WACHS TRAV-L-VAC 300

11

SECTION IV

SET-UP AND OPERATION

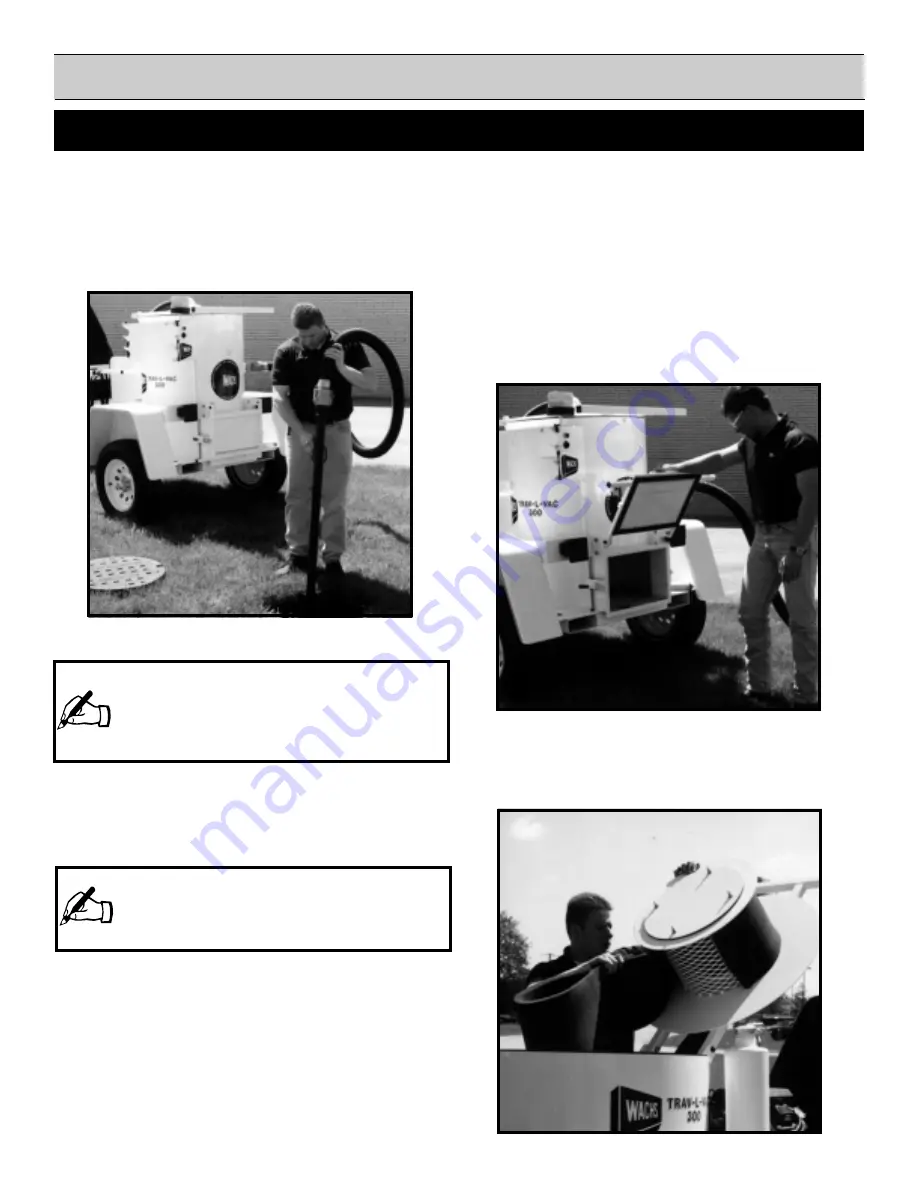

extract debris until valve box is empty or until holding

tank is full. (Fig. 3)

5. If the unit fills with liquid to its limit, the high liquid level

switch will automatically shut off the engine. Before

restarting unit, the holding tank must be drained. If this

is not done, unit will not start.

6. After the vacuum operation is over, run engine for several

minutes to clear out any water which may have reached

the blower.

7. Consult the manufacturer for special operating sugges-

tions concerning use in freezing weather.

TLV DUMPING PROCEDURES:

Liquids:

1. Shut down engine.

Figure 3

NOTE:

If a clog occurs, shake suction hose. If clog

remains, open the vacuum diverter valve to remove

vacuum from suction hose. Disconnect the hose

from the TLV. Either use a ram to dislodge clogged

debris or reverse suction hose ends.

NOTE:

If removing heavier or solid debris, the high

liquid level switch

may not

cause the unit to shut

down. Periodically inspect the holding tank to avoid

over filling.

Figure 4

2. Position vacuum system over designated dumping area.

3. If the material collected is primarily liquid, the holding

tank drain plug should be used to remove holding tank

contents.

4. Once liquid has drained, open dump gate and remove

any remaining debris. ( Fig. 4)

5. Clean primary filter prior to next use. Filter can be

cleaned with only water, however, mild soap and water

are recommended if possible. ( Fig. 5)

TLV DUMPING PROCEDURES (CONT.):

Solids:

Figure 5

Summary of Contents for TRAV-L-VAC 300

Page 2: ......

Page 6: ......

Page 7: ...WACHS TRAV L VAC 300 7 SECTIONIV SET UP AND OPERATING PROCEDURES...

Page 9: ...WACHS TRAV L VAC 300 9 SECTION IV SET UP AND OPERATION INSTALLATION DIAGRAM...

Page 13: ...WACHS TRAV L VAC 300 13 SECTIONV MAINTENANCE...

Page 16: ...WACHS TRAV L VAC 300 16 SECTIONV MISCELLANEOUS CHARTS AND GRAPHS...

Page 17: ...WACHS TRAV L VAC 300 17 TRAV L VAC 300ACOUSTIC EVALUATION SOUND DECIBLE LEVEL DIAGRAM 10 FT...

Page 18: ...WACHS TRAV L VAC 300 18 TRAV L VAC 300PERFORMANCE CHARTS...

Page 19: ...WACHS TRAV L VAC 300 19 BILL OF MATERIAL...

Page 21: ...WACHS TRAV L VAC 300 21...