wc_tx004063gb_FM10.fm

38

Rammer

Troubleshooting

3.8

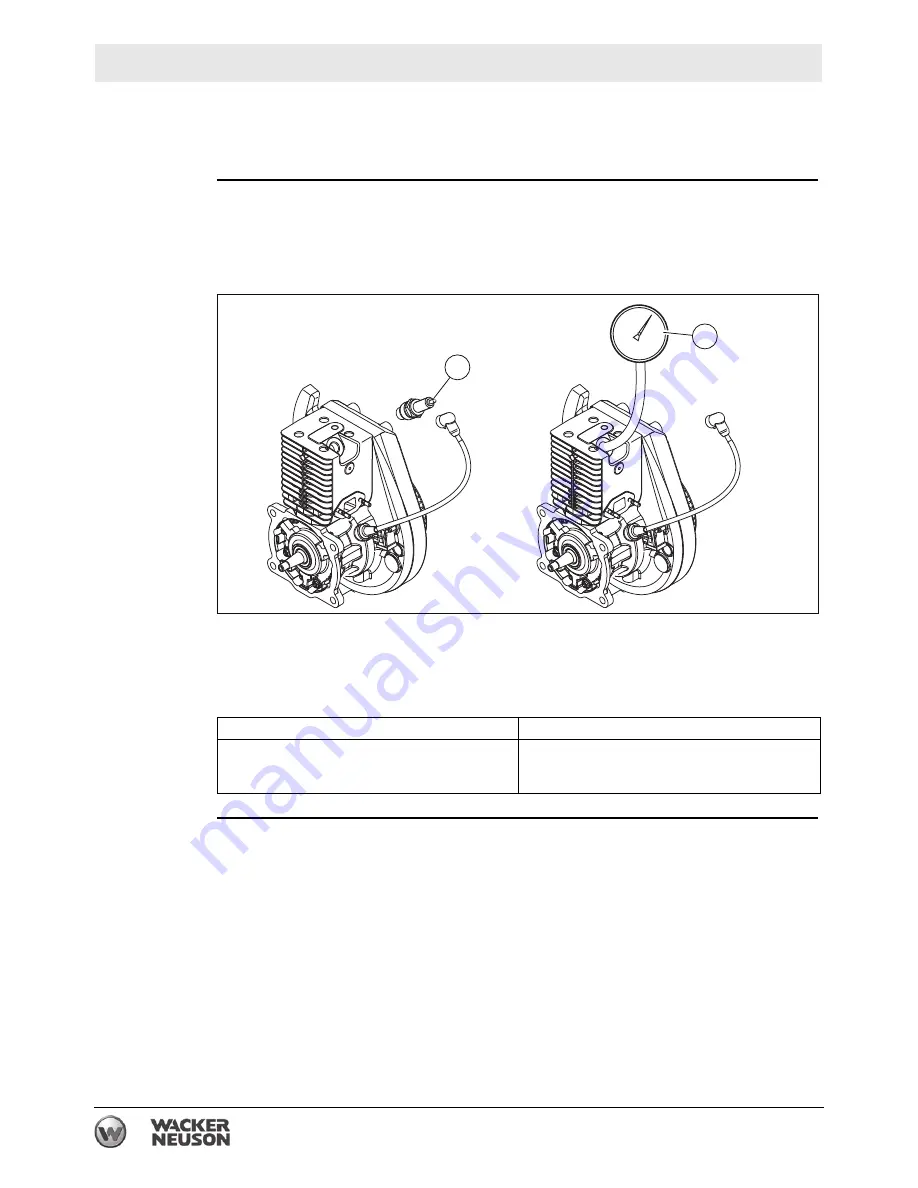

Checking Engine Compression

Requirements

■

Compression tester

■

Torque wrench

Note: The procedure below applies to the WM 80 engine. For other engines, see

the engine manufacturer for more information.

Procedure

Perform the procedure below to check engine combustion.

1. Remove the spark plug

(a)

.

2. Install the compression gauge

(b)

into the cylinder.

3. Pull the starter rope several times and measure the pressure on the gauge.

Is 6 – 9.6 Nm (90 – 140 psi) measured?

Result

The engine compression has now been checked.

Yes ____

No ____

The engine compression is OK.

Re-install the spark plug. Torque the spark

plug to 35–41 Nm (25.8–30.2 ft.lbs.).

There is too little compression.

Rebuild the engine.

wc_gr012948

a

b

Summary of Contents for BS 50-4s, BS 50-4As

Page 1: ...Repair Manual Vibratory Rammer 5100018465 01 1015 5 1 0 0 0 1 8 4 6 5 EN...

Page 6: ...wc_tx004061gb_FM10 fm 6 Rammer Foreword...

Page 10: ...Table of Contents Rammer wc_br5100018465_FM10TOC fm 10...

Page 180: ...wc_td000553gb_FM10 fm 180 Rammer Technical Data Notes...

Page 192: ......

Page 193: ......