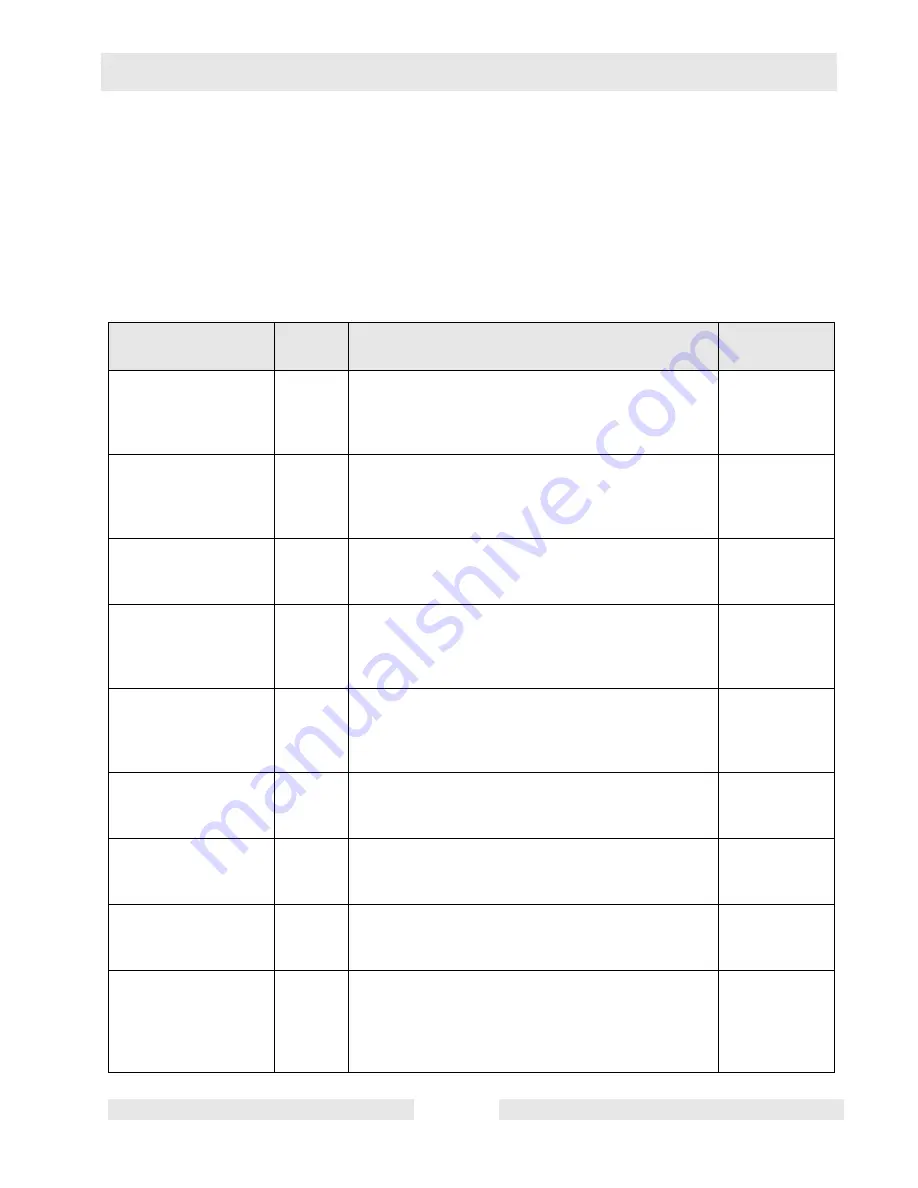

Threadlockers and Sealants

Threadlockers and Sealants

Threadlocking adhesives and sealants are specified throughout this

manual by a notation of “S” plus a number (S#) and should be used

where indicated. Threadlocking compounds normally break down at

temperatures above 175°C (350°F). If a screw or bolt is hard to

remove, heat it using a small propane torch to break down the sealant.

When applying sealants, follow instructions on container. The sealants

listed below are recommended for use on Wacker equipment.

TYPE

( ) = Europe

COLOR

USAGE

PART NO. -

SIZE

Loctite 222

Hernon 420

Omnifit 1150 (50M)

Purple

Low strength, for locking threads smaller than 6 mm

(1/4").

Hand tool removable.

Temp. range, -54 to 149 ° C (-65 to 300 ° F)

73287 - 10 ml

Hernon 423

Omnifit 1350 (100M)

Blue

Medium strength, for locking threads larger than

6 mm (1/4").

Hand tool removable.

Temp. range, -54 to 149 ° C (-65 to 300 ° F)

29311 - .5 ml

17380 - 50 ml

Loctite 271/277

Hernon 427

Omnifit 1550 (220M)

Red

High strength, for all threads up to 25 mm (1”).

Heat parts before disassembly.

Temp. range, -54 to 149 ° C (-65 to 300 ° F)

29312 - .5 ml

26685 - 10 ml

73285 - 50 ml

Loctite 290

Hernon 431

Omnifit 1710 (230LL)

Green

Medium to high strength, for locking preassembled

threads and for sealing weld porosity (wicking).

Gaps up to 0.13 mm (0.005")

Temp. range, -54 to 149 ° C (-65 to 300 ° F)

28824 - .5 ml

25316 - 10 ml

Loctite 609

Hernon 822

Omnifit 1730 (230L)

Green

Medium strength retaining compound for slip or press

fit of shafts, bearings, gears, pulleys, etc.

Gaps up to 0.13 mm (0.005")

Temp. range, -54 to 149 ° C (-65 to 300 ° F)

29314 - .5 ml

Loctite 545

Hernon 947

Omnifit 1150 (50M)

Brown

Hydraulic sealant

Temp. range, -54 to 149 ° C (-65 to 300 ° F)

79356 - 50 ml

Loctite 592

Hernon 920

Omnifit 790

White

Pipe sealant with Teflon for moderate pressures.

Temp. range, -54 to 149 ° C (-65 to 300 ° F)

26695 - 6 ml

73289 - 50 ml

Loctite 515

Hernon 910

Omnifit 10

Purple

Form-in-place gasket for flexible joints.

Fills gaps up to 1.3 mm (0.05")

Temp. range, -54 to 149 ° C (-65 to 300 ° F)

70735 - 50 ml

Loctite 496

Hernon 110

Omnifit Sicomet 7000

Clear

Instant adhesive for bonding rubber, metal and plas-

tics; general purpose.

For gaps up to 0.15 mm (0.006")

Read caution instructions before using.

Temp. range, -54 to 82 ° C (-65 to 180 ° F)

52676 - 1 oz.

Summary of Contents for BTS 930-8340

Page 2: ......

Page 6: ...Table of Contents BTS Repair wc_br0118754enTOC fm 4...

Page 38: ...Torques BTS Repair wc_tx000327gb fm 36...

Page 43: ......