Commissioning

Putting into operation with Honda engine 7.3

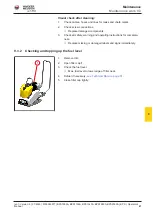

1

A

1.

Move the fuel cock

1

into position

A

.

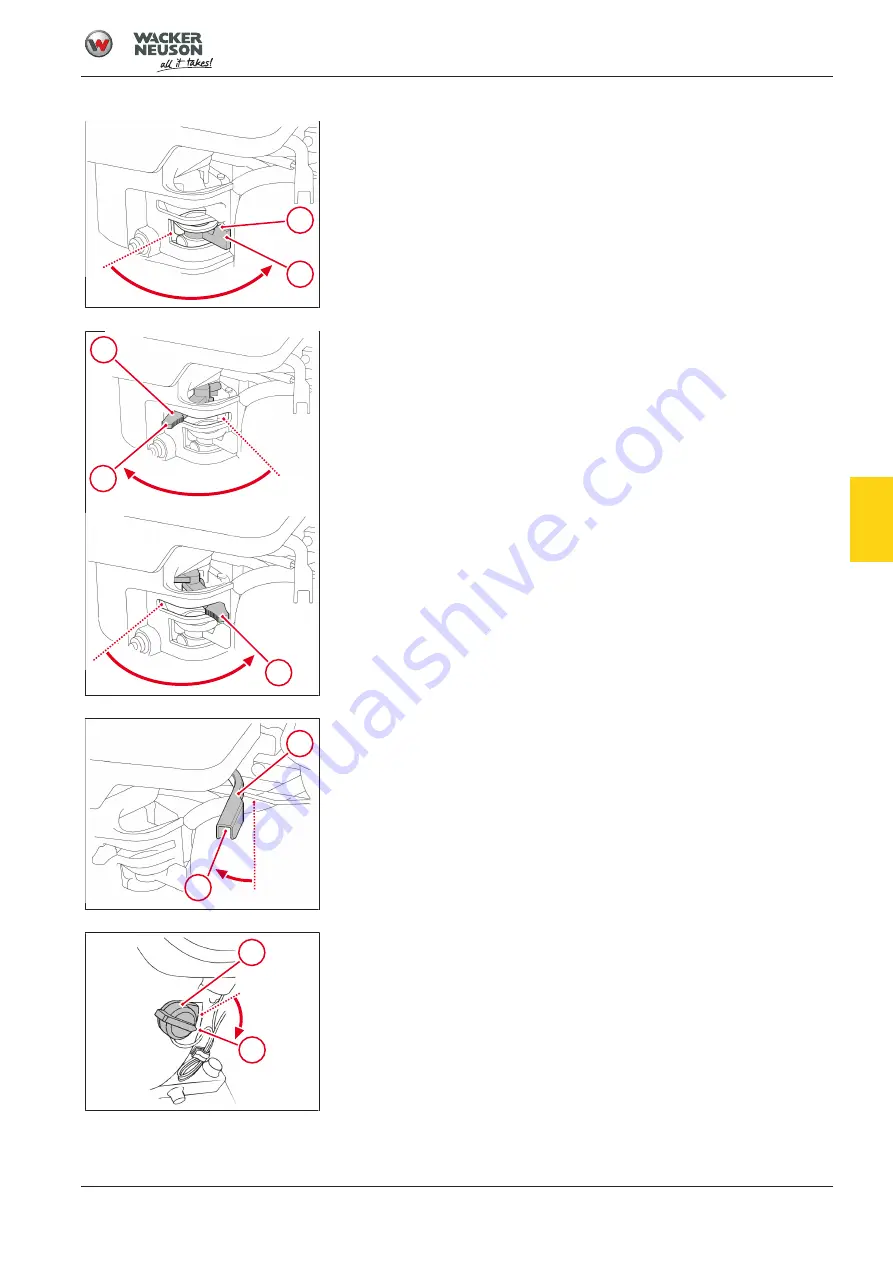

A

2

B

2.

Move choke lever

2

to position

A

when the engine is cold.

3.

Move the choke lever to position

B

when the engine is warm.

3

A

4.

Move the throttle lever

3

into position

A

.

4

A

5.

Move the engine switch

4

into position

A

.

[en] | Version: 5 | 01/2023 | 5100060577 | BPS1030A, BPS1135A, BPS1340A, BPS1550A, BPS2050A | BPS | Operator’s

Manual

35

7