BA 50Z3/6003 en – Edition 4.3 * 5003b530.fm

5-49

Maintenance

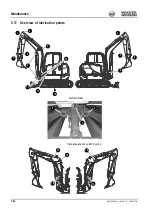

Powertilt lubrication points (option)

Perform maintenance of the Powertilt unit once a day with the other maintenance work for

the machine.

Perform visual checks for possible defects, damage or cracks.

Remove all dirt on and around moving parts.

Apply grease via grease nipples

15

.

Lubrication points of hydraulic quickhitch (option)

Notice!

Before picking up an attachment, the driver must ensure that it can be hitched cor-

rectly by removing all dirt on either claw of the quickhitch.

Perform maintenance on the quickhitch once a day with the other maintenance

work for the machine.

Perform visual checks for possible defects, damage or cracks.

Remove all dirt on and around moving parts.

The claws must be clean and slightly greased.

Apply grease to the friction surfaces of the lock mechanism via 2 grease nipples

16

on

either side of the quickhitch (see

).

Before starting work, check the acoustic signal. You must be able to hear the acoustic sig-

nal as you actuate the switch.

15

Fig. 321: Powertilt lubrication points

Fig. 322: Quickhitch lubrication points

16

Summary of Contents for 50Z3

Page 35: ...BA 50Z3 6003 en Edition 4 3 5003b110 fm 1 23 Introduction Overview of safety labels ...

Page 56: ...2 16 BA 50Z3 6003 en Edition 4 3 5003b210 fm Safety instructions ...

Page 178: ...3 122 BA 50Z3 6003 en Edition 4 3 5003b340 fm Operation ...

Page 190: ...4 12 BA 50Z3 6003 en Edition 4 3 5003b410 fm Troubleshooting ...

Page 254: ...5 64 BA 50Z3 6003 en Edition 4 3 5003b560 fm ...

Page 265: ...BA 50Z3 6003 en Edition 4 3 5003b610 fm 6 11 Specifications 6 16 Dimensions model 50Z3 ...

Page 267: ...BA 50Z3 6003 en Edition 4 3 5003b610 fm 6 13 Specifications 6 17 Dimensions model 50Z3 VDS ...