WACHS TRAV-L-VAC 300

20

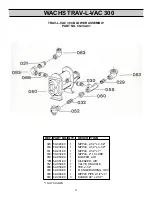

056

59-079-00

2

HOSE CLAMP 1/2"

*057

62-091-00

1

SHUT DOWN DECAL

*058

59-116-00

2

TLV 300 DECAL

*059

59-086-00

1

MAINTENANCE DECAL

*060

59-088-00

1

WATER LEVEL DECAL

*063

67-108-00

1

S/N PLATE

*064

67-110-00

1

OPERATING LABEL

*065

67-116-00

1

GAS LABEL

*066

67-117-00

1

SAFETY LABEL

*067

62-091-00

1

SHUT DOWN DECAL

*068

59-117-00

1

OPEN MACHINE LABEL

*069

59-118-00

1

TLV-300 CRATE

*070

59-098-00

1

LABEL, EAR PROTECTION

*071

59-099-00

1

EYE PROTECTION LABEL

073

59-102-00

2

DUMP GATE HINGE

074

59-103-00

2

FILTER LID HINGE

075

59-010-00

2

FENDER

076

59-013-00

2

FENDER BRACE

077

59-022-00

1

TONGUE

078

59-075-00

1

AXLE

079

59-080-00

2

WHEELS

080

59-085-00

10

WHEEL NUTS

081

59-090-00

2

CENTER CAP

082

59-095-00

1

TRAILER LIGHT LH

083

59-100-00

1

TRAILER LIGHT RH

084

59-105-00

1

TRAILER WIRE HARNESS

*085

59-110-00

2

"S" HOOKS

*086

59-115-00

2

TONGUE GROMMET

*087

59-082-00

15'

CABLE WRAP

*088

59-084-00

2

NO STEP STICKER

*089

59-089-00

1

TRAILER VIN PLATE

090

59-096-00

2

RECIEVER PULL PIN

*091

59-097-00

2

AMBER REFLECTOR

092

59-120-00

1

STROBE LIGHT

093

59-121-00

1

STROBE SWITCH

094

59-122-00

1

ACCESSORY OUTLET

095

62-083-00

1

ELBOW, 90° x 2-1/2"

096

59-003-00

1

DUMP GATE

097

59-004-00

1

FILTER LID

098

59-025-00

1

WAND DOOR

099

59-021-00

1

GUARD, TOP

100

59-027-00

1

GUARD, SIDE

101

59-006-00

1

FILTER DRUM PLATE

*102

59-107-00

2

HOSE CLAMPS

103

59-108-00

1

RETRACTABLE JACK

104

59-109-00

1

SNAP RING

*105

59-112-00

10'

TUBING LOOM

*106

59-113-00

5

WIRE CLIPS, ADHESIVE

FASTENERS

*1

90-091-30

4

1/2-13 x 3" HHCS

*2

4

BLOWER WASHERS

3

90-095-52

16

1/2" FLAT WASHERS

4

90-095-55

10

1/2" LOCK WASHERS

5

90-095-01

10

1/2-13 HEX NUTS

6

90-091-45

6

1/2-13 x 4-1/2" HHCS

*7

90-071-20

6

3/8-16 x 2" HHCS

TRAV-L-VAC 300 BILL OF MATERIAL

PART NO. 59-000-01 & 59-401-01

REF.

PART NO.

QTY.

DESCRIPTION

REF.

PART NO.

QTY.

DESCRIPTION

01

59-300-01

1

TLV FRAME

02

59-302-01

1

BLOWER W/ SILENCER

03

59-033-01

1

ENGINE

*04

59-034-00

1

MUFFLER

05

59-035-00

1

TACH / HOURMETER

06

59-036-00

1

FUEL TANK

07

59-037-00

3

V-BELT SHEAVE

08

59-038-01

1

BUSHING, V-BELT

09

59-039-00

1

BUSHING, V-BELT

010

59-040-00

2

V-BELT

011

59-041-00

1

BELT, TENSIONER

012

59-042-00

1

TENSIONER SHAFT

013

59-043-00

1

IDLER BUSHING

014

59-044-00

2

NYLON WASHER

015

59-045-00

2

NYLON WASHER

017

62-095-00

1

RAIN CAP

018

14-136-00

1

BATTERY

019

59-047-00

1

SWITCH, LIQUID LEVEL

*020

59-048-00

12'

LID, SEAL

*021

59-049-00

1

DRAIN PLUG

*022

59-050-00

4

1-1/2" SQ. CAP

*023

59-051-00

6

1" CAP

*024

59-052-00

2

THREADED ROD

025

62-070-00

1

END CAP

026

59-053-00

2

FILTER STRAP

027

59-054-00

2

STRAP, VACUUM HOSE

028

59-055-00

1

SILENCER STRAP

030

62-054-00

1

FILTER

031

62-055-00

1

POLYURETHANE FILTER

032

62-801-00

1

POLYURETHANE FILTER

033

59-057-00

2

2-1/2" COMB. NIPPLE

*034

59-058-00

1

DUST CAP

*035

59-059-00

1

MALE COUPLING

*036

59-060-00

1

TERMINAL COVER

*037

59-061-00

1

2" BALL VALVE

*038

59-062-00

1

TEE

039

59-063-00

4'

HOSE VACUUM

041

59-056-00

1

DUMP SEAL

*042

59-066-00

1

CONNECTOR, BULLET

*043

59-067-00

1

CONNECTOR, BULLET

*044

59-068-00

5

CONDUIT 1/2" PLASTIC

*045

59-069-00

2

CONNECTOR, NYLON

*046

59-070-00

5

MOUNTING, BRACKET

047

59-404-08

1

7/8" x 6-1/2' WAND

59-404-12

1

1-1/4" x 6-1/2' WAND

59-404-15

1

1-1/2" x 6-1/2' WAND

59-119-20

1

2" x 6-1/2' WAND

048

59-026-08

2

7/8" WAND INSERT

59-026-12

2

1-1/4" WAND INSERT

59-026-15

2

1-1/2" WAND INSERT

59-026-20

2

2" WAND INSERT

*049

59-071-00

1

MUFFLER GUARD

*050

59-072-00

1

EXHAUST DEFLECTOR

*051

59-073-00

18"

CHAIN

*052

59-074-00

4

"S" HOOKS

59-074-01

2

"S" HOOKS

053

59-076-00

20

SELF TAP SCREWS #10

055

59-078-00

4'

1/4" FUEL LINE

*

= NOT SHOWN

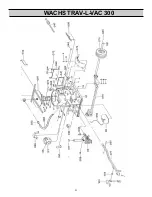

Summary of Contents for TRAV-L-VAC 300

Page 2: ......

Page 6: ......

Page 7: ...WACHS TRAV L VAC 300 7 SECTIONIV SET UP AND OPERATING PROCEDURES...

Page 9: ...WACHS TRAV L VAC 300 9 SECTION IV SET UP AND OPERATION INSTALLATION DIAGRAM...

Page 13: ...WACHS TRAV L VAC 300 13 SECTIONV MAINTENANCE...

Page 16: ...WACHS TRAV L VAC 300 16 SECTIONV MISCELLANEOUS CHARTS AND GRAPHS...

Page 17: ...WACHS TRAV L VAC 300 17 TRAV L VAC 300ACOUSTIC EVALUATION SOUND DECIBLE LEVEL DIAGRAM 10 FT...

Page 18: ...WACHS TRAV L VAC 300 18 TRAV L VAC 300PERFORMANCE CHARTS...

Page 19: ...WACHS TRAV L VAC 300 19 BILL OF MATERIAL...

Page 21: ...WACHS TRAV L VAC 300 21...