Operation

BS 65-V

wc_tx000918gb.fm

30

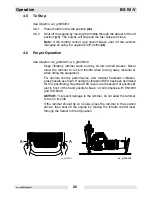

4.9

Adjusting Ramming Stroke

See Graphic: wc_gr000060

When adjusting the ramming stroke, observe the following precautions

to avoid injury to yourself and others.

Adjust stroke with machine standing upright and resting on a firm, level

surface. Do not adjust stroke if the machine is in an unstable position

where it can easily tip or slide.

Always stop engine before adjusting stroke. The clutch could engage,

causing rammer to jump unexpectedly.

Adjustment should be performed by one person and with no one else

near the machine. The tool used to make the adjustment could slip out

of your hands and hit someone standing nearby.

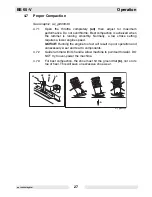

To adjust ramming stroke:

4.9.1

Remove adjusting tool from cover. Open cover.

4.9.2

Check that arrow (a) on center of locking lever is pointing up.

If arrow is pointing down, the spring system is not balanced and could

cause the top half of the rammer to drop unexpectedly while making

the stroke adjustment. To balance spring system, stand behind the

rammer and use guide handle to rock machine back and forth until you

feel the spring system relax. The arrow should now be facing up.

4.9.3

Insert adjusting tool (b) into bore on locking lever. Make sure it is fully

seated so it will not slip out. Steady the rammer by holding guide

handle and use adjusting tool to push locking lever straight down until

it is completely disengaged (refer to Operation 1 in illustration above).

4.9.4

Using the adjusting tool, move locking lever until center arrow is

pointing at the desired stroke setting (Operation 2).

During this adjustment, tension is applied to the spring system. This

tension will release as the locking lever is returned back to its locked

position. When this happens, the rammer will settle, causing the

handle and crankcase to drop down. The movement is slight but

happens quickly. Be aware of this when moving locking lever.

4.9.5

Push or pull the adjusting tool to move the locking lever back to its

locked position (Operation 3). When the locking lever is halfway

between the locked and unlocked position the spring system will settle

and move as described in warning above.

4.9.6

Remove adjusting tool. Close cover and lock it in place with tool.

WARNING

WARNING

WARNING

Summary of Contents for BS 65-V

Page 1: ...Rammer BS 65 V OPERATOR S MANUAL 0176651en 001 0808 0 1 7 6 6 5 1 E N...

Page 2: ......

Page 18: ...Safety Information BS 65 V wc_si000275gb fm 18 3 5 Label Locations wc_gr005418 C P N O M...

Page 29: ...BS 65 V Operation wc_tx000918gb fm 29 Notes...

Page 35: ...BS 65 V Maintenance wc_tx000923gb fm 35 wc_gr005326...