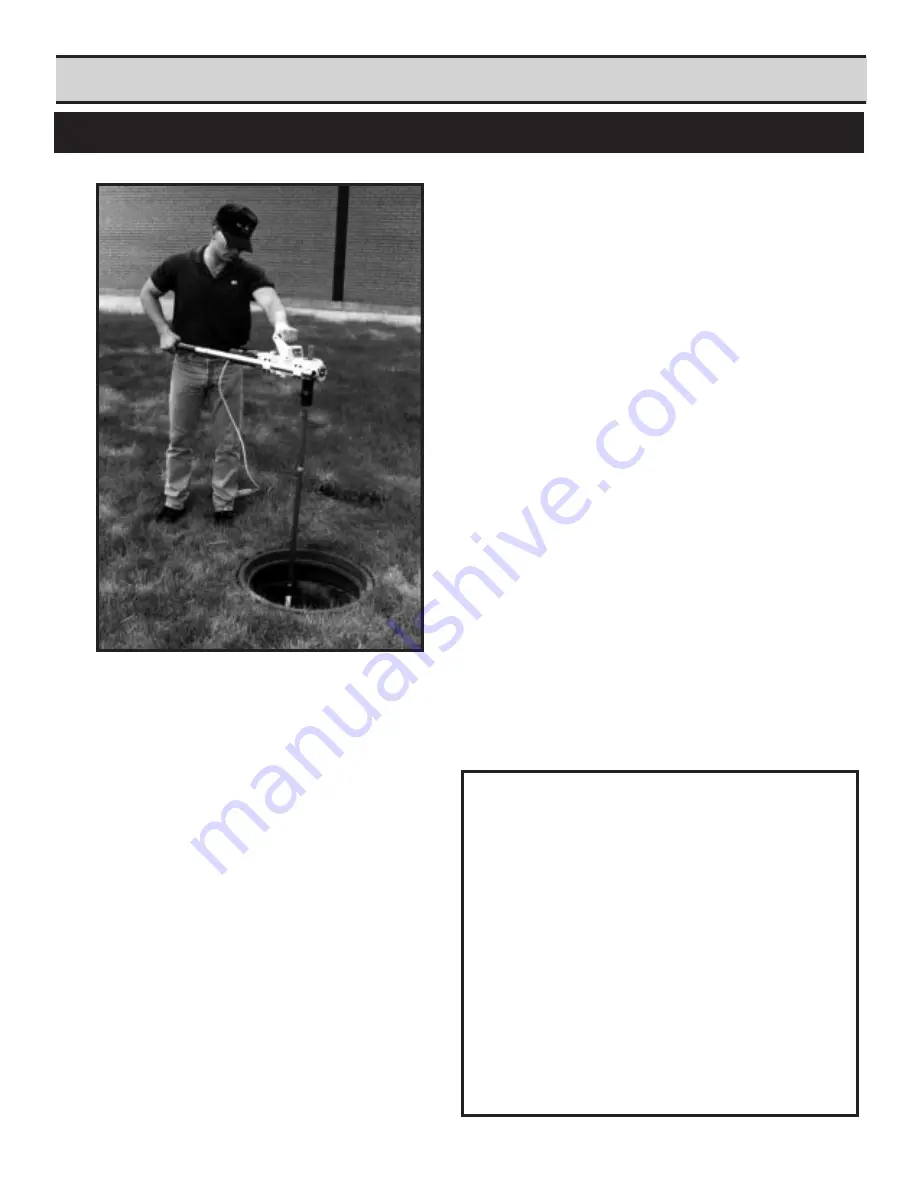

Valve Maintenance Procedure

A valve that has not been operated for a number of

years needs to be closed by using a series of up and

down motions. Occasionally, crews attempting to

close a difficult valve use a T-handle or a cheater bar,

applying a great deal of pressure in one direction

simply to force the valve closed. The correct way to

exercise a valve is to begin with a steady amount of

torque in the direction necessary to close the valve,

moving through five to ten rotations, Then the

direction should be reversed for two or three revolu-

tions, followed by five or ten more turns in the closing

direction. This procedure should be repeated until

full closure is attained.

The reason for the cautious approach is that tuber-

culation and sediment have probably built up on the

gates, stem, and slides. If this material is compacted

while the valve is being closed, the torque required

to close the valve continues to build as the material

SECTION IV

SET-UP AND OPERATION

is loaded. By using the procedure described, water in

the system can flush the debris that has broken loosen

away from the gate and slide. The stem is exercised

through the series of up and down motions. Once the

valve has been fully closed, it should be opened a few

turns so that the higher velocity water flowing under the

gates can move the remainder of the sediment down-

stream.

After the valve is reopened, it should be turned in the

closing direction one or two revolutions. Thus, the next

time the valve is operated, it will not be necessary to

start with a nut and stem jammed against the bonnet,

and there will be no guesswork about which way to turn

the nut because the valve will be free. Also, if it is

inadvertently turned the wrong way, one or two turns

can be made before a positive stops occurs, and by

reversing direction, full operation of the valve can be

effected.

Using the Pow-R-Drive II machines to operate valves is

easier on the valve because a steady turning torque is

applied rather than jerky motions. This prevents the

stem breakage that is sometimes caused by turning the

valve by hand. Also, more valves can be turned in less

time. A further advantage is that information about each

valve can be generated automatically by the revolution

counter and torque gauges for inclusion on permanent

records.

HOW TO DETERMINE AN

UNKNOWN VALVE ROTATION:

When the direction to turn the valve stem is not

known, select a rotation direction and proceed

with caution. If resistance is felt, immediately

reverse the rotation. Continue this procedure,

reversing direction when resistance is felt,

until a free turning direction is achieved. Docu-

ment the direction, open or closed position,

and number of turns required.

Summary of Contents for POW-R-DRIVE II

Page 2: ......

Page 7: ...POW R DRIVE II 7 Set Up Operating Procedures Section IV ...

Page 17: ...POW R DRIVE II 17 SECTION V MISCELLANEOUS CHARTS AND GRAPHS ...

Page 20: ......

Page 21: ...POW R DRIVE II 21 SECTION VI MAINTENANCE ...

Page 23: ...POW R DRIVE II 23 SECTION VII PARTS LISTS EXPLODED VIEW DRAWINGS ...

Page 25: ...25 ...

Page 27: ...27 ...

Page 29: ...11 080 00 181 061 041 ...

Page 31: ...31 081 ...

Page 33: ...33 081 ...

Page 35: ...35 ...

Page 37: ...37 ...

Page 38: ...POW R DRIVE II Electrical Schematics Eibenstock Milwaukee Electric RevolutionCounter Wire 38 ...

Page 39: ...39 ...

Page 40: ...POW R DRIVE II 40 SECTION VIII VALVE EXCERCISING LOG ...