BA 1001/1501/2001 us – Edition 3.3 * * 12001b540.fm

5-37

Maintenance

Clean and adjust the fuel injection p

ump

7

●●

Check and adjust the injection pressure of the in

jection nozzles, clea

n the injection needle

s/nozzles

●●

Check and adjust injection time

8

●●

Empty diesel fuel tank

9

●●

Check battery electrolyte

. A

dd

distilled water if necessary

●●

●

Check alternator, starter and electric

connections, bearin

g play and function

●●

Check preheating system and electric connections

●●

Pressure check of

primar

y pressure limiting valves

10

●●

●

Check tracks fo

r cracks and cuts

●●

Check track tension. Retighte

n if necessary

●●

Check bearing play of tread rollers,

track carrier rollers, front idlers

●●

Check piston rods

for damage

●●

Check screws for tightness

11

●●

●

Check pin lock

●●

Check line fixtures

●●

Check indicator lights for correct function

●●

●

Couplings, dirt pile-up on hydrau

lic syste

m dust caps if necessary

●●

Check insulating mats in engine compartment for damage/condition

●●

Check labels and Operator’s Manual

for completeness and condition

●●

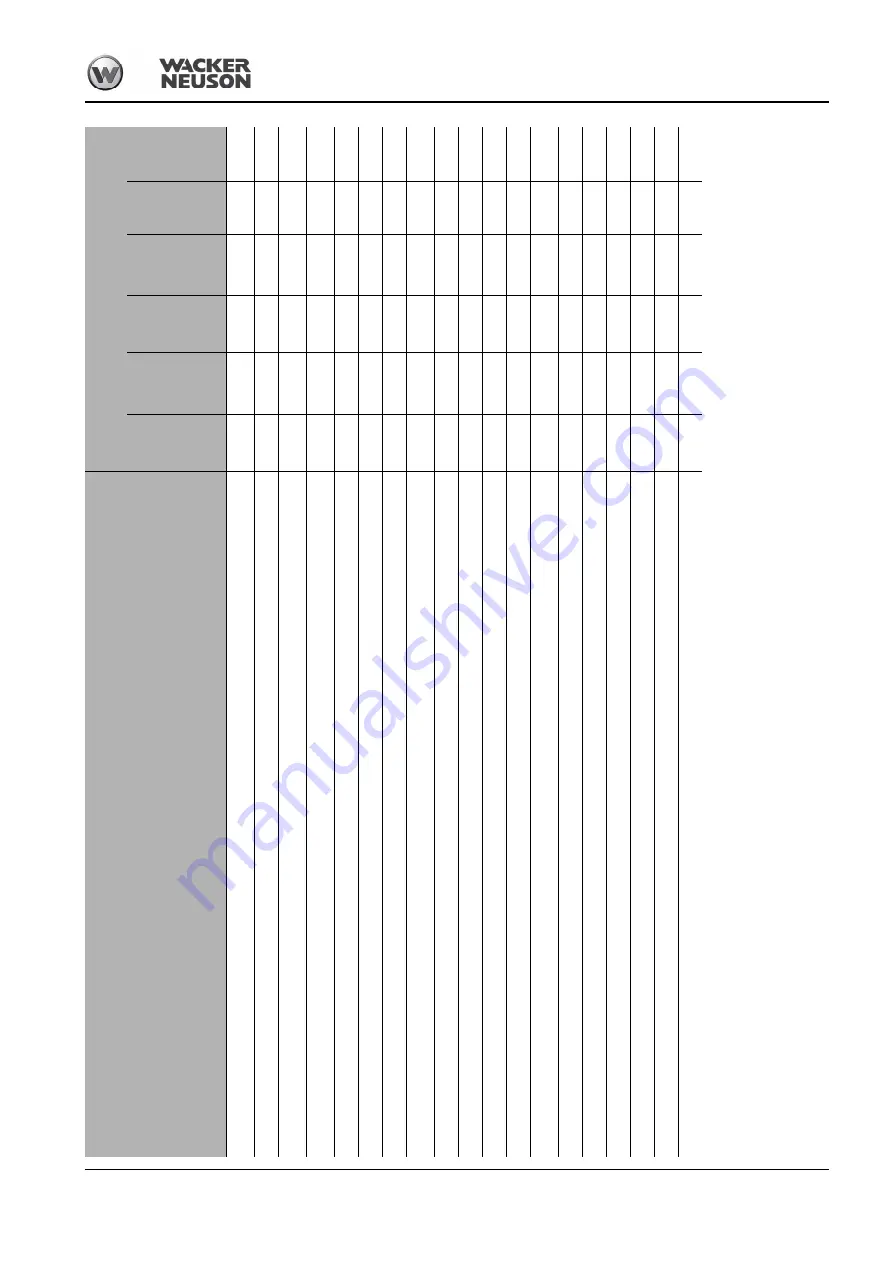

5.15

Maintenance plan 1001 – 1501 (overview)

Work description

For servicing and maintenance on the attachment, p

lease refer

to the ope

ration and maintenance manual of the attachment

manufacturer as well.

Maintenance plan/ope

ratin

g h

our

s (o/h

)

Maintenance

(once a day)

Every 50 o/h

Every 500 o/h

Every 1000 o/h

once a year

Customer

Wacker Neuson

service center